Polycrystalline diamond composite tooth, preparation method and down-hole drill bit

A technology of polycrystalline diamond and composite teeth, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of poor bonding force, poor impact toughness of polycrystalline diamond composite teeth, etc., and achieve the reduction of tensile stress concentration and high body bonding force, improve the effect of impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The polycrystalline diamond composite tooth of the present embodiment comprises a cemented carbide substrate and a polycrystalline diamond layer, and an impact-resistant layer is arranged between the cemented carbide substrate and the polycrystalline diamond layer, and the impact-resistant layer consists of the following mass percentage Component composition: Diamond 75%, WC15%, Co6%, Ni2%, TiC2%. The cemented carbide matrix is composed of the following components in mass percentage: 10% Co, 90% WC; wherein the grain size of WC is 2.5-5.0 μm. The mass ratio of the impact-resistant layer to the polycrystalline diamond layer is 1:2. The polycrystalline diamond layer is composed of the following components in mass percentage: 50% of diamond with a particle size of 50-60 μm, 30% of diamond with a particle size of 30-40 μm, 10% of diamond with a particle size of 10-20 μm, and 10% of Co.

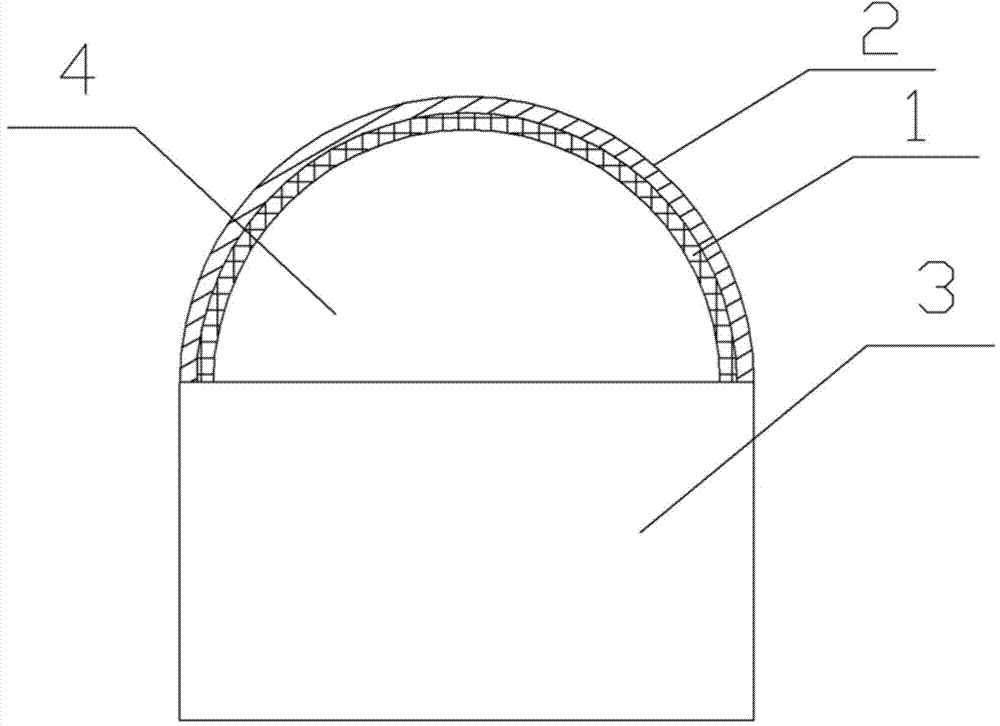

[0042] The structure of the polycrystalline diamond composite tooth of the present e...

Embodiment 2

[0052] The polycrystalline diamond composite tooth of this embodiment comprises a cemented carbide substrate and a polycrystalline diamond layer, and an impact-resistant layer is arranged between the cemented carbide substrate and the polycrystalline diamond layer, and the impact-resistant layer consists of the following mass percentage Composition: Diamond 80%, WC10%, Co3%, Ni4%, TiC3%. The cemented carbide matrix is composed of the following components in mass percentage: Co8%, WC92%, wherein the grain size of WC is 2.5-5.0 μm. The mass ratio of the impact-resistant layer to the polycrystalline diamond layer is 1:3. The polycrystalline diamond layer is composed of the following components in mass percentage: 40% diamond with a particle size of 50-60 μm, 40% diamond with a particle size of 30-40 μm, 16% diamond with a particle size of 10-20 μm, and 4% Co.

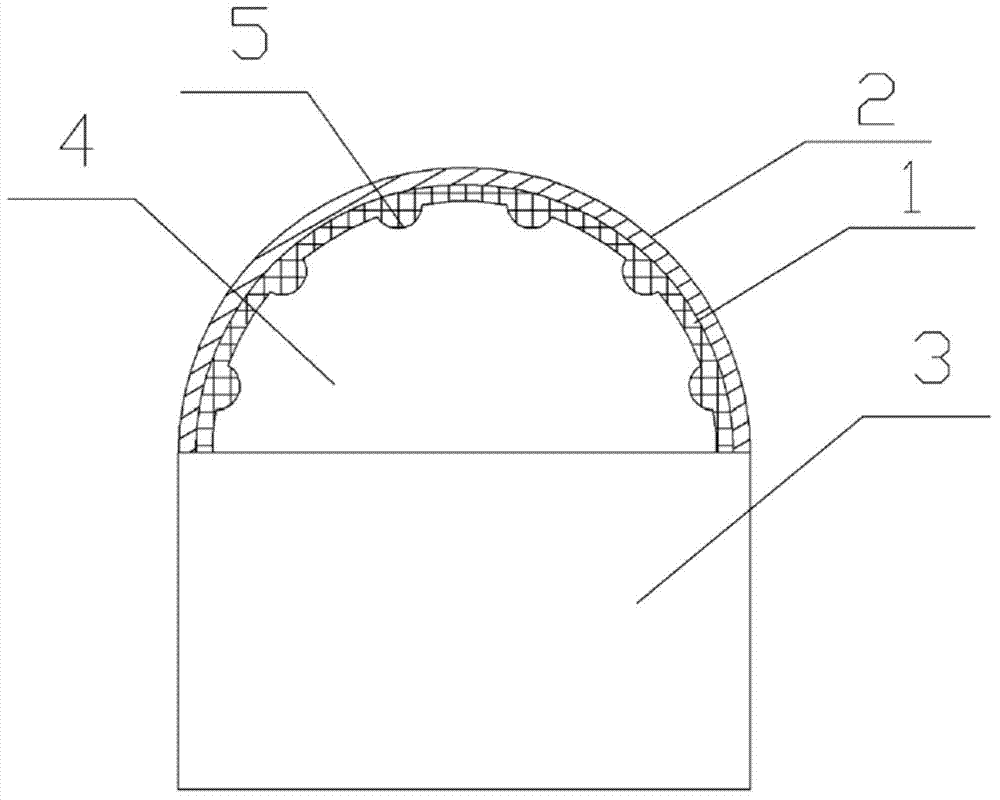

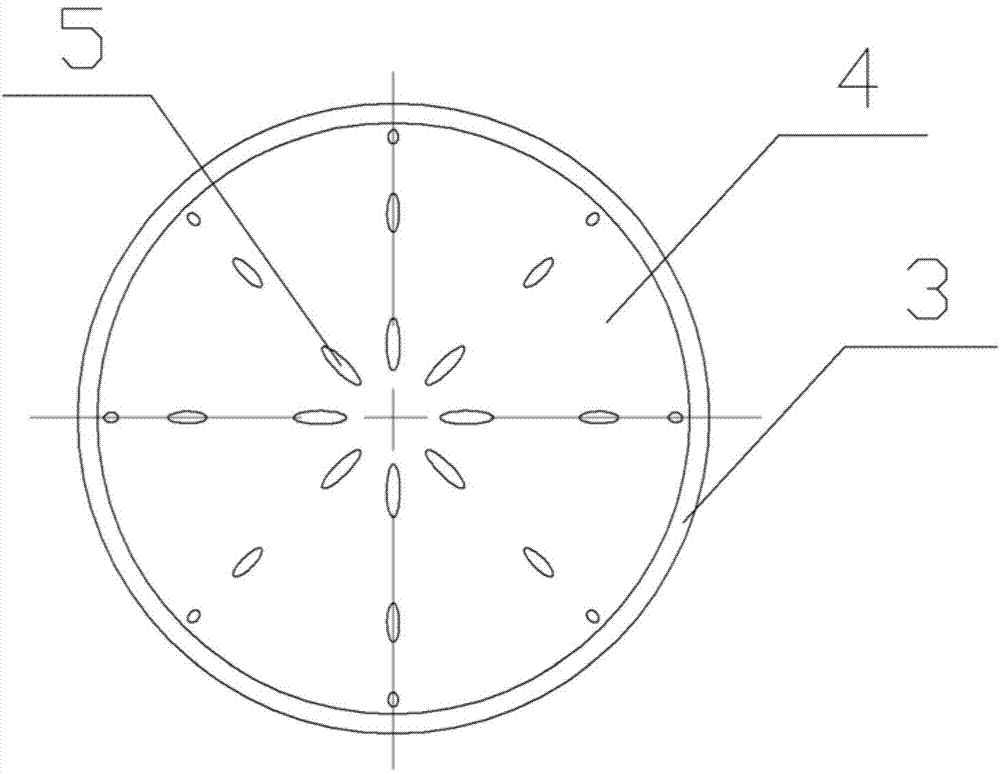

[0053] The structure of the polycrystalline diamond composite tooth of the present embodiment is as figure 2 As sho...

Embodiment 3

[0063] The polycrystalline diamond composite tooth of this embodiment comprises a cemented carbide substrate and a polycrystalline diamond layer, and an impact-resistant layer is arranged between the cemented carbide substrate and the polycrystalline diamond layer, and the impact-resistant layer consists of the following mass percentage Component composition: Diamond 78%, WC12%, Co7%, Ni2%, TiC1%. The cemented carbide matrix is composed of the following components in mass percentage: Co6%, WC94%, wherein the grain size of WC is 2.5-5.0 μm. The mass ratio of the impact-resistant layer to the polycrystalline diamond layer is 1:4. The polycrystalline diamond layer is composed of the following components in mass percentage: 40% diamond with a particle size of 50-60 μm, 33% diamond with a particle size of 30-40 μm, 20% diamond with a particle size of 10-20 μm, and 7% Co.

[0064] The preparation method of the polycrystalline diamond composite tooth of the present embodiment comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com