Quartz crystal resonator and its packaging process

A technology of quartz crystals and resonators, which is applied to electrical components, impedance networks, etc., can solve the problems of easy desoldering or virtual soldering in welding methods, inability to produce and process in large quantities, and degradation of stability performance, etc., to achieve enhanced stability and firmness , Reduce air leakage rate, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in detail below with reference to the drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

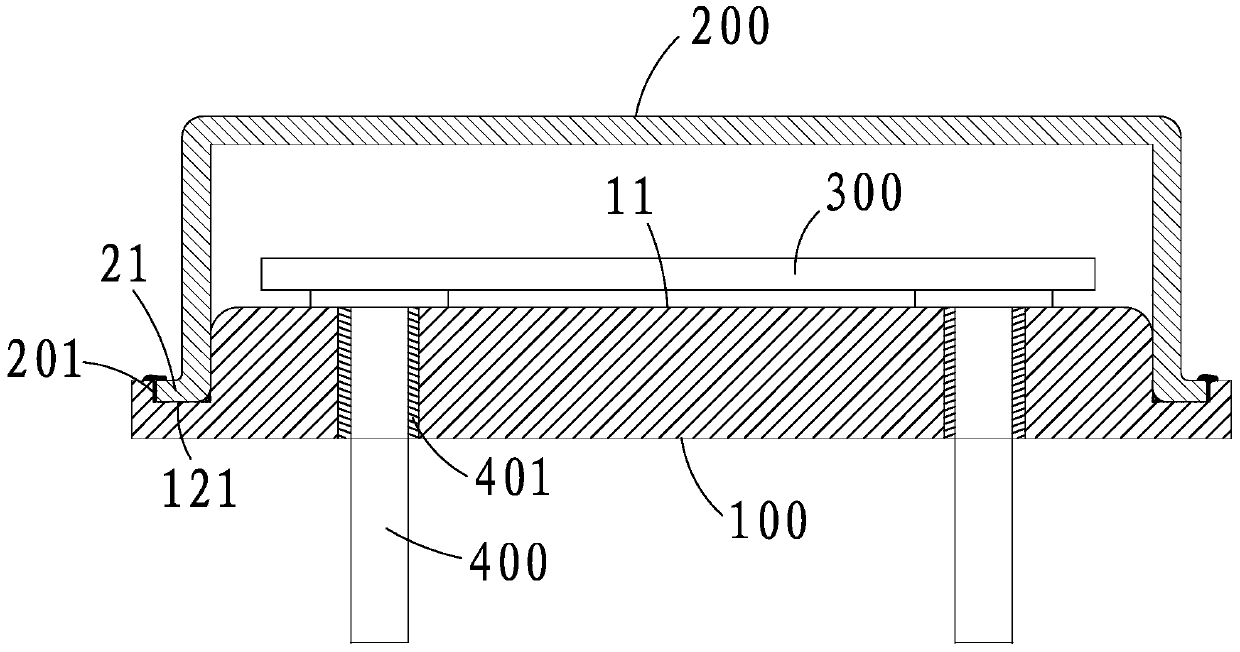

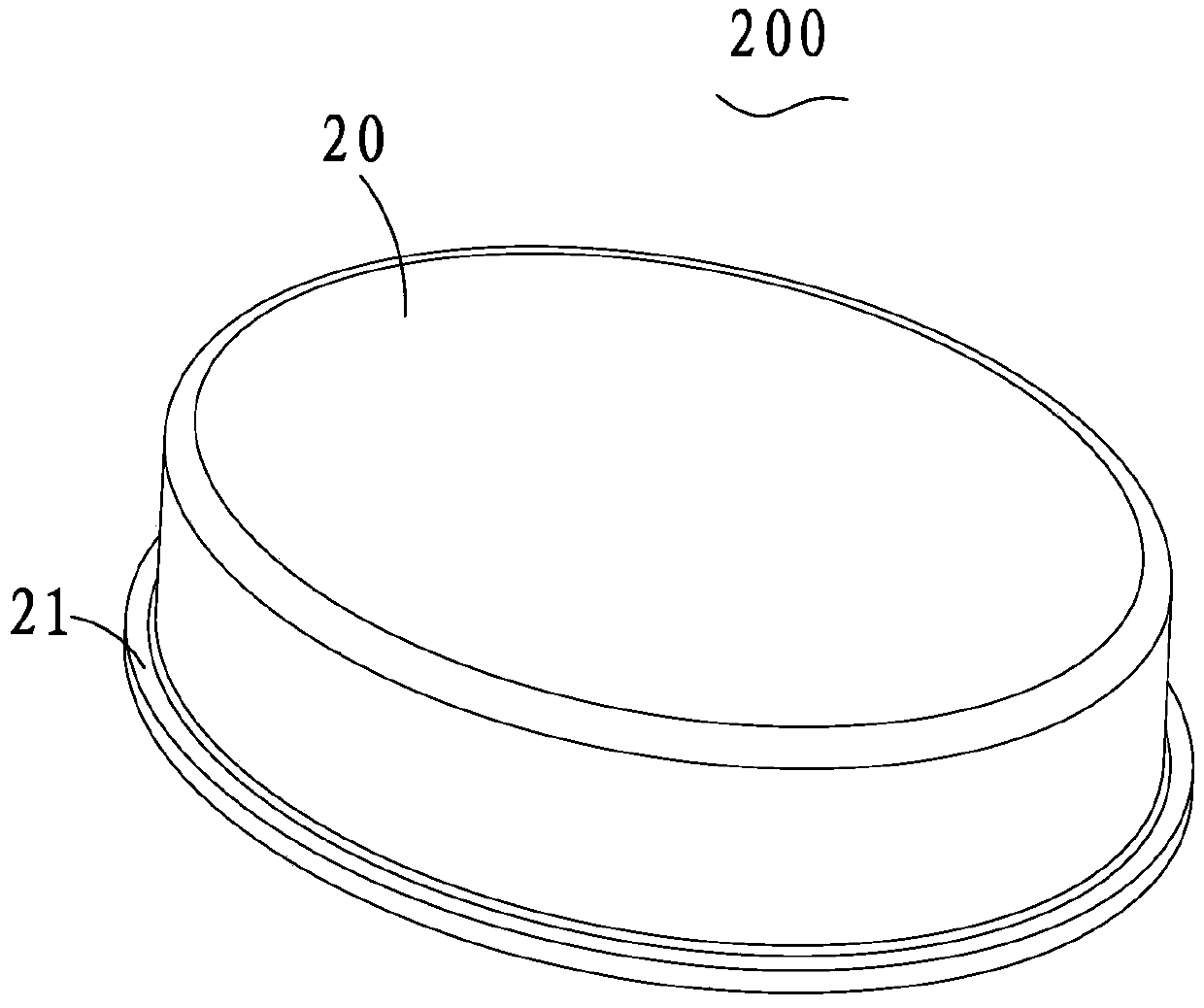

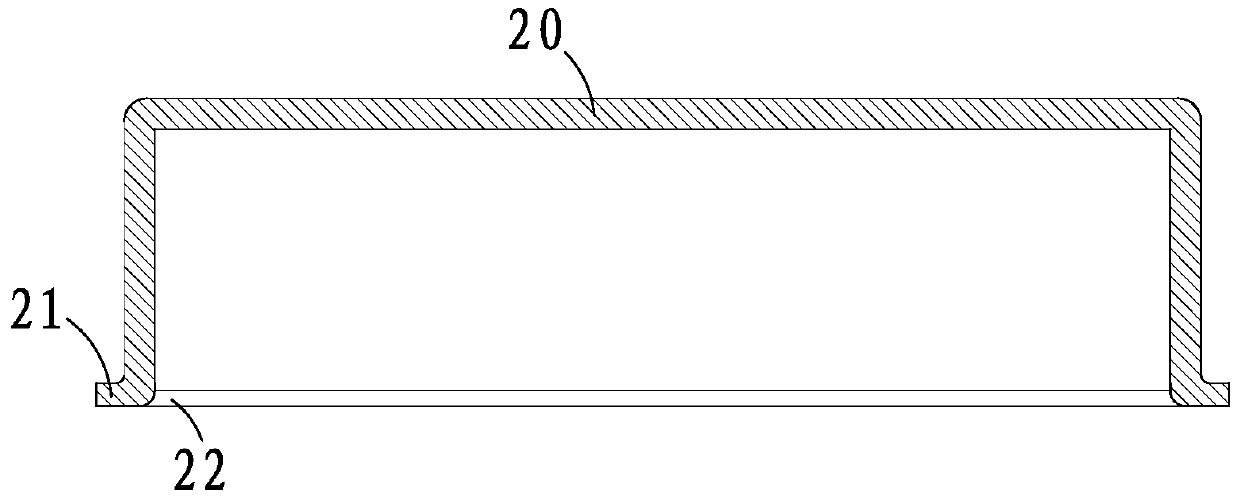

[0032] Reference Figure 1 to Figure 5 As shown, the present invention provides a quartz crystal resonator, including a shell, a chip 300 and pins 400, wherein the shell is composed of a bottom plate 100 and an upper shell 200, and the bottom plate 100 includes a substrate 10 and a protrusion formed by the substrate 10. A step surface 12 is formed on the outer side of the boss 11, and an annular groove 121 is formed on the step surface 12; the upper shell 200 includes a cover body 20 with a closed upper end and an open end at the lower end. The lower end of the cover body 20 is inserted into the annular recess In the groove 121, the gap between the inner surface of the annular groove 121 and the outer surface of the lower end of the cover 20 is seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com