Automatic cloth defect point detection and recognition device and method based on machine vision

A machine vision, automatic detection technology, applied in character and pattern recognition, instruments, computer parts and other directions, can solve the problems of high missed detection rate and false detection rate, low detection efficiency, visual fatigue and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

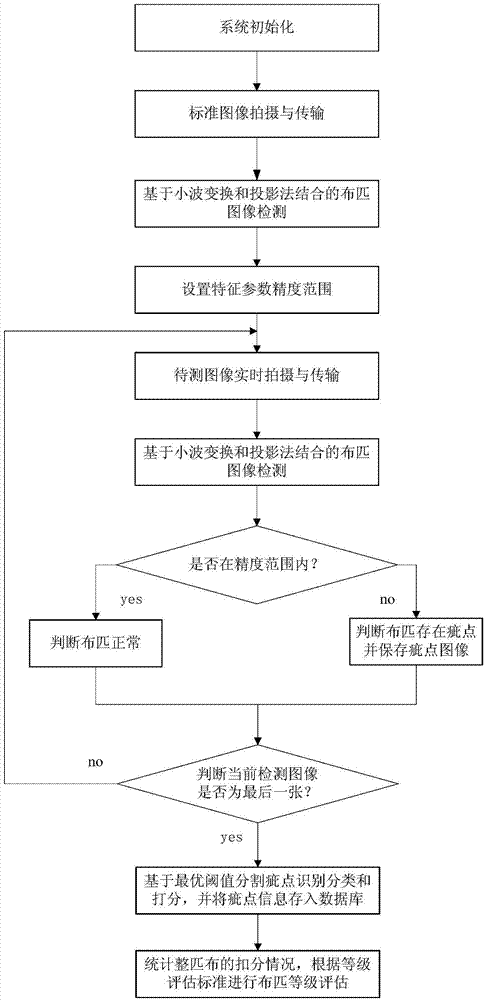

[0084] The present invention will be further described below in conjunction with the accompanying drawings.

[0085] Such as Figure 1-5 As shown, a machine vision-based automatic detection and recognition device for cloth defects includes a computer 1, a beam device 7, a high-power LED lamp 6, a camera 2, and a cloth 3, and the cloth 3 is arranged on a cloth winder 4 and a cloth guide roller 5, the camera 2 is fixed on the beam device 7, the camera 2 is connected with the computer 1 through a communication line, and the high-power LED lamp 6 is fixed on the beam device 7 and evenly distributed on the cloth 3 top.

[0086] A method for automatic detection and recognition of cloth defects based on machine vision, comprising the following steps:

[0087] Step (2a), using a camera to take a defect-free cloth image, and sending the acquired cloth image into the computer as a standard cloth image;

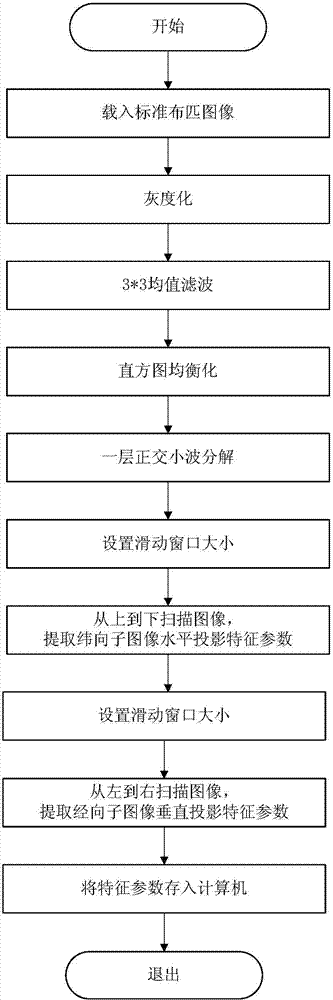

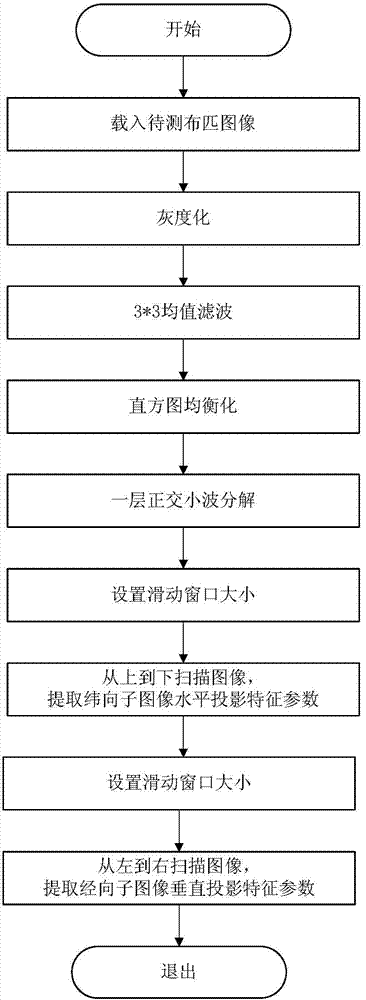

[0088] Step (2b), process the standard cloth image in step (2a) with a defect det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com