Detection device and detection method for detecting air tightness of air-tight door of nuclear power plant by using constant pressure method

A detection device and air tightness testing technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problem of not being able to test the airtightness of the airtight door and affecting the accuracy of the measurement , inaccurate detection methods, etc., to achieve the effect of reducing the amount of testers and manual calculations, reducing gas leakage, and quantitatively calculating the airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

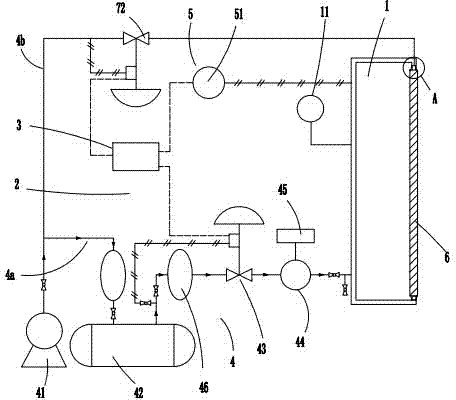

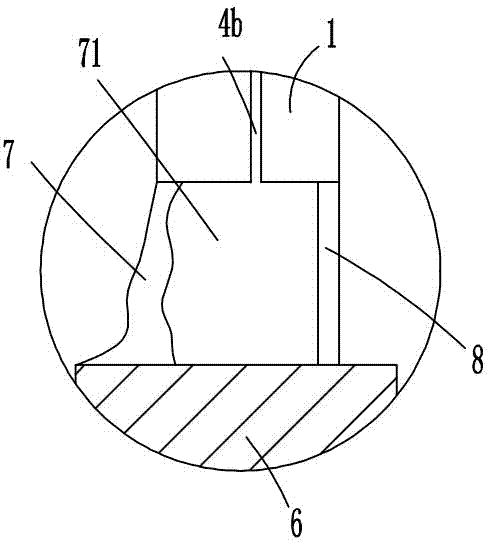

[0040] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] Figure 1 to Figure 2 Shown is the structural representation of the present invention.

[0042] The reference signs are: air tightness test box 1, U-shaped meter 11, test system 2, digital regulator 3, high-pressure air supply device 4, first pipeline 4a, second pipeline 4b, air compressor 41, Gas buffer tank 42, pneumatic regulating valve 43, gas mass flowmeter 44, flow totalizer 45, filter type pressure reducing valve 46, box state monitoring device 5, pressure transmitter 51, test piece 6, sealing ring 7. Inflatable cavity 71 , pressure control valve 72 , sealing ring 8 .

[0043] Such as Figure 1 to Figure 2 as shown,

[0044]A testing device for testing the airtightness of an airtight door in a nuclear power plant by the constant pressure method, including an airtightness test box 1 and a test system 2, the airtightness test bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com