Embedded iron member and anchor bar connecting structure

A technology of pre-embedded iron parts and anchor bars, which is applied in basic structural engineering, construction, sheet pile walls, etc. Avoid overall welding deformation, facilitate construction, and avoid the effect of local welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

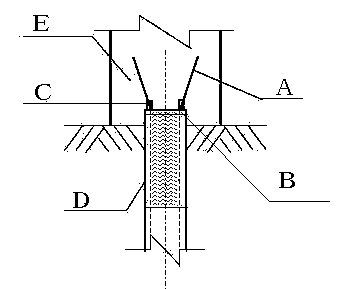

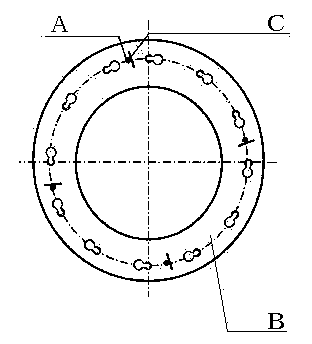

[0026] Embodiment 1: Connection structure and technology of pile end plate and anchor bar

[0027] Such as Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, this embodiment includes: anchor bars 1, pile rods 2, and anchor bolts 3. The ends of the pile rods 2 are provided with pile end plates 21, and the pile end plates 21 are provided with 12 tension nuts 211.

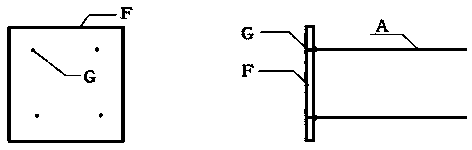

[0028] The anchor bolts 3 are divided into two groups, the first group: suitable for anchor bars with a diameter less than or equal to 18mm, such as Figure 5 As shown, the base material of the anchor bolt 3 is a HRB400 steel bar with a diameter of φ23mm to φ33mm, and the length of the steel bar is 25mm to 35mm. Position, inwardly process the internal thread matching the size of the anchor bar 1, the depth is 20mm to 30mm, and the anchor bolt 3 is completed; the second group: suitable for anchor bars with a diameter greater than 18mm, such as Figure 6 As shown, the base material of the anchor bolt 3 is a HR...

Embodiment 2

[0036] Embodiment 2: Connection structure and technology of embedded steel plate and anchor bar

[0037] Such as Figure 5 , Figure 6 , Figure 7 , Figure 9 As shown, this embodiment includes: anchor bars 1 and embedded steel plates 4 . On the pre-embedded steel plate 4, four holes 41 are drilled, the size of the holes 41 cooperates with the anchor bar 1, an internal thread is set in the hole 41, the hole 41 is a nut, and an external thread 11 is processed at one end of the anchor bar 1, and The external thread 11 cooperates with the internal thread of the hole 41, the anchor bar 1 is a bolt, and the anchor bar 1 is threadedly connected with the embedded steel plate 4 through the external thread 11.

[0038] see Figure 5 , Figure 6 , Figure 7 , Figure 9 , the concrete technological process of embodiment two is as follows:

[0039] ① Cut the pre-embedded steel plate 4 into the size required by the design, select the size of the drilled hole 41 at the required posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com