Sports ground primer and preparation method thereof

A primer and sports field technology, applied in the field of coatings, can solve the problem of easy deformation of the bottom layer, achieve the effect of long-term color change, ensure mechanical strength, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

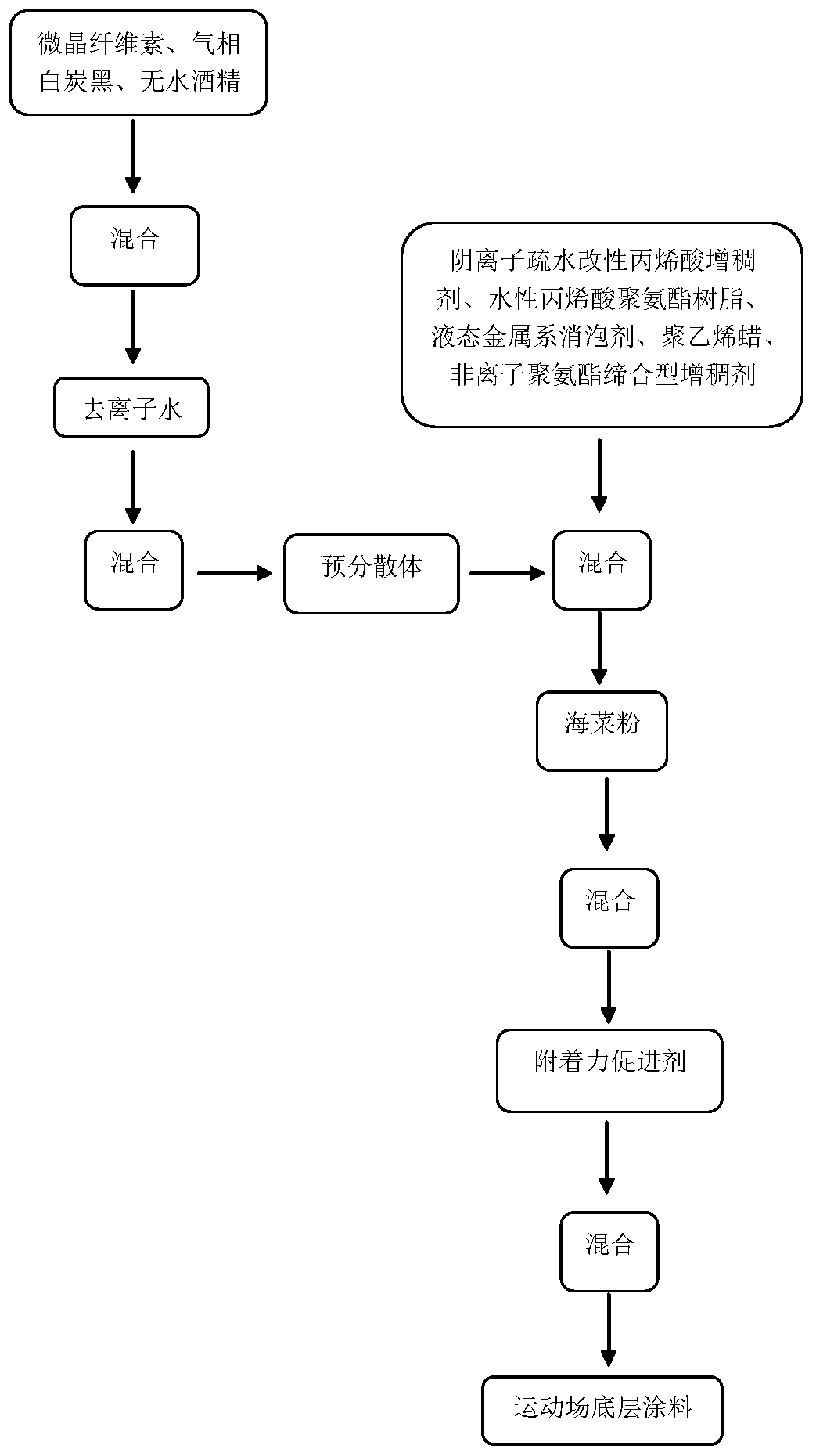

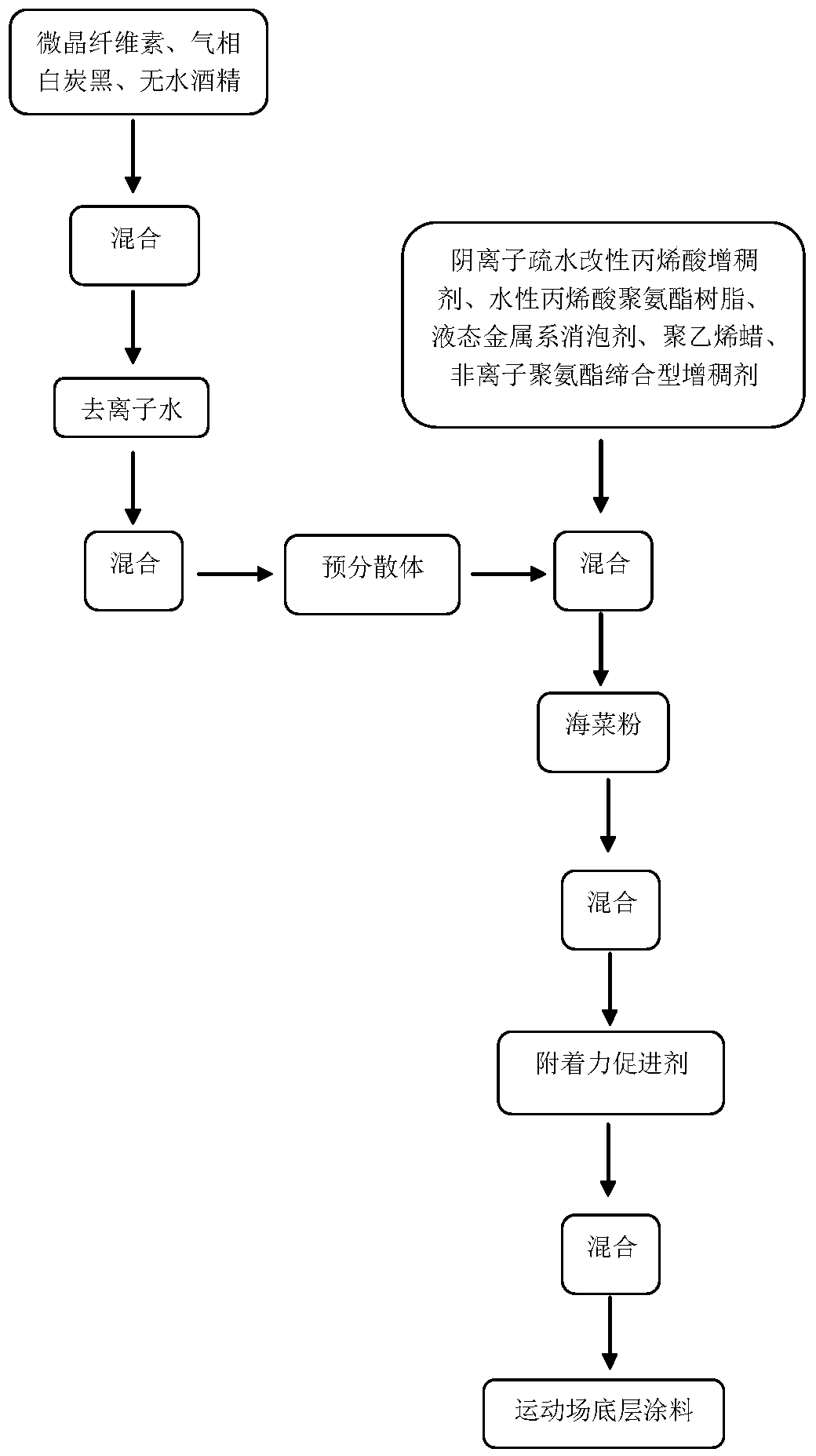

Method used

Image

Examples

Embodiment 1

[0035] 1. Put 90g of microcrystalline cellulose, 32g of fumed silica, and 370g of absolute alcohol into the container and stir evenly;

[0036] 2. Add 19 g of deionized water to the mixture obtained in step 1, and stir evenly to obtain a pre-dispersion;

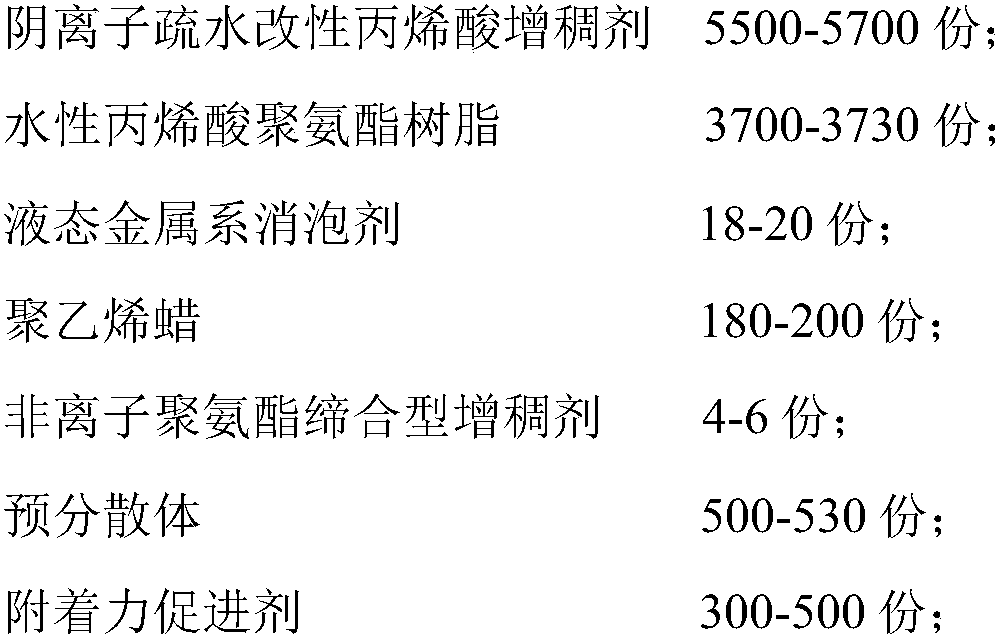

[0037] 3. Add 5500g of anionic hydrophobic modified acrylic thickener, 3730g of water-based acrylic polyurethane resin, 20g of liquid metal defoamer, 200g of polyethylene wax, and 6g of nonionic polyurethane associative thickener into the container and stir evenly;

[0038] 4. Add the pre-dispersion obtained in step 2 to the mixture obtained in step 3, and stir thoroughly;

[0039] 5. Add 7g of seaweed powder to the mixture obtained in step 4, and mix well;

[0040] 6. Add 300g adhesion promoter to the mixture obtained in step 5, and mix evenly to prepare the playground primer.

Embodiment 2

[0042] 1. Put 105g of microcrystalline cellulose, 36g of fumed silica, and 360g of absolute alcohol into the container and stir evenly;

[0043] 2. Add 18g of deionized water to the mixture obtained in step 1, and stir evenly to obtain a pre-dispersion;

[0044] 3. Add 5700g of anionic hydrophobically modified acrylic thickener, 3700g of water-based acrylic polyurethane resin, 18g of liquid metal defoamer, 180g of polyethylene wax, and 4g of nonionic polyurethane associative thickener into the container and stir evenly;

[0045] 4. Add the pre-dispersion obtained in step 2 to the mixture obtained in step 3, and stir thoroughly;

[0046] 5. Add 10g of seaweed powder to the mixture obtained in step 4, and mix well;

[0047] 6. Add 500g of adhesion promoter to the mixture obtained in step 5, and mix well.

Embodiment 3

[0049] 1. Put 98g of microcrystalline cellulose, 33g of fumed silica, and 365g of absolute alcohol into the container and stir evenly;

[0050] 2. Add 19 g of deionized water to the mixture obtained in step 1, and stir evenly to obtain a pre-dispersion;

[0051] 3. Add 5600g of anionic hydrophobically modified acrylic thickener, 3715g of water-based acrylic polyurethane resin, 19g of liquid metal defoamer, 190g of polyethylene wax, and 5g of nonionic polyurethane associative thickener into the container and stir evenly;

[0052] 4. Add the pre-dispersion obtained in step 2 to the mixture obtained in step 3, and stir thoroughly;

[0053] 5. Add 8g of seaweed powder to the mixture obtained in step 4, and mix well;

[0054] 6. Add 400g of adhesion promoter to the mixture obtained in step 5, and mix well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com