Laser switching-off system with high damage resistance

A laser, laser technology, applied in laser parts, laser cooling devices, optics, etc., can solve the problems of weakening the performance of the shutter, reducing the service life of the shutter, burning damage, etc., to eliminate instability and improve resistance. Damage ability, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

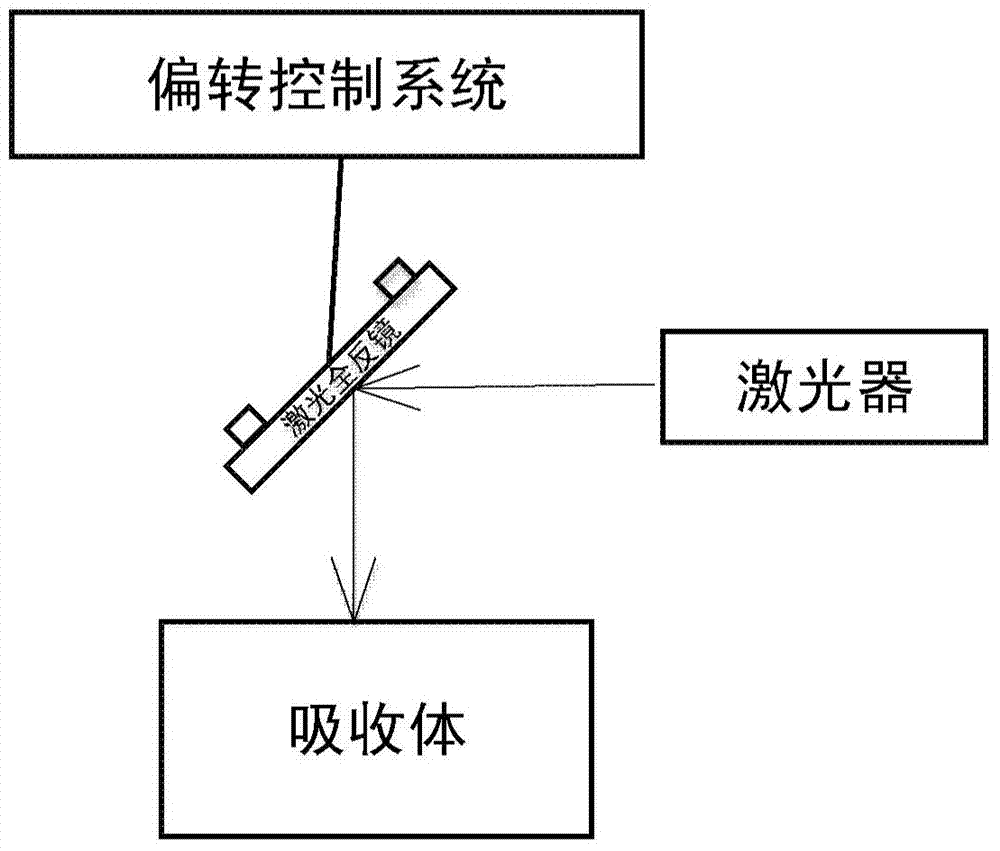

[0013] Attach here figure 2 An overall description of the system. Such as figure 2 As shown, the laser shutter system with high damage resistance and capable of withstanding high-power lasers of the present invention includes a deflection control system, a total mirror, and an absorber located on the optical path of the total mirror.

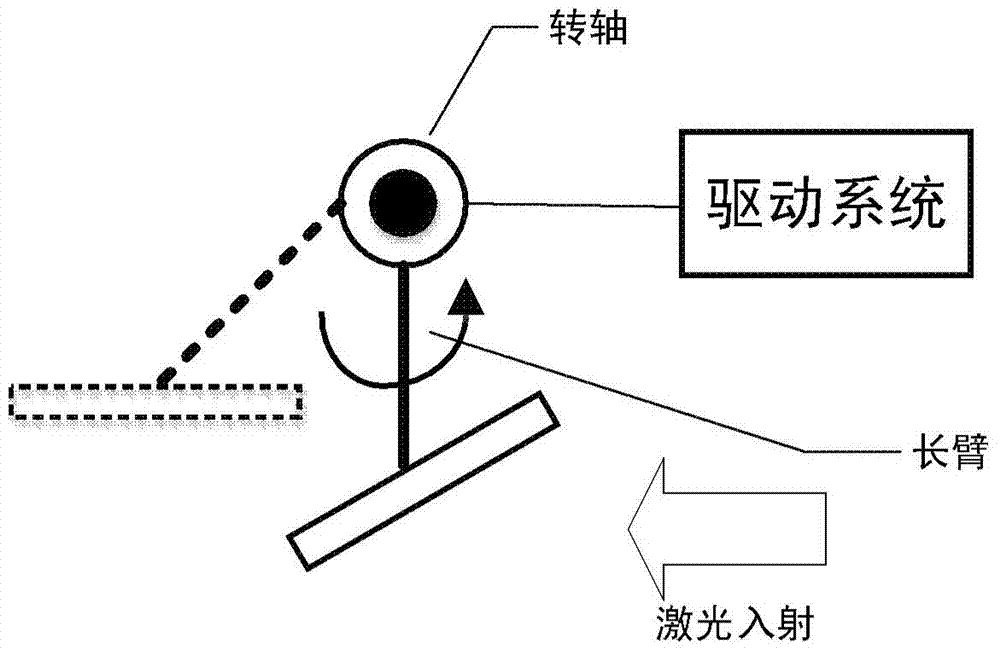

[0014] The deflection control system controls the movement of the total mirror in and out of the laser light path by means of rotation. When the processing process needs to be interrupted, the total mirror rotates and moves into the laser light path, and the total mirror changes the propagation direction of the laser to make it deflect, thereby cutting off the transmission of the laser. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com