Hydraulic system for recycling rotary braking energy and device

A hydraulic system and braking energy technology, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, servo motor components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

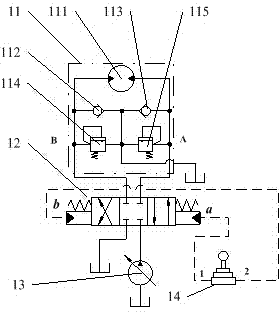

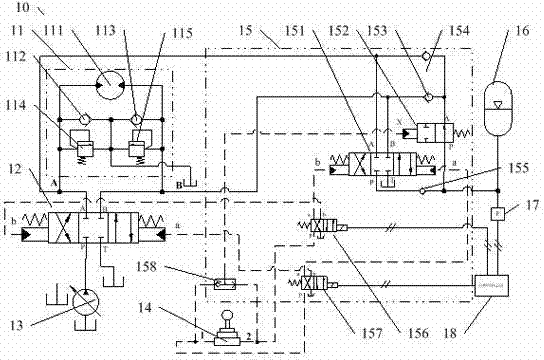

[0020] The hydraulic system 10 of the present invention with recovery of slewing braking energy is as figure 2 As shown, the oil supply ports A and B of the first hydraulically controlled three-position four-way reversing valve 12 are respectively provided with oil supply pipelines connected to the accumulator 16 at the same time, and the first oil supply pipelines are respectively set in each oil supply pipeline. One-way valve 154 and second one-way valve 153 are used to ensure oil supply port A or B to supply oil to the accumulator 16 in one direction, and a hydraulically controlled two-position two-way reversing valve is arranged in the oil supply pipeline of the accumulator 16. The valve 152 is used to switch the oil supply pipeline; the oil supply ports A and B of the first liquid press three-position four-way reversing valve 12 are respectively provided with the second hydraulic control three-position four-way reversing valve 151 The P port of the second hydraulically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com