Method of photolyzing seawater by tetraselmis chui to produce hydrogen using fuel cell hydrogen consuming technique

A fuel cell and aquatic hydrogen production technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., to achieve the effects of wide application range, strong comparability, and convenient and quick application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

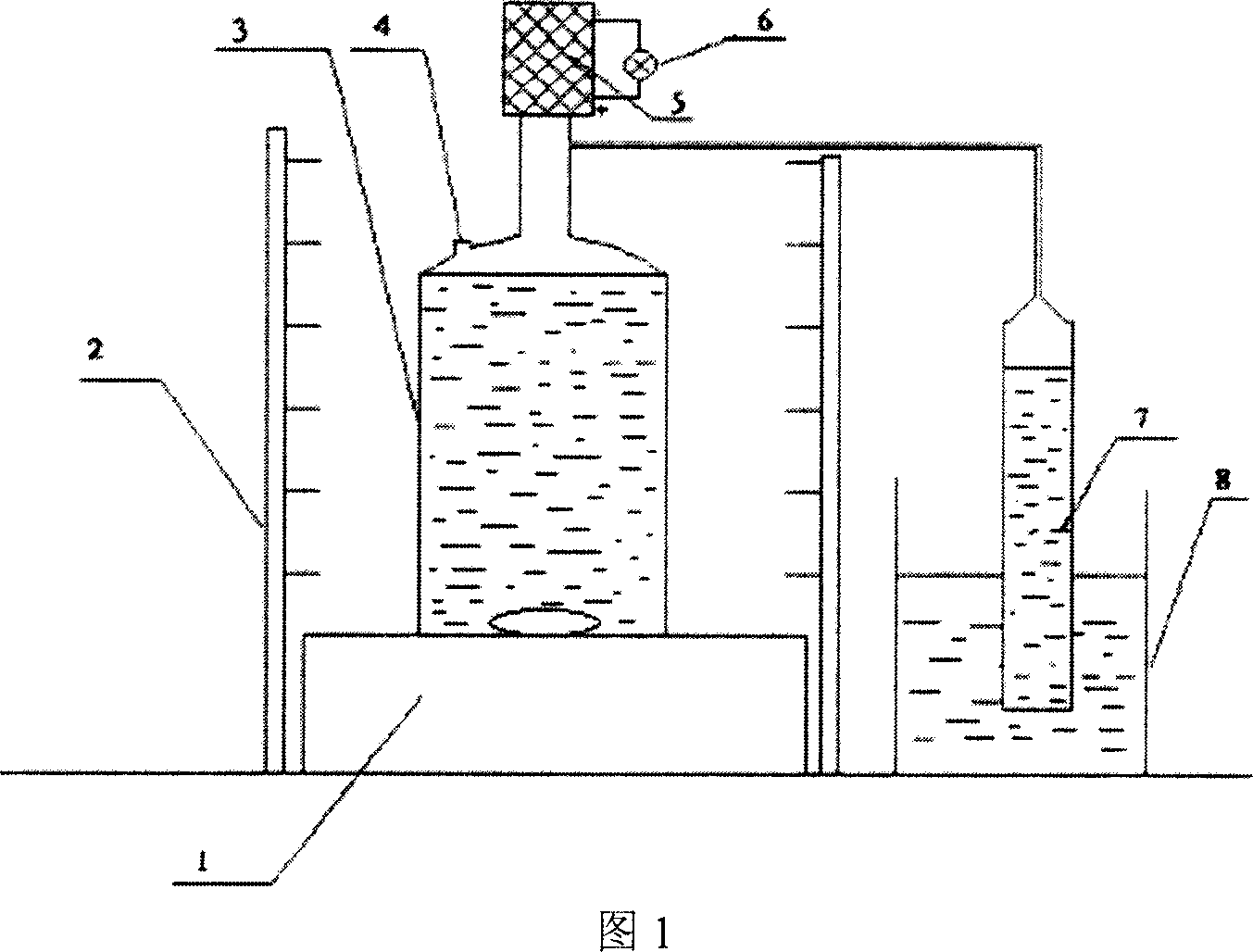

[0035]As shown in Figure 1, it is a schematic diagram of a photobiological hydrogen production system, wherein 3 is a photoreactor, which is made of a glass material, and the gas volume change in the photoreactor 3 is collected and measured in a water tank 8 through a calibration gas sampling tube 7. The hydrogen consumption current of the fuel cell is automatically detected and recorded by the data acquisition and recording system. The subcardiac flat algae were cultured with Kangweifang nutrient salts. After culturing to the late logarithmic growth stage, they were collected by centrifugation until the concentration of the hydrogen-producing algae liquid was 8 million cells / mL. Using the two-step method of photolysis of water to produce hydrogen from flat algae, take a stirred photohydrogen reactor with a volume of 500mL, fill it with algae liquid, seal the bottle mouth, replace the air with nitrogen for 5 minutes, and place it in a 25°C incubator in the dark. Cultured to in...

Embodiment 2

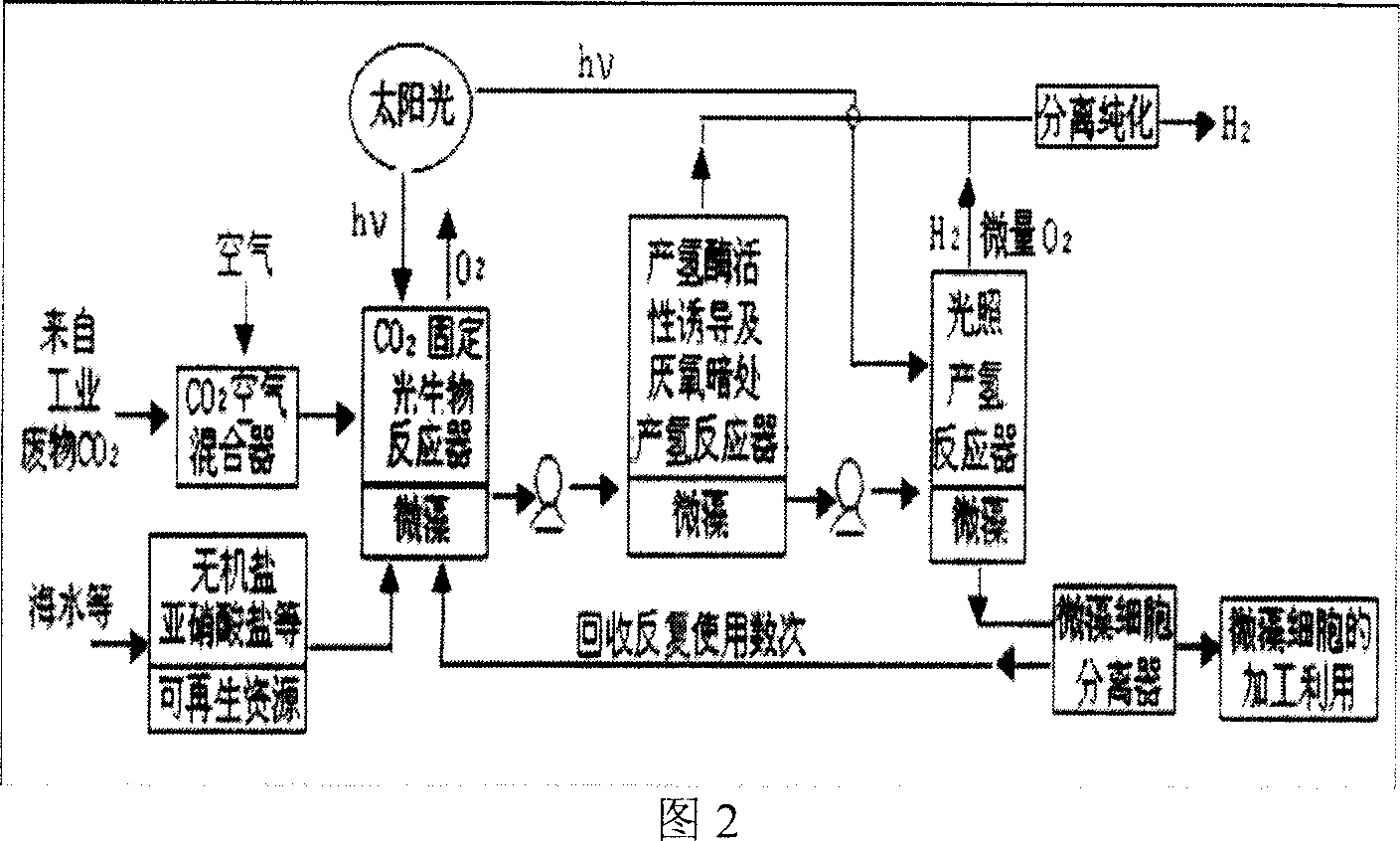

[0039] The subcardiac flat algae are cultivated with Kangweifang nutrient salts. After culturing to the late logarithmic growth stage, they are centrifuged, collected by membrane filtration, or cultured at high density to a concentration of 6 million cells / mL in the hydrogen-producing algae liquid. The method for producing hydrogen by using the two-step method of flat algae to photolyze water is shown in Figure 2. Take a stirred-type photohydrogen production reactor with a volume of 500 mL, fill it with algae liquid, seal the bottle mouth, replace the air with nitrogen for 5 min, and place it in a 25°C incubator for dark cultivation to induce reversible hydrogenase. After 20 hours of dark induction to the algae solution, CCCP was added to a concentration of 15 μM before light, and the pH value was adjusted to 8.2 with sodium bicarbonate solution. The system stirs the algae liquid at a medium light intensity of 9000LX and a stirring speed of 150rpm, so that the algae liquid in ...

Embodiment 3

[0046] The subcardiac flat algae are cultured with Kangweifang nutrient salts. After being cultivated to the late logarithmic growth period, they are centrifuged, collected by membrane filtration, or cultured at high density to a concentration of 6 million ce11s / mL of the hydrogen-producing algae liquid. The method for producing hydrogen by using the two-step method of flat algae to photolyze water is shown in Figure 2. Take a stirred-type photohydrogen production reactor with a volume of 500 mL, fill it with algae liquid, seal the bottle mouth, replace the air with nitrogen for 5 min, and place it in a 25°C incubator for dark cultivation to induce reversible hydrogenase. After 20 hours of dark induction, CCCP was added to the concentration of 7.5 μM before light, and the pH value was adjusted to 8.2 with sodium bicarbonate solution. The system stirs the algae liquid at a medium light intensity of 9000LX and a stirring speed of 150rpm, so that the algae liquid in the photoreac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com