an impeller structure

A technology of impeller and impeller cover, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc. It can solve the problems of high energy consumption, low structural performance of impellers, and high cost of use. Achieve the effects of low energy consumption, compact structure and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

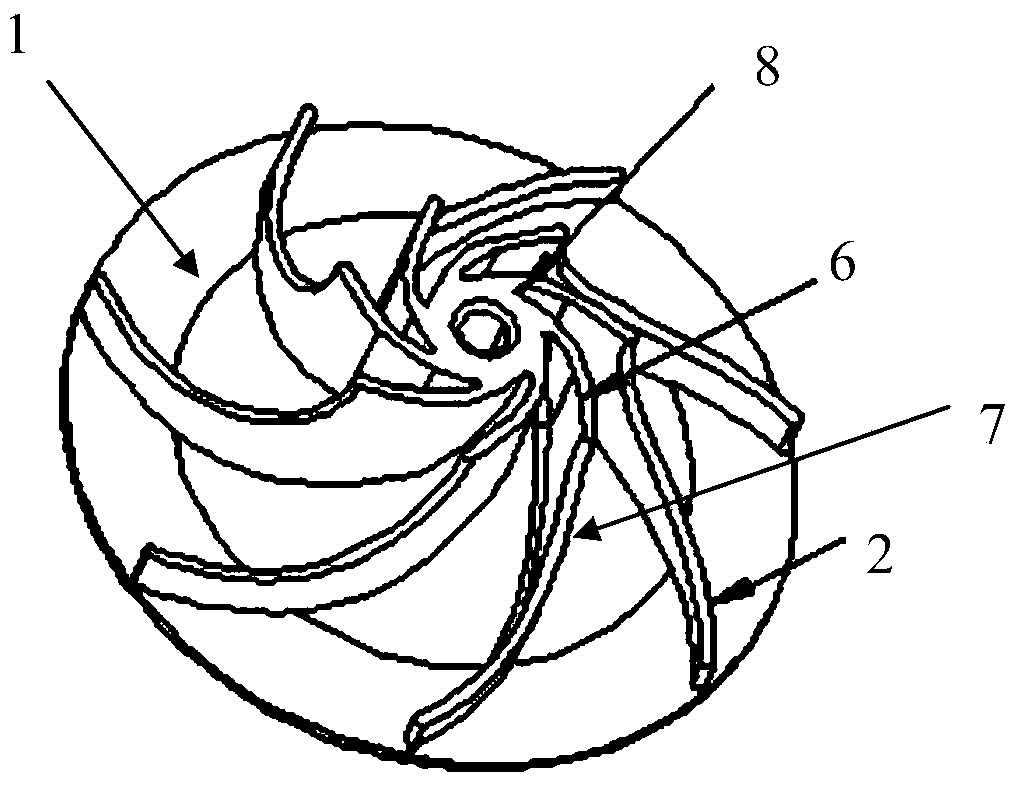

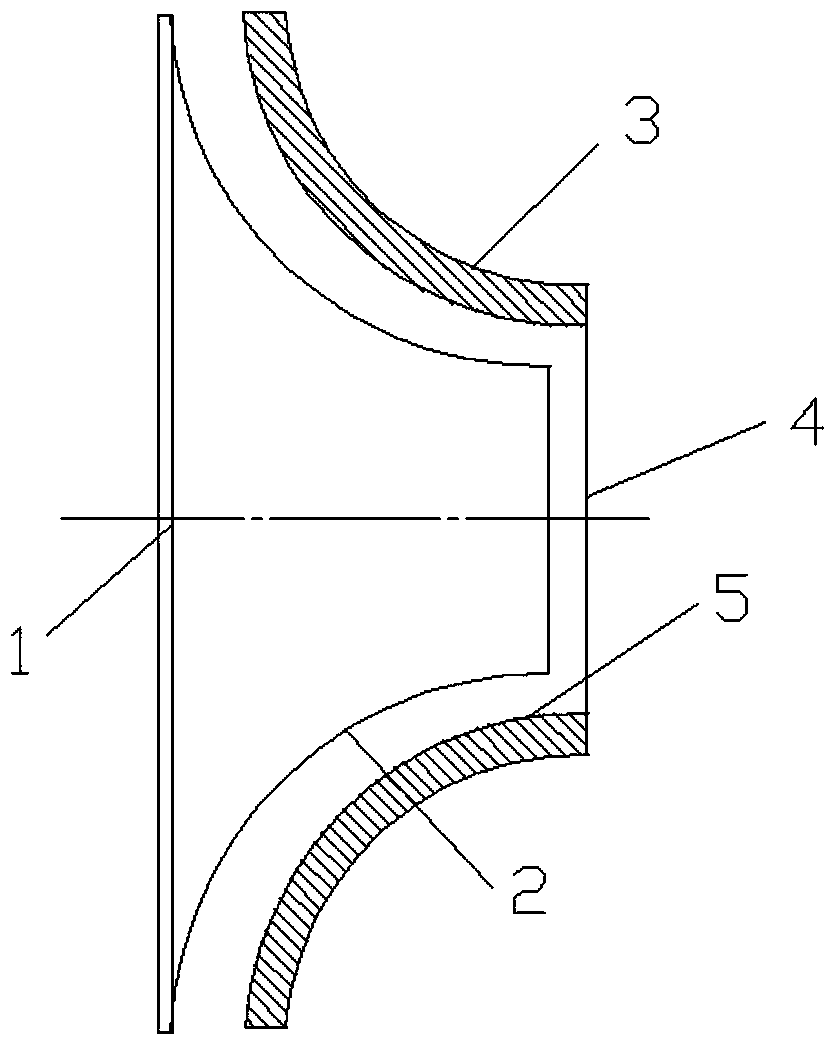

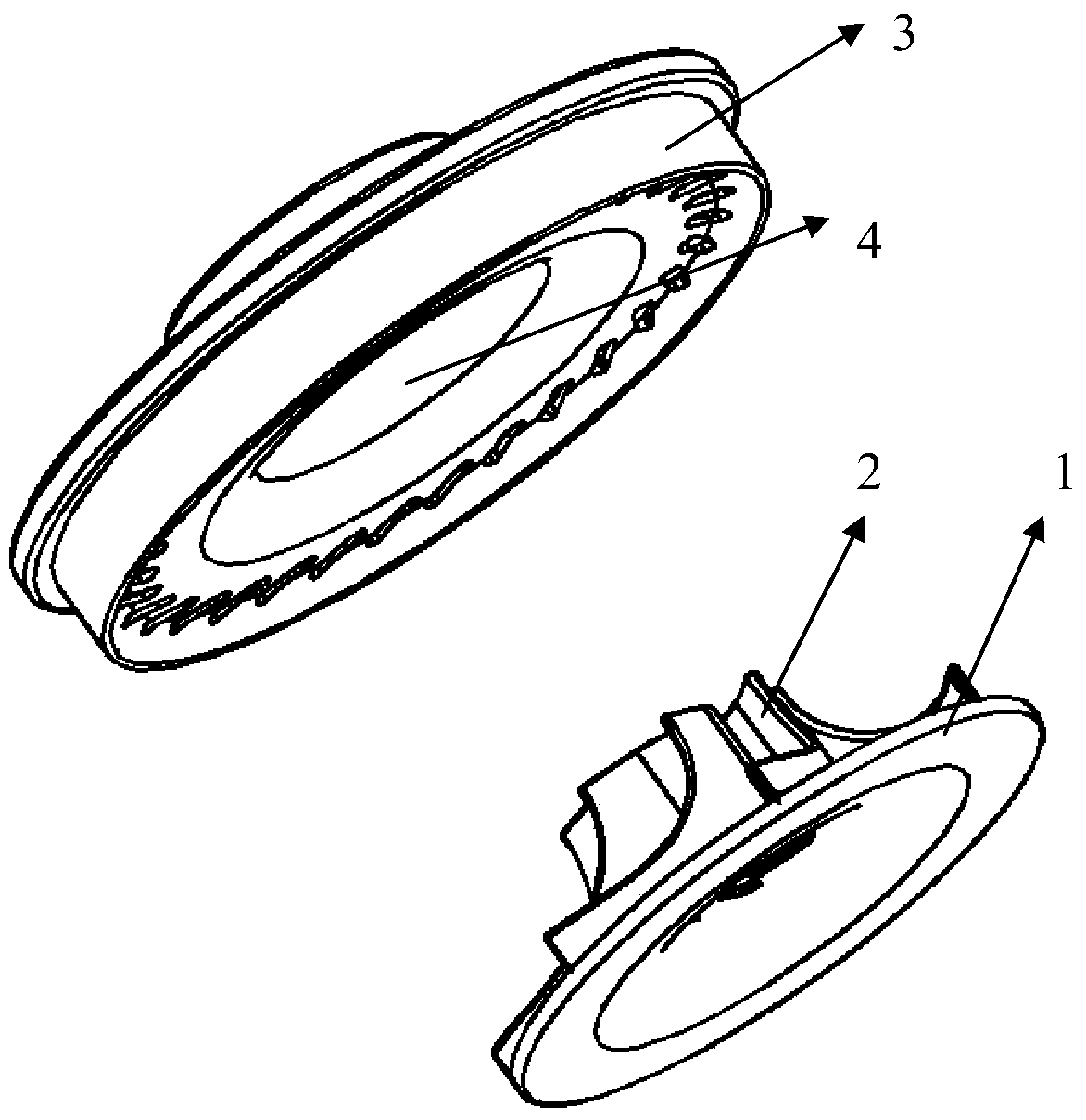

[0029] The impeller of the traditional vacuum cleaner motor is an aluminum impeller, which is a closed impeller structure, usually including an upper cover, a lower cover, and blades arranged between the upper and lower covers. The working efficiency of the closed impeller is relatively high. However, it is difficult to manufacture, and the upper and lower cover plates and blades of the aluminum impeller are assembled, the structure is complex, the volume is generally large, the quality is heavy, the production cost is high, and the noise is relatively large during operation. Compared with the closed impeller, the semi-open impeller and the open impeller are relatively smaller in volume, but their work efficiency is low, and they cannot meet the needs of high-speed use.

[0030] Aiming at the deficiencies in the prior art, the present invention provides an impeller structure. By adopting the impeller structure in which the lower cover plate and blades are integrally formed to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com