Low-voltage management system and method of distributed battery management system

A battery management system and a management system technology, applied in the field of battery management, can solve the problems of inability to realize low-voltage power management, difficulty in determining the current overload parameters of the main node, and current overload of the main node.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

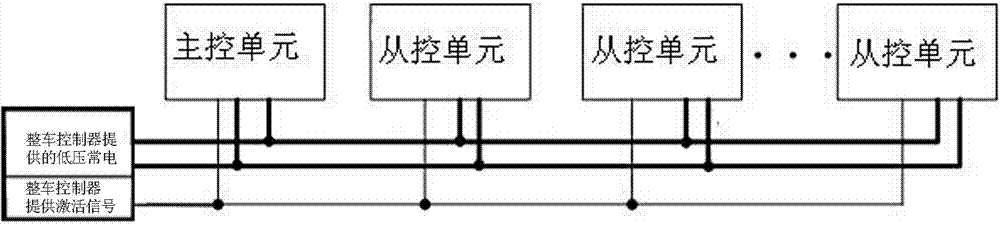

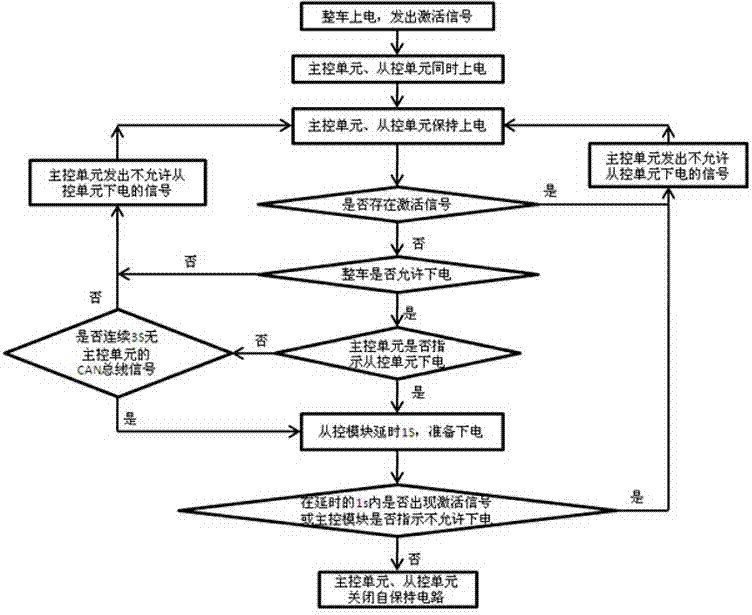

[0021] Such as figure 1 As shown, a low-voltage management system of a distributed battery management system includes a master control unit, multiple slave control units and a vehicle controller, and also includes a set of power lines, and the low-voltage constant power terminal of the vehicle controller Connected with the power line to provide low-voltage constant power for the master control unit and the slave control unit, the power line is provided with a master node and multiple sub-nodes, and the master node is connected to the master control unit to directly master The control unit provides power, and any one of the sub-nodes is individually connected to a slave control unit to directly provide power for the slave control unit at the same time. The main control unit is also connected to the vehicle controller through one channel of the CAN bus to receive information about whether the vehicle controller needs to be powered off at low voltage, and at the same time connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com