Combustion-restricted layer material applied to NEPE (Nitrate Ester Plasticized Polyether) propellant and preparation method of combustion-restricted layer material

A layer material, propellant technology, applied in the direction of adhesive, adhesive type, adhesive additive, etc., to achieve the effect of strong environmental adaptability, stable performance and good producibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

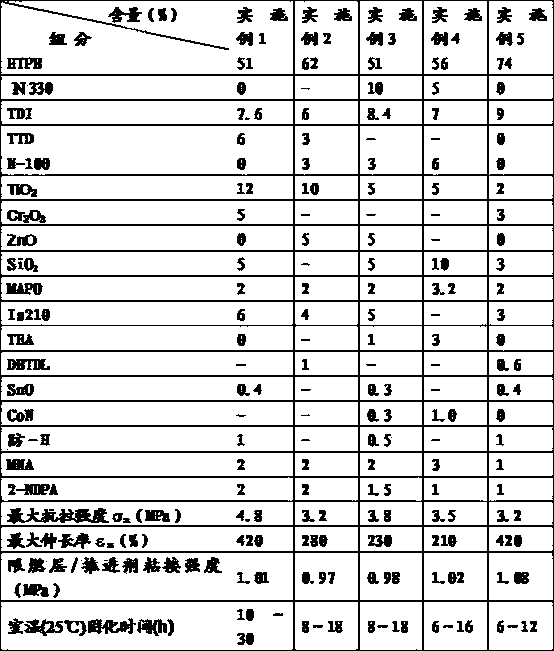

Embodiment 1

[0030] Embodiment 1 preparation process is as follows:

[0031] Add 6 grams of Is210 and 2 grams of MAPO to 51 grams of HTPB, add 12 grams of TiO after mixing for 5 minutes 2 , 5 grams of Cr 2 o 3 , 5 grams of SiO 2 , 1 gram of Fang-H, 2 grams of MNA, and 2 grams of 2-NDPA, mixed for 5 minutes, then added 7.6 grams of TDI and 6 grams of TTD, mixed for 10 minutes, then added 0.4 grams of SnO, mixed for 5 minutes, and discharged for use.

Embodiment 2

[0032] Embodiment 2 preparation process is as follows:

[0033] Add 4 grams of Is210 and 2 grams of MAPO to 62 grams of HTPB, add 10 grams of TiO after mixing for 5 minutes 2 , 5 grams of ZnO, 2 grams of MNA, and 2 grams of 2-NDPA, mixed for 5 minutes, then added 6 grams of TDI, 3 grams of N-100 and 3 grams of TTD, mixed for 10 minutes, then added 1 gram of DBTDL, mixed for 5 minutes, and the Materials are ready for use.

Embodiment 3

[0034] Embodiment 3 preparation process is as follows:

[0035] Add 10 grams of N330 to 51 grams of HTPB, add 5 grams of Is210, 1 gram of TEA and 2 grams of MAPO after mixing for 3 minutes, add 5 grams of TiO after mixing for 5 minutes 2 , 5 grams of ZnO, 5 grams of SiO 2 , 0.5 grams of anti-H, 2 grams of MNA, and 1.5 grams of 2-NDPA, mixed for 5 minutes, then added 8.4 grams of TDI, 3 grams of N-100, mixed for 10 minutes, then added 0.3 grams of SnO and 0.3 grams of CoN, mixed 5min, discharge and set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com