Plug body for beverage containers

A beverage and container technology, which is applied in the field of plugs for beverage containers, can solve problems such as inability to operate automatically and poor operability, and achieve the effects of preventing misoperation and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

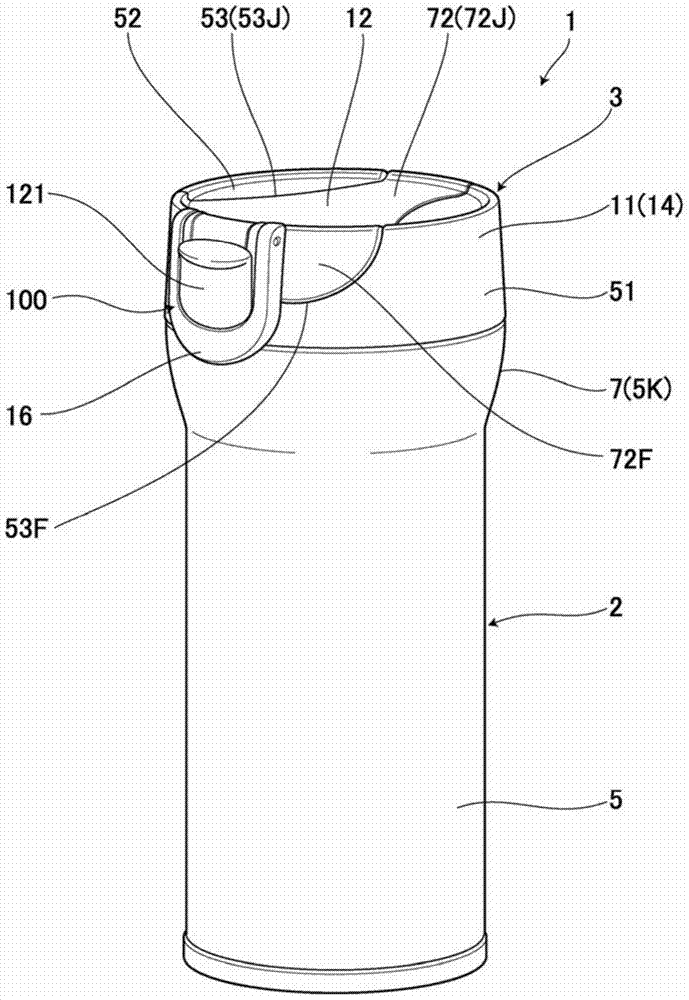

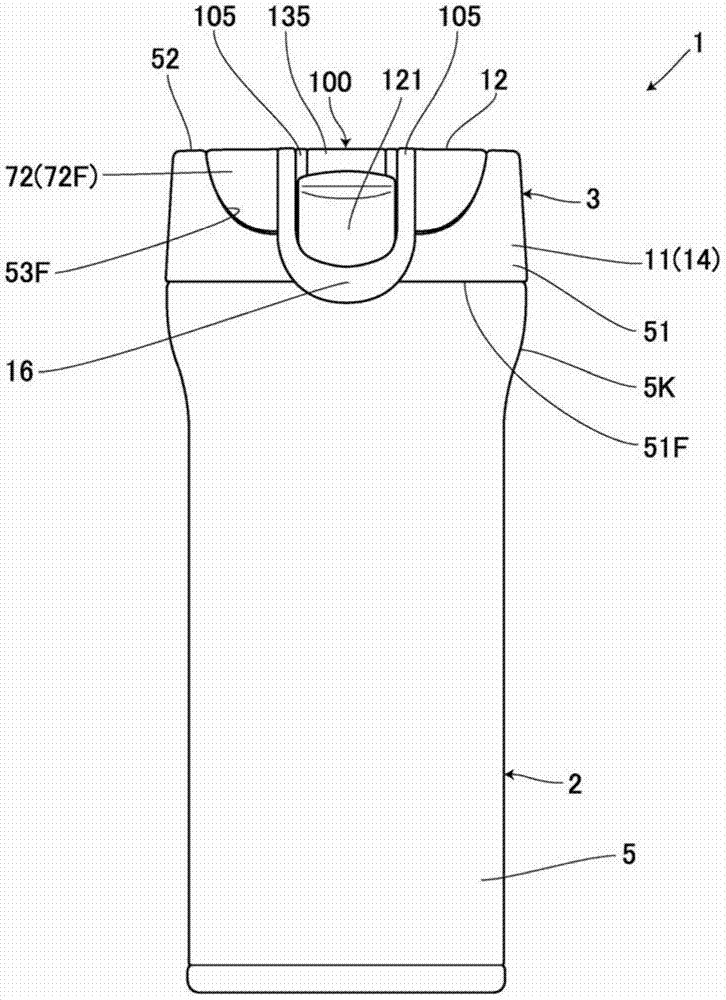

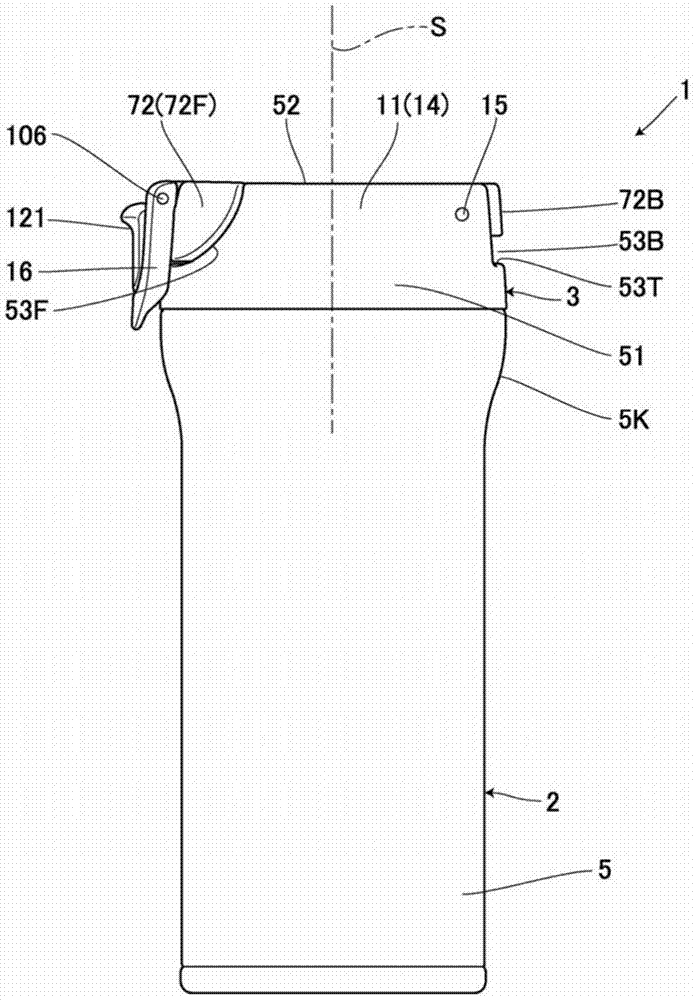

[0065] Below, use Figure 1 to Figure 27 The plug body of the first embodiment of the present invention will be described.

[0066] The plug body of this embodiment is used, for example, in Figure 1 ~ Figure 3 Shown is a container 1 for beverages. The beverage container 1 is composed of a metal container body 2 and a synthetic resin plug 3 .

[0067] The above-mentioned container body 2 has an inner cylinder 4 and an outer cylinder 5 integrally joined at the edge of an opening end 2A as an upper opening, and a heat insulating layer 6 that forms a space between the inner cylinder 4 and the outer cylinder 5 into a vacuum. Double layer insulation construction.

[0068] For example Figure 7 As shown, a head 7 is provided on the opening end 2A side of the container main body 2 . In the head portion 7, both the inner cylinder 4 and the outer cylinder 5 are formed to have larger diameters than the lower portion. In particular, an enlarged portion 5K that expands conically tow...

no. 2 approach

[0232] Figure 28 It is a schematic diagram showing the plug body of the second embodiment of the present invention. The same reference numerals are assigned to the same parts as those in Embodiment 1 described above, and detailed description thereof will be omitted.

[0233] In the present embodiment, a storage portion 85 is provided in the plug body hinge portion 82 , and a slide member 86 having a jig protrusion 90 is provided in the storage portion 85 .

[0234] In this embodiment, the same operations and effects as those of the above-mentioned first embodiment are exerted.

no. 3 approach

[0236] Figure 29 It is a schematic diagram showing the plug body of the third embodiment of the present invention. The same reference numerals are assigned to the same parts as those in the above-mentioned respective embodiments, and detailed description thereof will be omitted.

[0237] In this embodiment, a recess 91 serving as a clip receiving portion is provided on the outer end surface of the slide member 86 , and a clip protrusion 90 is provided on the inner surface of the inner wall portion 57 of the above-mentioned plug body hinge portion 82 corresponding to the recess 91 .

[0238] In this embodiment, the same operations and effects as those of the above-mentioned first embodiment are exerted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com