Bimetallic modified nano-composite blanket and processing method thereof

A nano-composite, metal modification technology, applied in blankets, sheets, textiles and papermaking, etc., can solve the problems of complex metal functionalization process, hard hand feeling of polypropylene fiber blankets, complicated double-sided setting process, etc., to achieve good hand feel, antibacterial Excellent performance and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

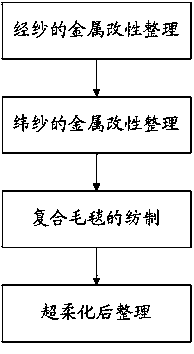

Method used

Image

Examples

example 1

[0031] DTY250D190F polypropylene superfine fiber is used as the fiber raw material, the warp yarn spun is Z twist 50, the yarn count is 40S, 2.5 inches of high-purity Ag is used as the sputtering target, and high-purity argon is used as the reaction gas, and the gas pressure is 2.5Pa Under certain conditions, the reaction power is 50W, and the reaction takes 200 seconds; 35S PBT high-elastic yarn is used as the weft yarn, 3.5-inch high-purity Ti is used as the sputtering target, and high-purity argon is used as the reaction gas, and the gas pressure is 1.5Pa Under certain conditions, the reaction power is 40W, and the reaction time is 150 seconds; through warping, weaving, slitting, white billet ironing, white billet shaping, printing, pre-baking, high temperature, high pressure dyeing, washing, and flower billet shaping, etc. At the same time, it is supplemented by double-sided shaping technology to form a functional double-sided super soft polypropylene blanket.

example 2

[0033] DTY250D195F polypropylene microfiber is used as the fiber raw material, the warp yarn spun is S twist 40, the yarn count is 40S, 2.5 inches of high-purity Ag is used as the sputtering target, high-purity argon is used as the reaction gas, and the gas pressure is 3 Pa Under certain conditions, the reaction power is 50W, and the reaction is 100 seconds; 40S PBT high-elastic yarn is used as the weft yarn, 3.5 inches of high-purity Ti is used as the sputtering target, and high-purity argon is used as the reaction gas, and the gas pressure is 0.5Pa Under certain conditions, the reaction power is 50W, and the reaction time is 100 seconds; through warping, weaving, slitting, white billet ironing, white billet shaping, printing, pre-baking, high temperature, high pressure dyeing, washing, and flower billet shaping, etc. At the same time, it is supplemented by double-sided shaping technology to form a functional double-sided super soft polypropylene blanket.

example 3

[0035] DTY250D192F polypropylene superfine fiber is used as the fiber raw material, the warp yarn spun is S twist 30, the yarn count is 35S, 2.5 inches of high-purity Ag is used as the sputtering target, high-purity argon is used as the reaction gas, and the gas pressure is 0.5 Pa Under certain conditions, the reaction power is 80W, and the reaction is 80 seconds; 35S PBT high-elastic yarn is used as the weft yarn, 3.5-inch high-purity Ti is used as the sputtering target, and high-purity argon is used as the reaction gas, and the gas pressure is 1.0Pa Under certain conditions, the reaction power is 30W, and the reaction time is 200 seconds; through warping, weaving, slitting, white billet ironing, white billet shaping, printing, pre-baking, high temperature, high pressure dyeing, washing, and flower billet shaping, etc. At the same time, it is supplemented by double-sided shaping technology to form a functional double-sided super soft polypropylene blanket.

[0036]In summary,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com