A method to determine the feasible solution of energy comprehensive dispatching in iron and steel enterprises

A feasible solution, enterprise technology, applied in special data processing applications, instruments, manufacturing computing systems, etc., can solve problems such as difficulty in obtaining feasible solutions for comprehensive energy scheduling in iron and steel enterprises, saving computing time and software and hardware resources, and improving diversity. The effect of features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

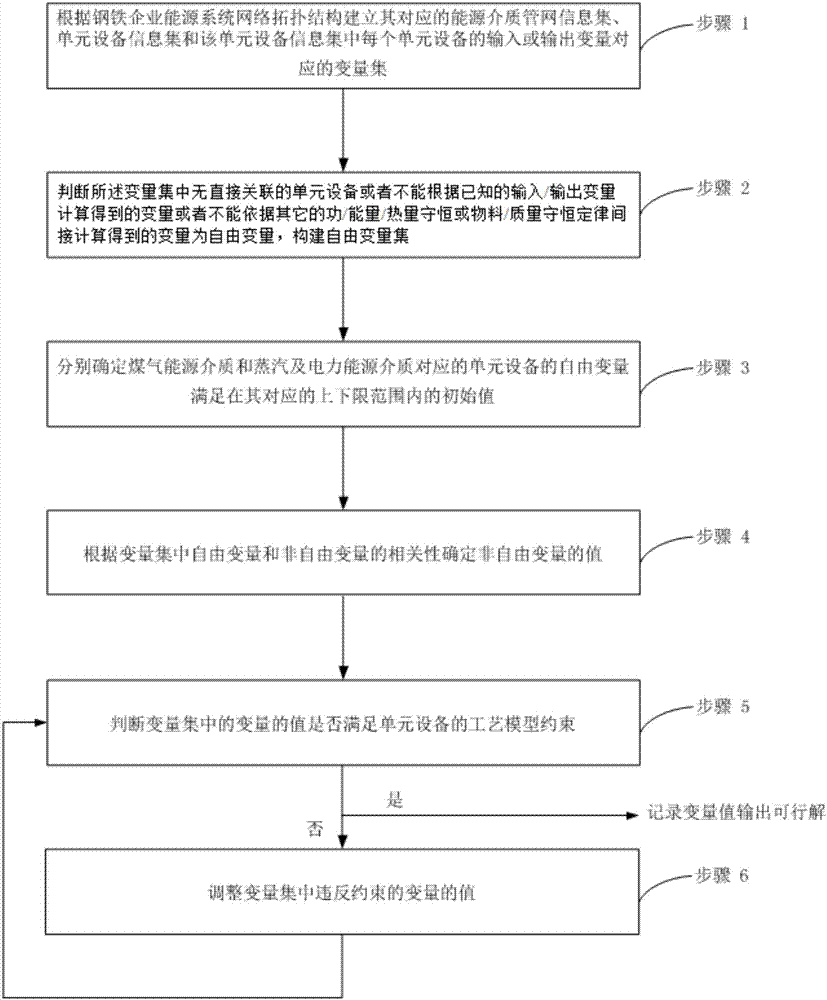

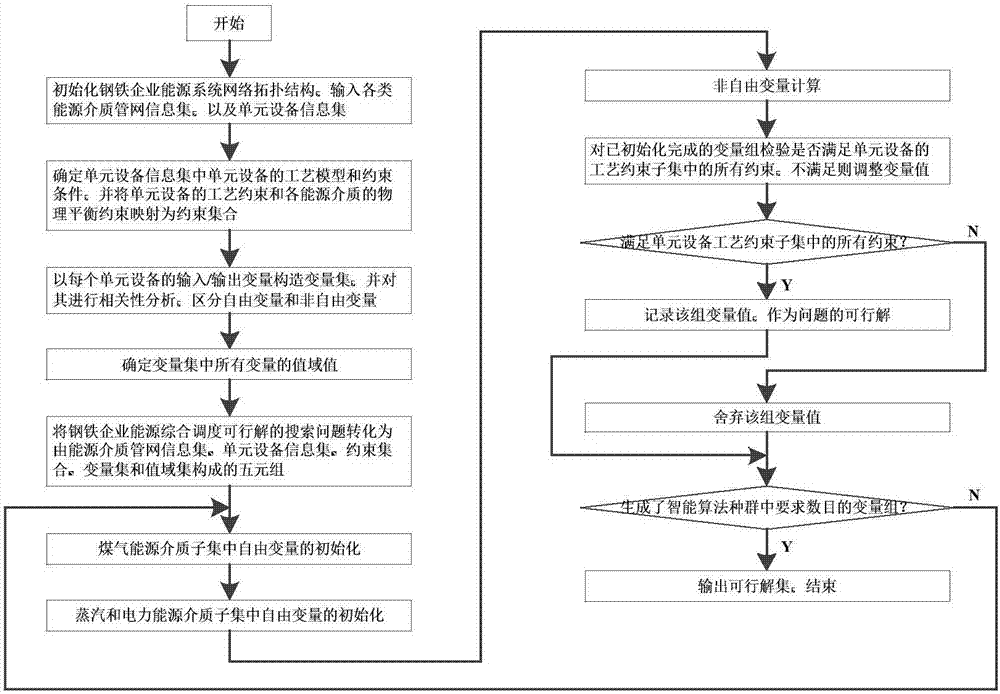

[0047] Such as figure 2 Shown is a detailed flowchart of a method for determining a feasible solution for comprehensive energy dispatching in a steel enterprise provided by an embodiment of the present invention. figure 2 It can be seen that the embodiment of the method for determining a feasible solution for the comprehensive energy dispatching of a steel enterprise provided by the present invention includes:

[0048] In the embodiment of the present invention, step 1 is the process of initializing the integrated energy dispatching problem of the iron and steel enterprise according to the network topology of the energy system of the iron and steel enterprise, and further includes:

[0049] Step 101: Establish an energy medium pipe network information set E={GAS, STM, ELE,...} and a unit equipment information set Ψ={MIX, PRE, HLD, EMI, BOI, TUR, VAL,...}.

[0050] GAS, STM and ELE are gas, steam and electric energy medium subsets respectively; MIX, PRE, HLD, EMI, BOI, TUR and VAL ar...

Embodiment 2

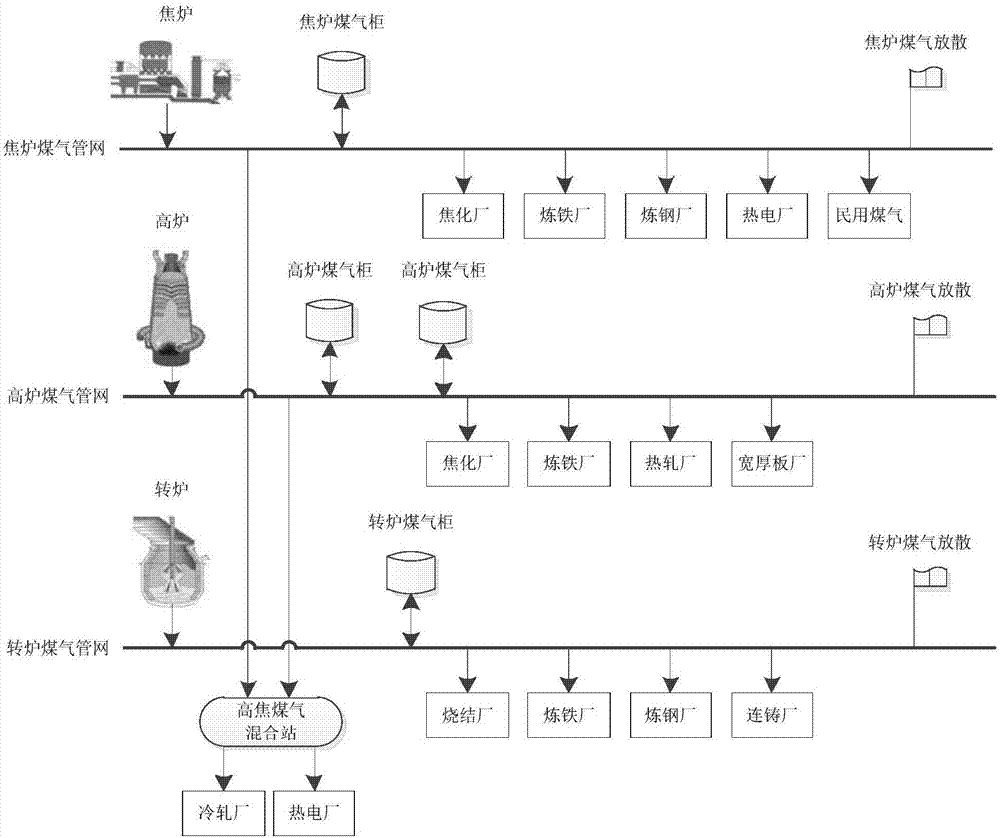

[0128] The second embodiment provided by the present invention is a specific application embodiment of a method for determining a feasible solution for comprehensive energy dispatching of a steel enterprise provided by the present invention, such as image 3 Shown is the topological structure diagram of the gas subsystem of a typical steel enterprise, Figure 4 It is the topological structure diagram of the steam and power subsystem of a typical steel enterprise. by image 3 It can be seen that the main by-product gases of iron and steel enterprises are blast furnace gas (BFG), coke oven gas (COG) and converter gas (LDG), which are produced by blast furnace, coke oven and converter respectively. The main lines of various gas media are equipped with corresponding gas tanks and dispersing towers, and the main production process users, such as ironworks, steel plants and wide and heavy plate plants, are also connected to different pipe networks. In addition to a single gas medium, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com