Preparation process of wild ancient tree black tea

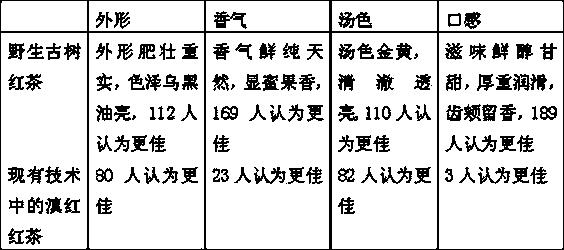

A production process, the technology of ancient tree black tea, which is applied in the field of production process of wild ancient tree black tea, to achieve the effect of better appearance, pure taste and rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0025] A kind of manufacturing technology of wild ancient tree black tea, it adopts more than 500 years of Yunnan Province Lincang Fengqing wild arbor ancient tea tree fresh leaves as raw materials, the preparation process comprises the following steps:

[0026] (1) Picking of fresh leaves: one day after the rainy day in April, when picking, the fresh leaves are dry leaves, and the picking time is 22:00 at night;

[0027] (2) Withering: use hot air to wither, at a temperature of 45°C, with a leaf thickness of 19cm, and wither for 3 hours; after withering, the water loss rate of fresh leaves at this time is 40%;

[0028] (3) Kneading: No pressure is applied during the kneading process, and the kneading time is 55 minutes. After kneading, the strip formation rate is 93%, and the cell destruction rate is 83%;

[0029] (4) Fermentation: The thickness of the spread leaves is 10cm, and the temperature is 35°C for 3 hours;

[0030] (5) Drying: put the fermented tea evenly on the wat...

preparation Embodiment 2

[0032] A kind of manufacturing technology of wild ancient tree black tea, it adopts the fresh leaves of wild arbor ancient tea tree in Changning, Baoshan, Yunnan Province more than 500 years old as raw material, and the preparation technology comprises the following steps:

[0033] (1) Picking of fresh leaves: 2 days after the rainy day in April, when picking, the fresh leaves are dry leaves, and the picking time is 03:00 at night;

[0034] (2) Withering: Put the picked fresh leaves of ancient trees in the sun for 6 hours, and the thickness of the spread leaves is 15cm; after withering, the water loss rate of fresh leaves is 41% at this time;

[0035] (3) Kneading: No pressure is applied during the kneading process, and the kneading time is 50 minutes. After kneading, the strip forming rate is 90% and the cell destruction rate is 81%;

[0036] (4) Fermentation: The thickness of the spread leaves is 8cm, and the temperature is 40°C for 2 hours;

[0037] (5) Drying: put the fer...

preparation Embodiment 3

[0039] A kind of manufacturing technology of wild ancient tree black tea, it adopts the fresh leaves of wild arbor ancient tea tree in Changning, Baoshan, Yunnan Province more than 500 years old as raw material, and the preparation technology comprises the following steps:

[0040] (1) Picking of fresh leaves: 3 days after the rainy day in April, when picking, the fresh leaves are dry leaves, and the picking time is 01:30 at night;

[0041] (2) Withering: use hot air to wither, at a temperature of 50°C, with a leaf thickness of 18cm, and wither for 4 hours; after withering, the water loss rate of fresh leaves at this time is 44%;

[0042] (3) Kneading: No pressure is applied during the kneading process, and the kneading time is 60 minutes. After kneading, the strip formation rate is 95%, and the cell destruction rate is 85%;

[0043] (4) Fermentation: The thickness of the spread leaves is 12cm, and the temperature is 30°C for 4 hours;

[0044] (5) Drying: put the fermented te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com