Vacuum coating gas source quick-changing device

A technology of vacuum coating and gas source, applied in the installation device of container structure, fixed capacity gas storage tank, gas/liquid distribution and storage, etc., can solve the problems of difficulty, high cost, inconvenient replacement of gas source, etc., and achieve deformation Uniform, improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

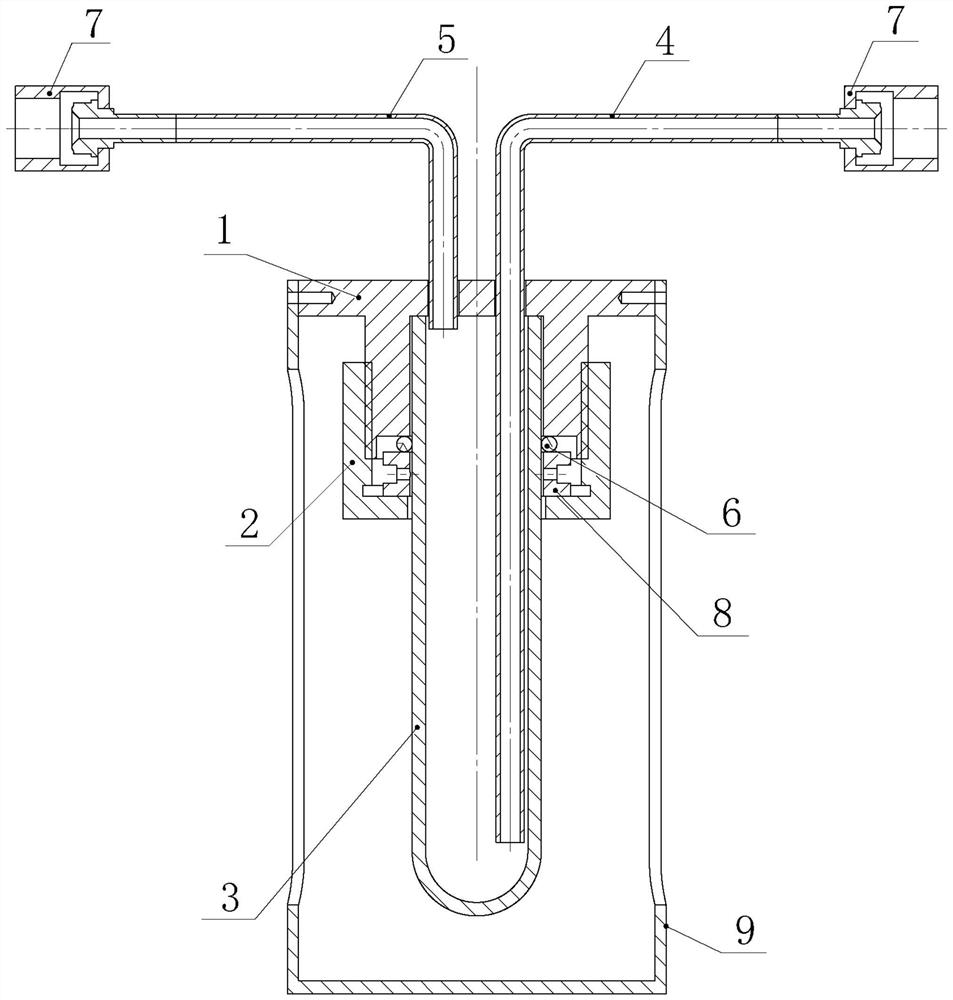

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] like figure 1 As shown, the vacuum coating gas source quick change device of the present invention includes a support 1 , a compression nut 2 , a gas storage bottle 3 , an air inlet pipe 4 and an air outlet pipe 5 . The support 1 is made of metal material to facilitate sealing and welding with the air inlet pipe 4 and the air outlet pipe 5. For example, the support 1 is made of stainless steel. The support 1 is cylindrical or includes a cylindrical part, and a circular counterbore is arranged at the center of one bottom surface of the cylinder, figure 1 Among them, the surface directly in contact with the sealing ring 6 is the bottom surface of the support 1, and the center line of the cylinder coincides with the center line of the circular counterbore. For example, the support 1 is in the shape of π or Π on the section passing through the center line of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com