Heat recovery control circuit for air conditioner

A control circuit and heat recovery technology, applied in the control input involving air characteristics, space heating and ventilation control input, heat recovery system, etc. problems, to achieve the effect of reducing equipment investment costs, solving long development cycles, and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

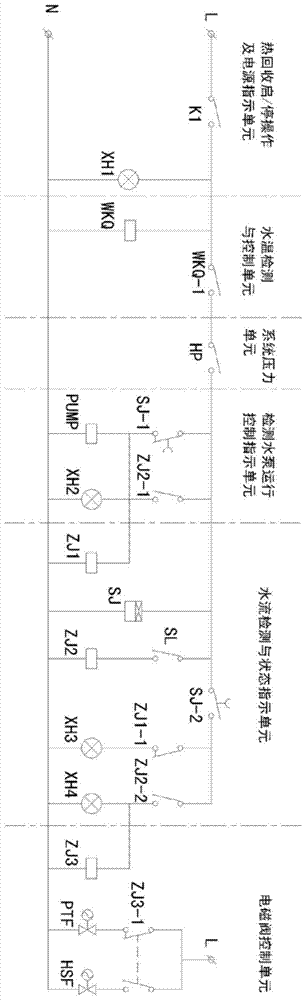

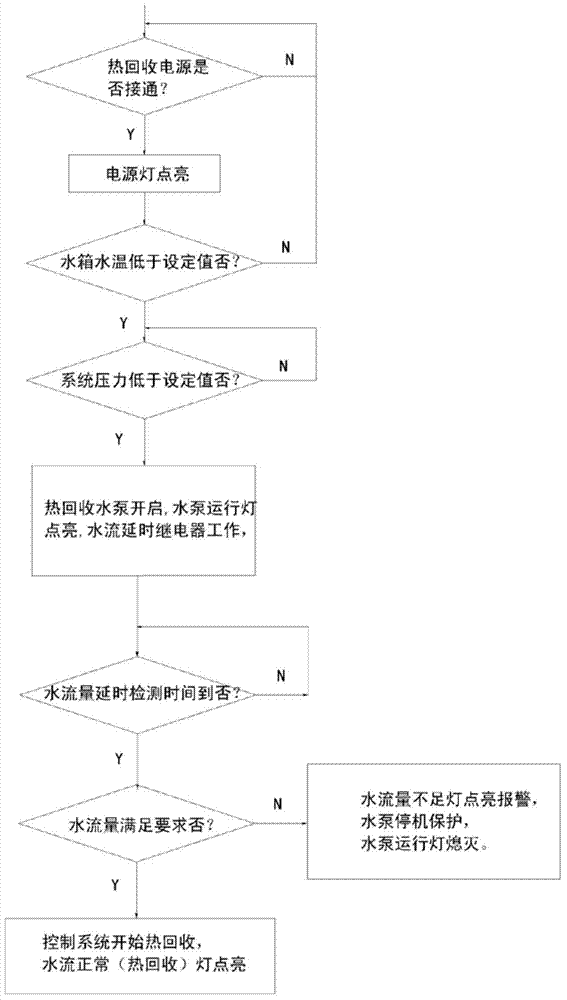

[0036] In this example, if figure 1 As shown, a heat recovery control circuit applied to an air conditioner includes a heat recovery start / stop operation and indication unit, a water temperature detection and control unit, an air conditioner system pressure detection unit, a water pump operation and indication unit, and a water flow detection and indication unit , Solenoid valve control unit.

[0037] The heat recovery start / stop operation and indication unit includes a single-pole switch K1 and a power-on indicator light XH1 to provide working power for the subsequent water temperature detection and control unit;

[0038] The input end of the unipolar switch K1 is connected to the live wire L of 220V AC, one end of the power indicator XH1 is connected to the outlet end of the unipolar switch K1, and the other end is connected to the neutral line N of 220V AC;

[0039] The water temperature detection and control unit includes the temperature controller WKQ and the normally op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com