Treatment method for heavy metal polluted sediment

A sediment and heavy metal technology, which is applied in the field of heavy metal polluted sediments, can solve the problems that large quantities of dredged sediments cannot be consumed in time, it is not suitable for simple application, and the soil differences are large, so as to reduce the cost of treatment and disposal, convenient operation and pertinence strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

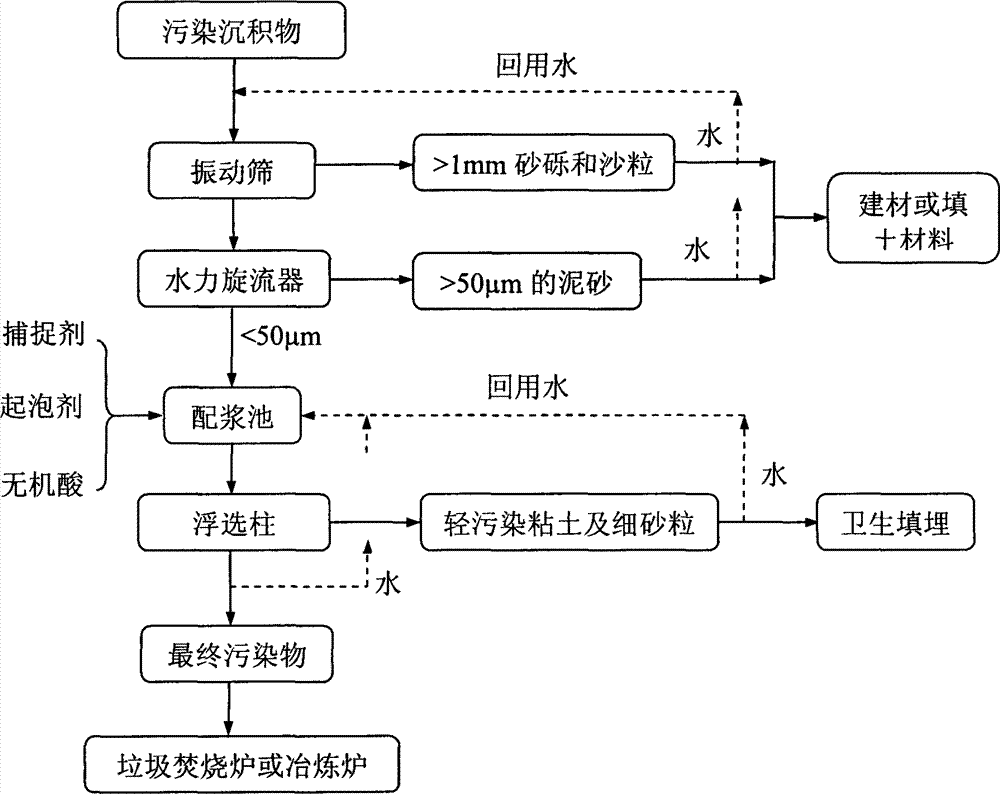

Method used

Image

Examples

Embodiment 1

[0017] Take 500kg of sediment from a heavy metal-polluted river course, and analyze the particles below 200 μm in the sediment. It can be seen from the table that most of the heavy metals are enriched in the fine particle sediments 1mm are separated and dehydrated, which can be directly used as building materials or soil filling materials, and the mud 50 μm can be directly used as building materials or earth filling materials after screening, and the remaining fine-grained sediments < 50 μm are only equivalent to about 1 / 9 of the original sediment mass.

[0018] Table 1 Distribution of heavy metal content in sediments with particle size

[0019] granularity mass distribution Cu Pb Zn Cd Cr 100~200μm 17.82% 68.88 58.13 325.90 1.29 120.14 50~100μm 9.31% 56.80 59.61 389.48 1.32 154.31 72.87% 695.4 494.57 3316.68 8.31 852.12 sediment 100% 524.31 376.30 2511.22 6.42 656.73

[0020] According to the solid waste ...

Embodiment 2

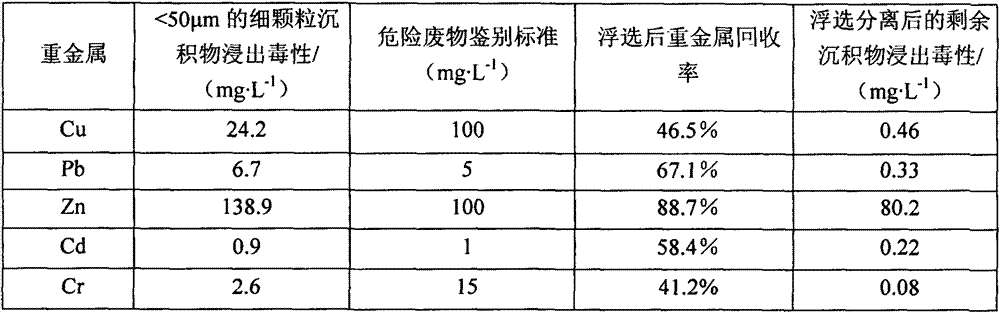

[0024] The sediment used was the same as in Example 1, and it was subjected to the same pre-screening. According to the solid waste toxic leaching method-sulfuric acid nitric acid method (HJ / T299-2007), the fine particle sediment <50μm was toxically leached, and the results are shown in Table 3. Weigh 100g of fine particle sediment <50μm and 500mL water into the slurry mixing tank, add 0.05 potassium ethylsulfonate and 0.05g methyl isobutyl carbinol into the slurry mixing tank, and add a small amount of hydrochloric acid to control the pH of the solution = 4. The prepared mud is sent to the flotation column for flotation. After separation, the floating foam enriched with heavy metals can be dehydrated and then sent to the waste incineration plant or smelter for treatment. The lightly polluted clay and fine sand that sank after flotation separation The heavy metals were analyzed and the recovery rate of heavy metals was calculated. The results are shown in Table 3. The lightly ...

Embodiment 4

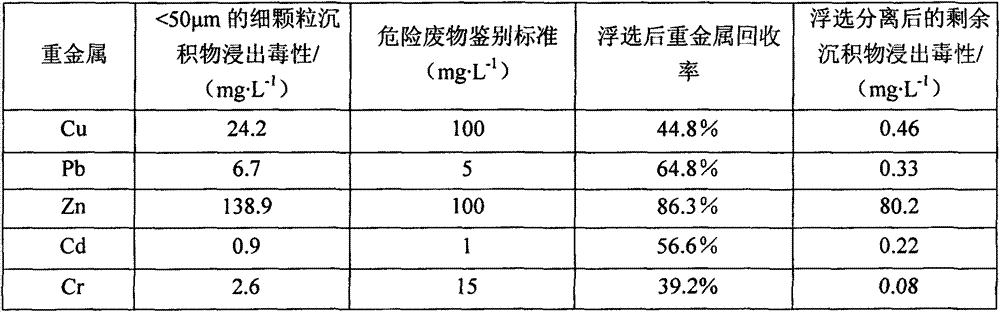

[0028] The sediment used was the same as in Example 1, and it was subjected to the same pre-screening. According to the solid waste toxic leaching method-sulfuric acid nitric acid method (HJ / T299-2007), the fine particle sediments <50 μm were toxically leached, and the results are shown in Table 2. Weigh 100g of <50μm fine particle sediment and 2L water into the slurry mixing tank, add a mixture of 0.4g kerosene and potassium ethylsulfonate (mass ratio 1:1), 0.4g pine oil in the slurry mixing tank, At the same time, a small amount of hydrochloric acid is added to control the pH of the solution to 6, and the prepared mud is sent to the flotation column for flotation. After separation, the floating foam enriched with heavy metals can be dehydrated and then sent to a waste incineration plant or smelter for treatment. The heavy metals in the lightly polluted clay and fine sand were analyzed, and the recovery rate of heavy metal was calculated. The results are shown in Table 4. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com