Disk brake having a restoring device and a brake lining

A disc brake and brake lining technology, applied in the direction of brake type, axial brake, brake components, etc., can solve the problem of affecting the effect of the brake, unsuitable for the application of heavy trucks, etc., to avoid residual sliding wear The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the description of the drawings below, concepts such as up, down, left, right, front, rear, etc. are only for the exemplary illustrations selected in the corresponding drawings for disc brakes, brake linings, reset elements, etc. display and location. These concepts should be understood as non-limitative, ie these relationships may vary due to different operating conditions or mirror-symmetrical designs or the like.

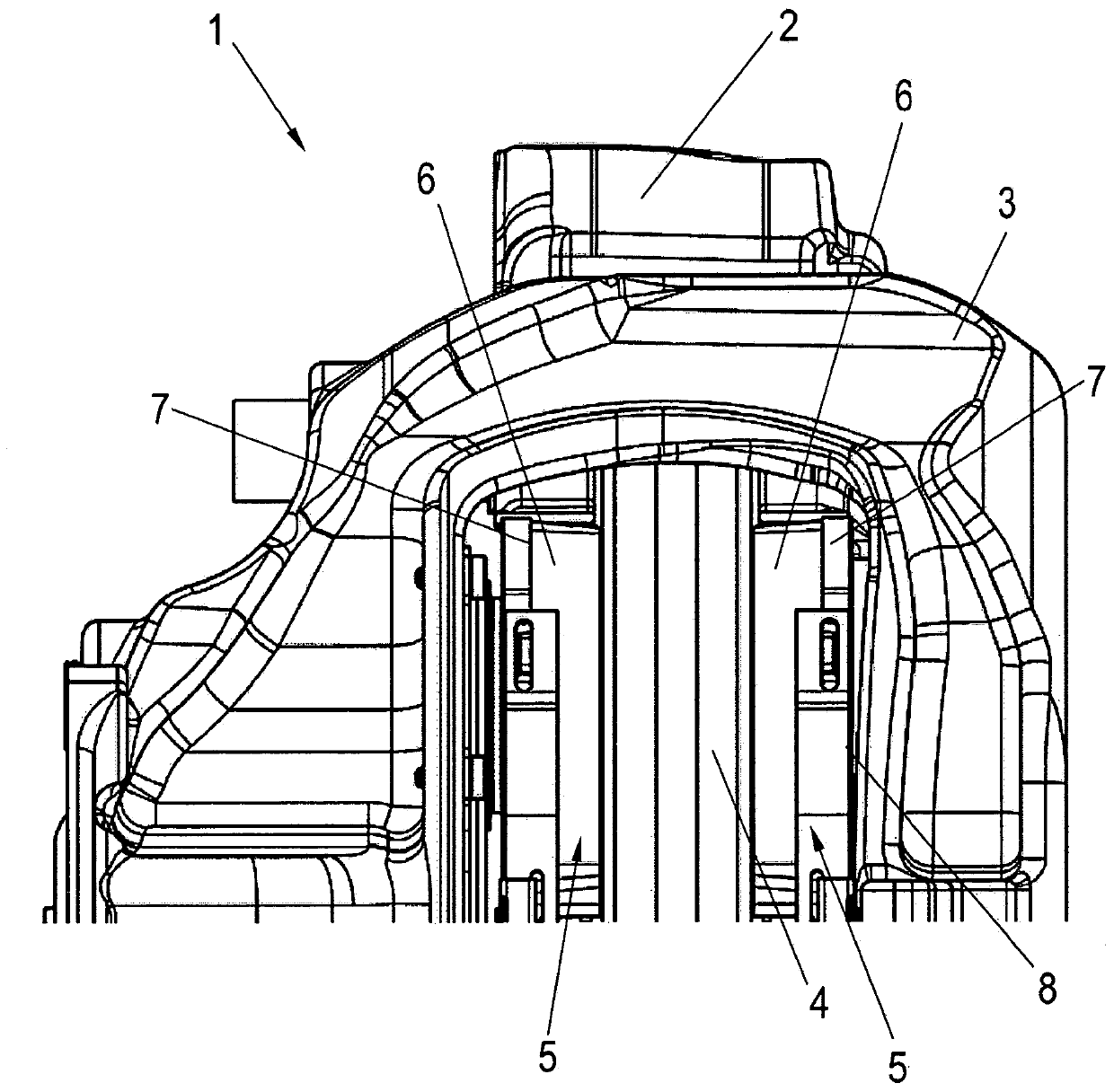

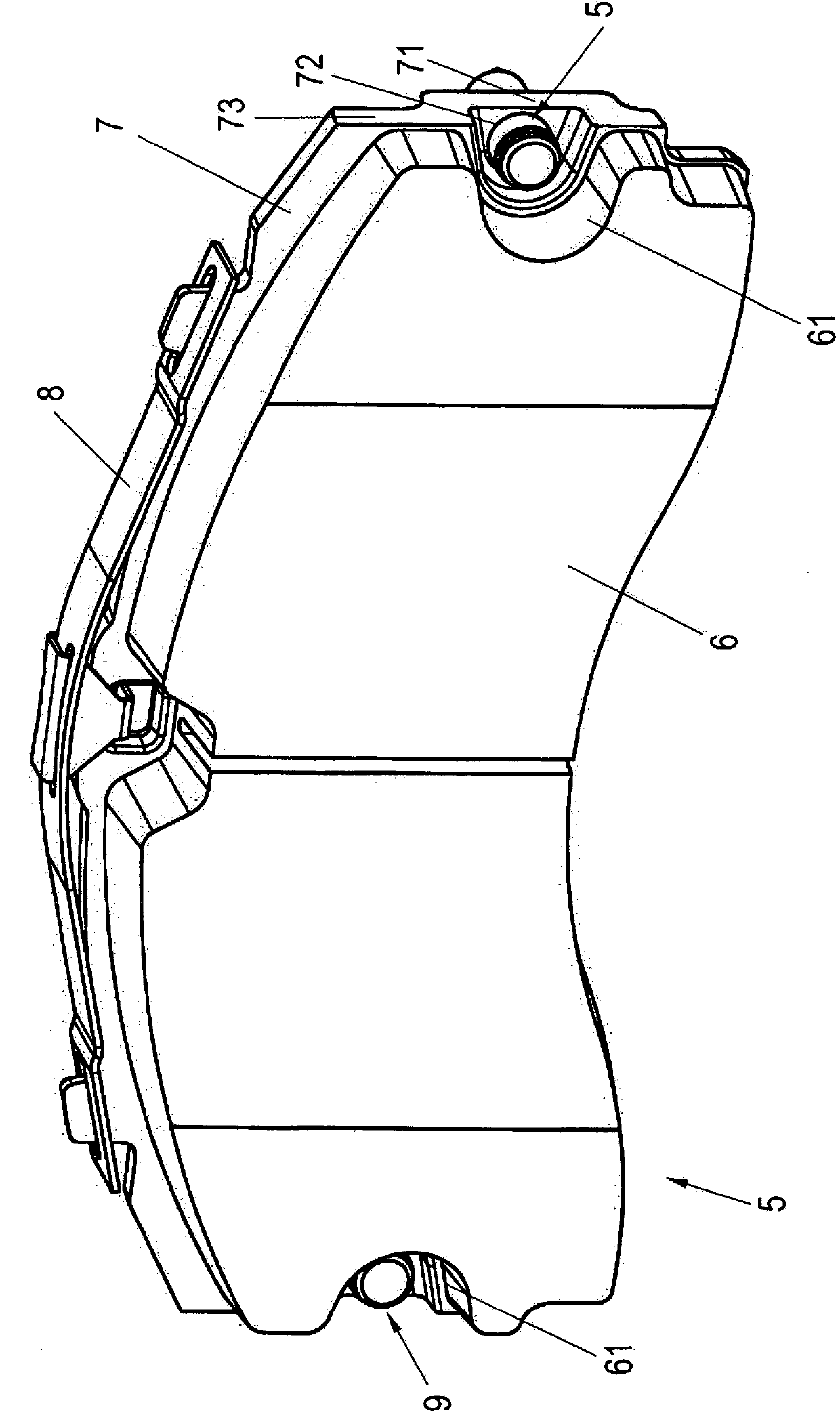

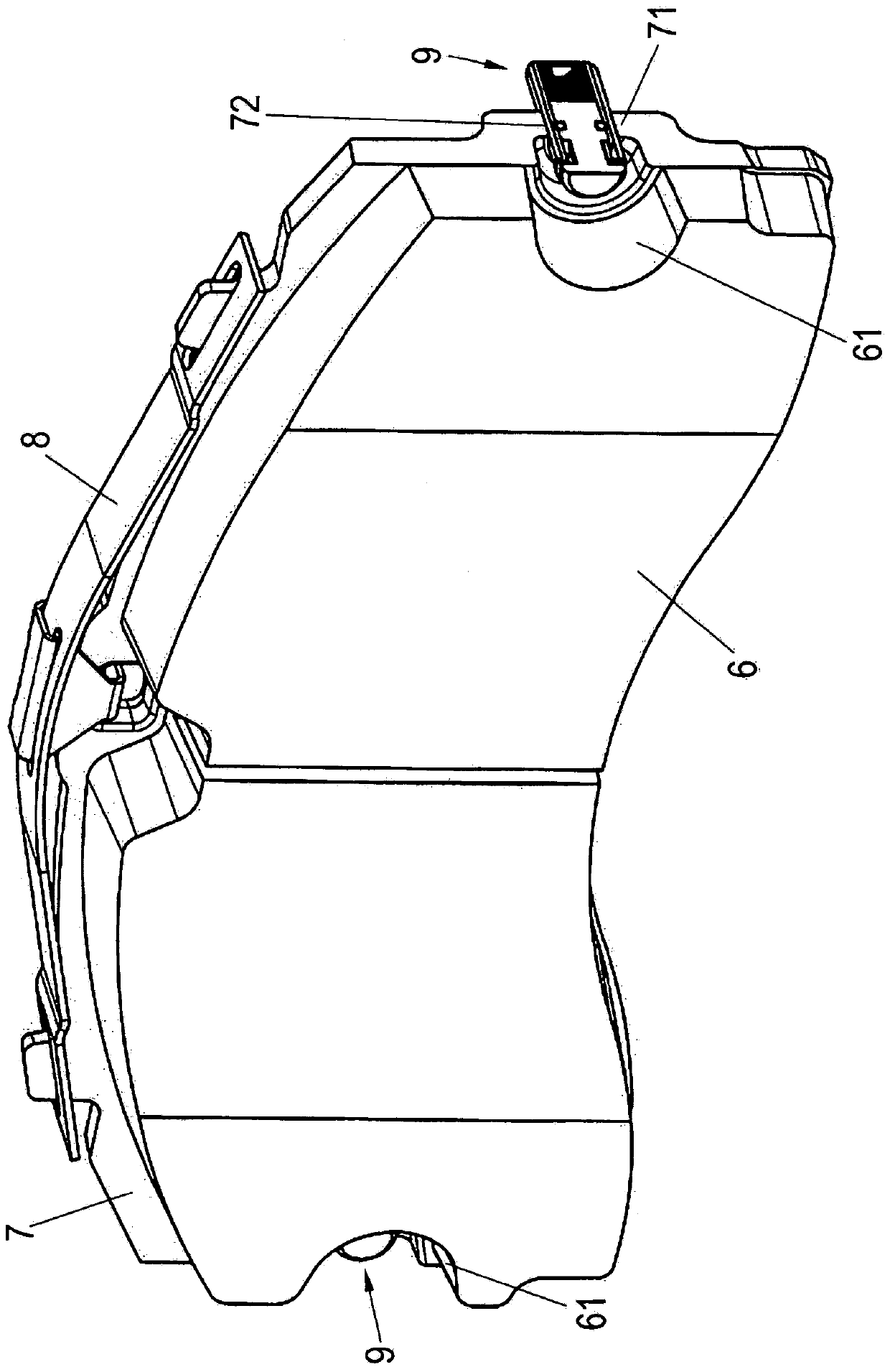

[0039] existfigure 1 In , the embodiment of the disc brake according to the invention is generally designated with the reference number 1 . The disc brake 1 has a pressing device, a brake caliper 3 spanning a brake disc 4 , which is preferably designed as a sliding caliper. In addition, preferably the disc brake 1 also has a lining wear compensation adjustment device for adjusting the air gap between the brake disc 4 and the brake linings 5 arranged on both sides of the brake disc 4, said The brake linings each have a lining carrier and at least one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com