Diesel engine speed control device

A speed control device, diesel engine technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve the problems of large changes in diesel engine speed and torque, waste of fuel, inaccurate fuel injection, etc., to achieve economical performance, economical and practical , The emission performance is economical and practical, and the effect of saving maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

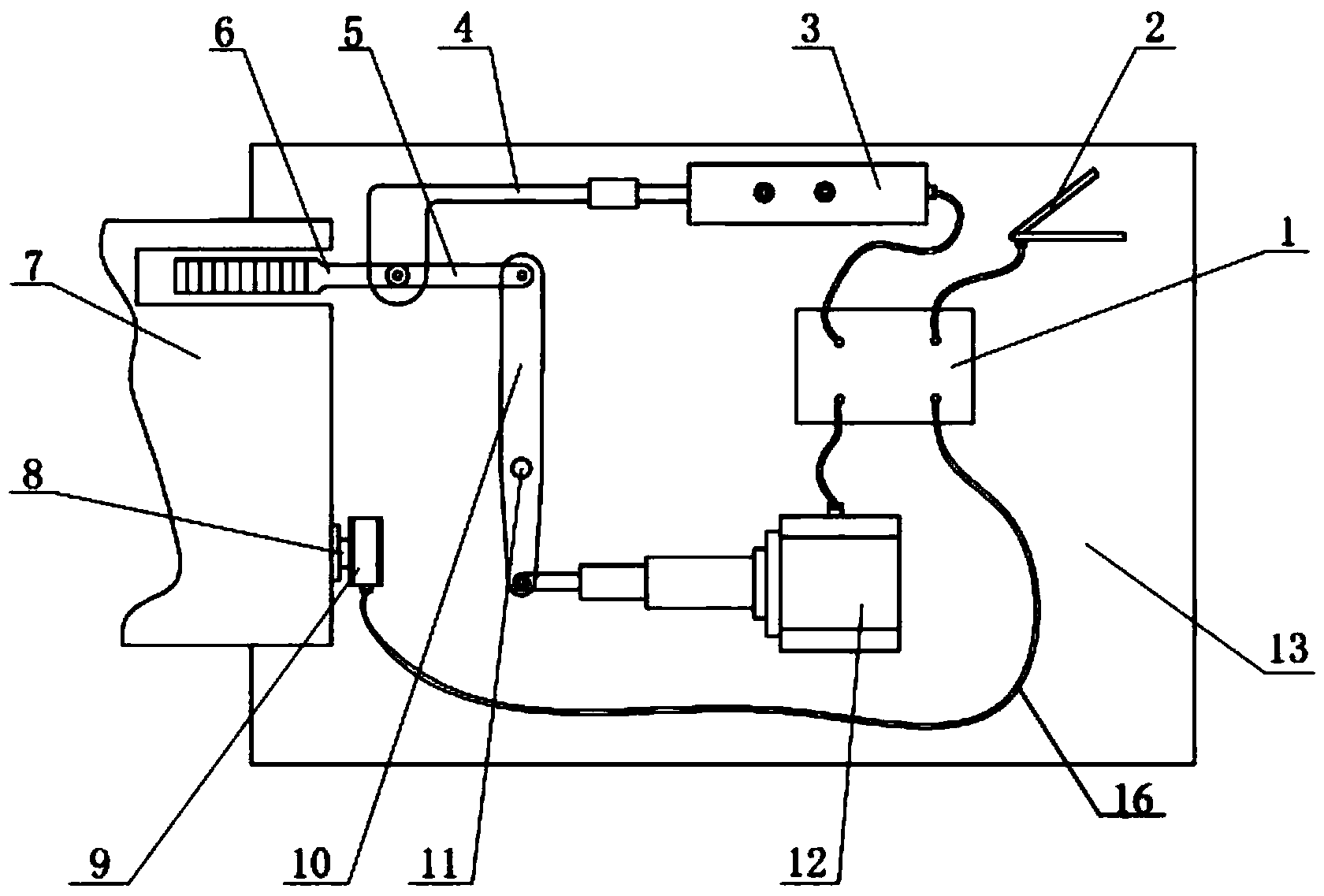

[0030] like figure 1 and figure 2 As shown, the present invention provides a diesel engine speed regulating device, comprising:

[0031] The casing includes an outer casing 13 and a front cover for closing the outer casing 13 .

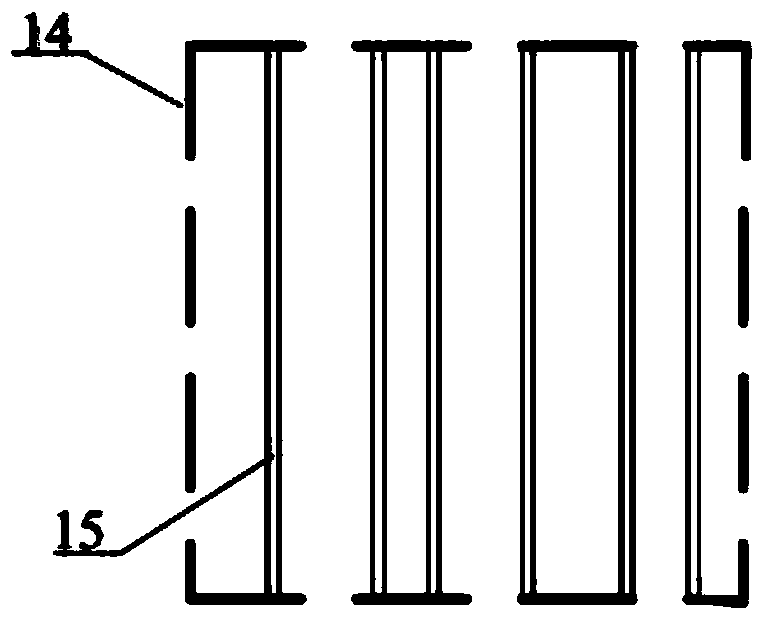

[0032] The inner casing 14 is arranged on the front cover and is closed by the front cover. The inner casing 14 is a breathable mesh casing, and a plurality of test lines 15 are arranged in the inner casing 14 .

[0033] The microprocessor 1 is arranged in the housing 13; in one embodiment, the microprocessor 1 is a single-chip microcomputer control board.

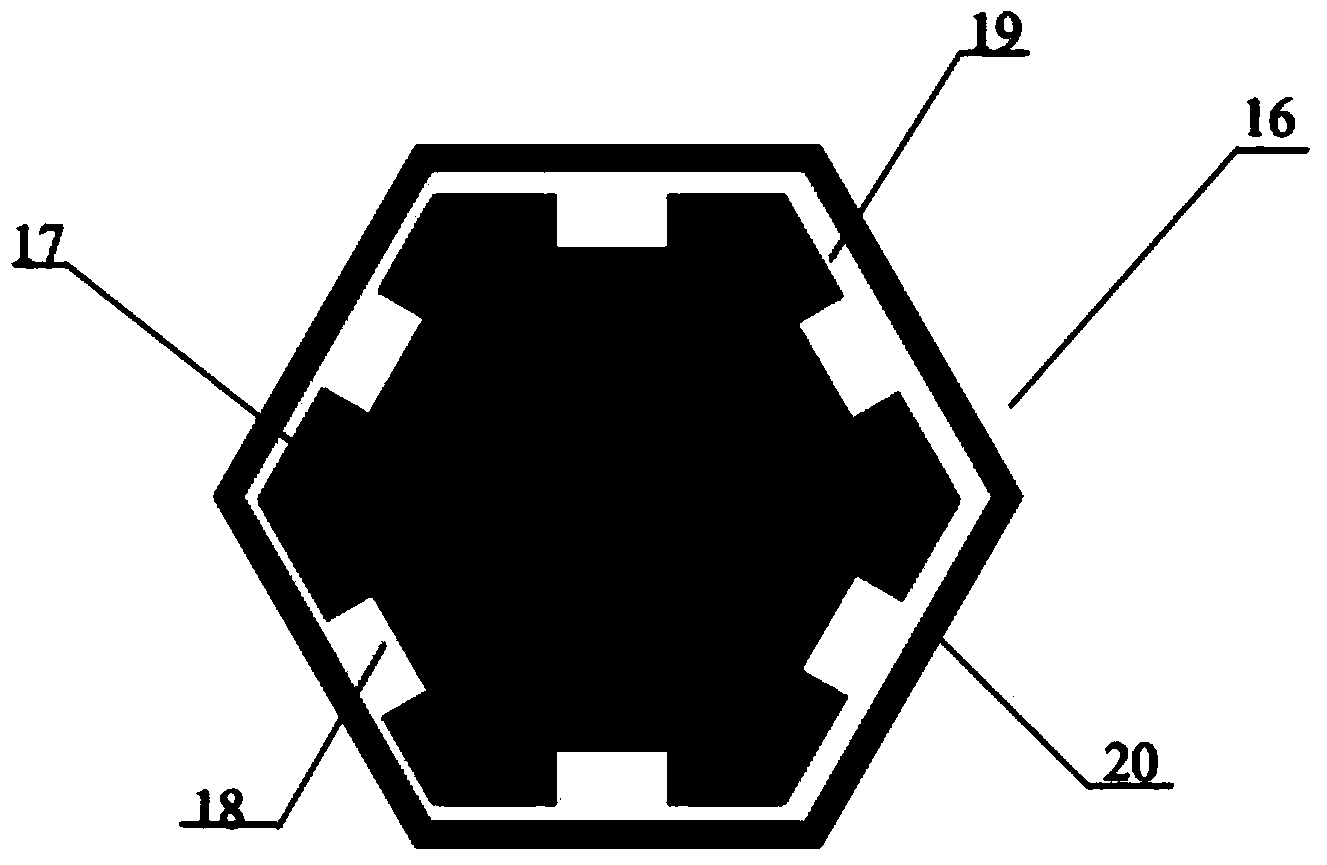

[0034] A linear drive mechanism 12 is arranged in the housing, and the linear drive mechanism 12 is connected to the microprocessor 1 through a wire 16; in one embodiment, the linear drive me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com