Foaming agent tank

A technology of foaming agent and foaming gun, which is applied in the direction of spraying device, liquid spraying device, single handheld device, etc. It can solve the problems of inconvenient storage, potential safety hazards, waste, etc., and achieves simple structure, good sealing, and energy saving The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments with reference to the accompanying drawings, so as to better understand the present invention.

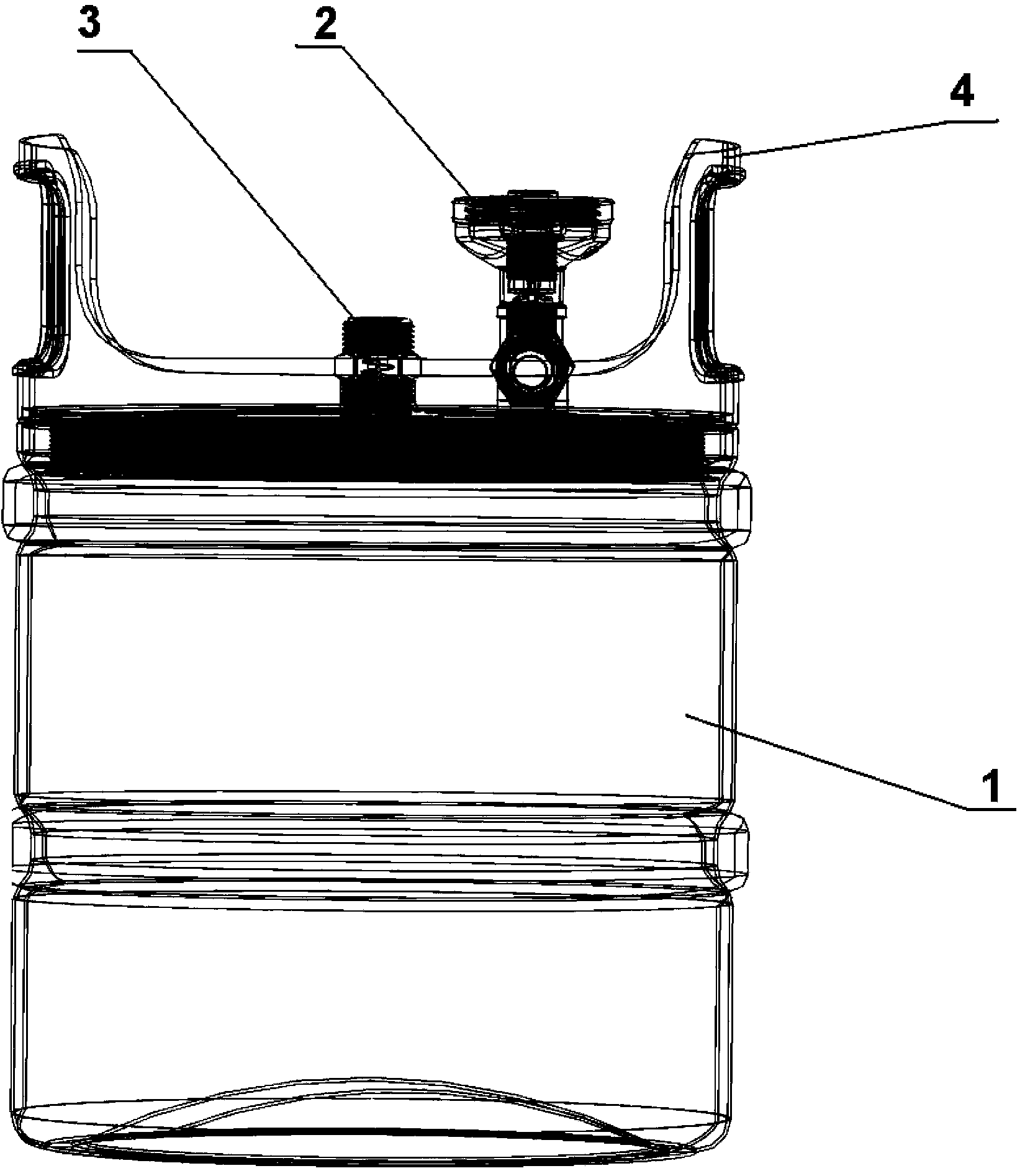

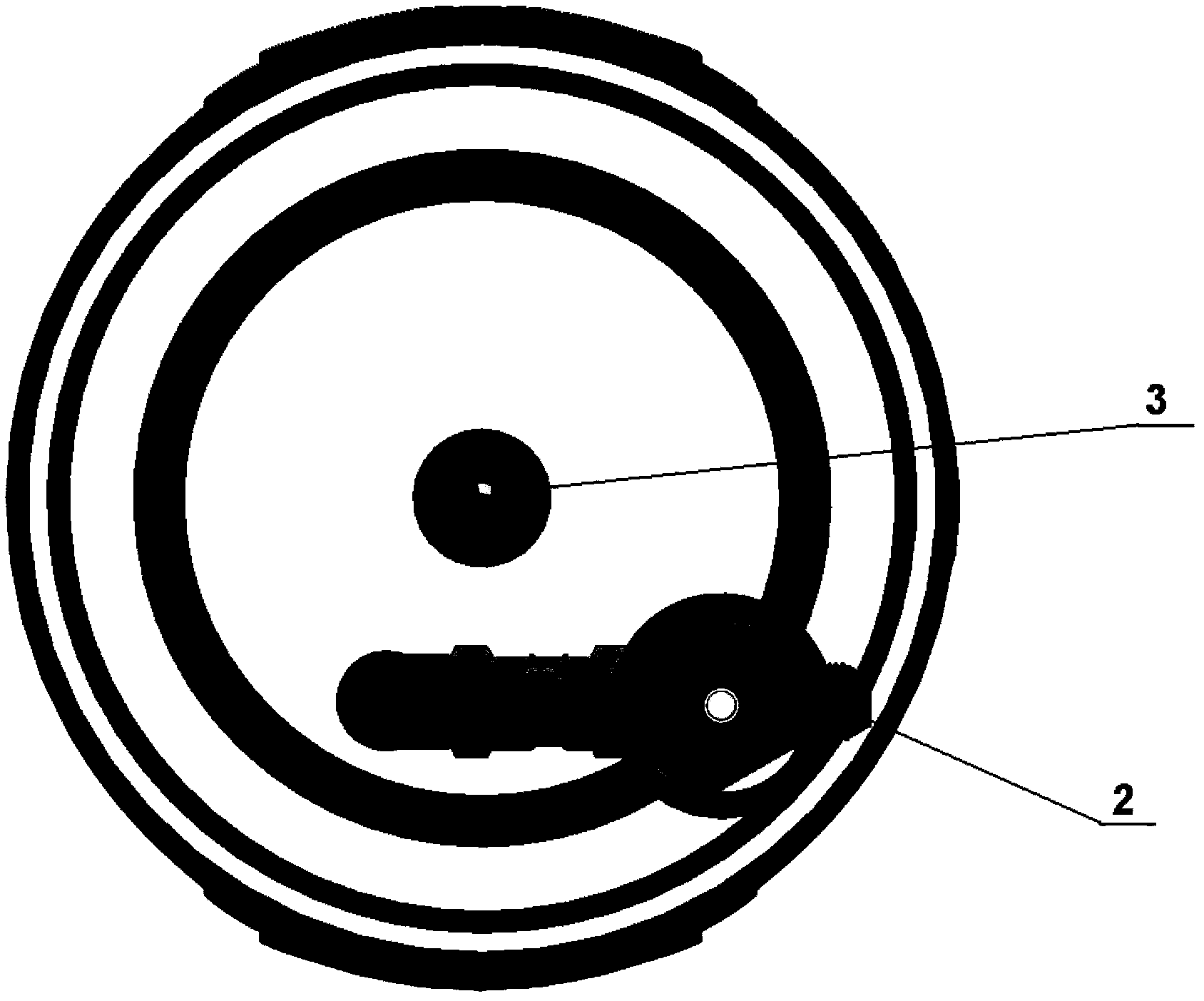

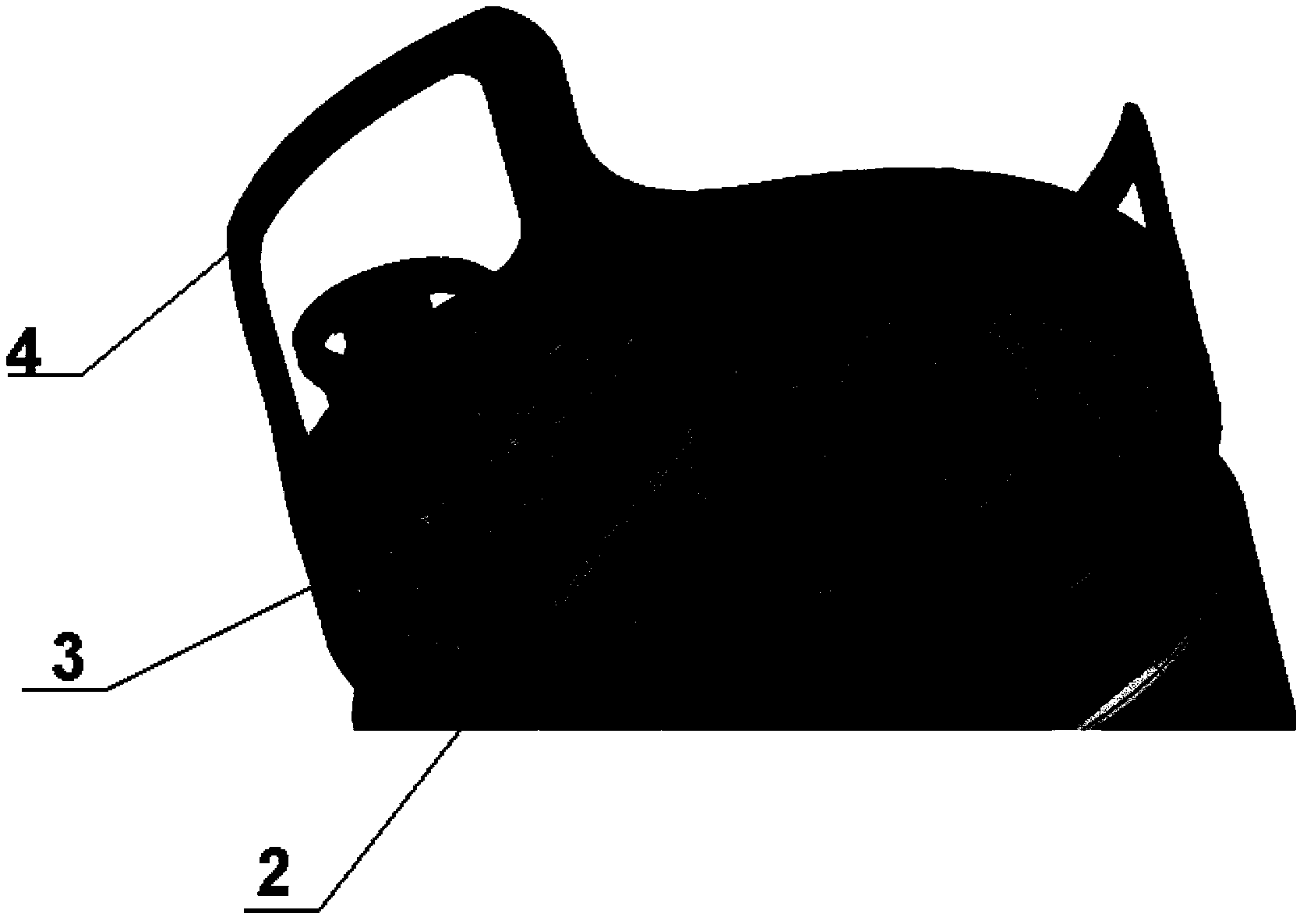

[0037] refer to Figure 1-5 , The present invention provides a foaming agent tank, comprising a tank body 1 and a foaming gun 2, wherein, the top of the tank body 1 is provided with a foaming gun interface, a feed port and an air inlet passage.

[0038] A cover 3 is provided on the feed inlet, and the cover 3 and the feed inlet are connected by threads, and the air inlet channel is arranged on the cover 3 .

[0039] The air intake passage is provided with a spring seat 31 positioned at the outlet end of the air intake passage. A spring 32 and a valve cover 33 are arranged between the spring seat 31 and the inlet of the air intake passage. The first end of the spring 32 is connected to the spring seat 31. Two ends link to each other with valve cover 33, and the upper surface area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com