Inclined scanning stitching method of write-through lithography system

A technology of oblique scanning and lithography system, which is applied in the field of oblique scanning and splicing of direct-writing lithography system, which can solve the problems of image quality degradation and strip splicing misalignment, etc., and achieve the effect of improving splicing, increasing utilization rate, and improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

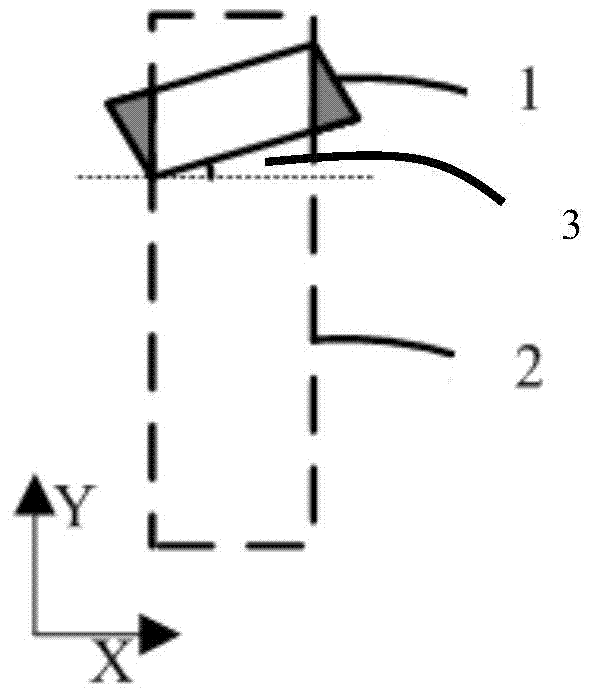

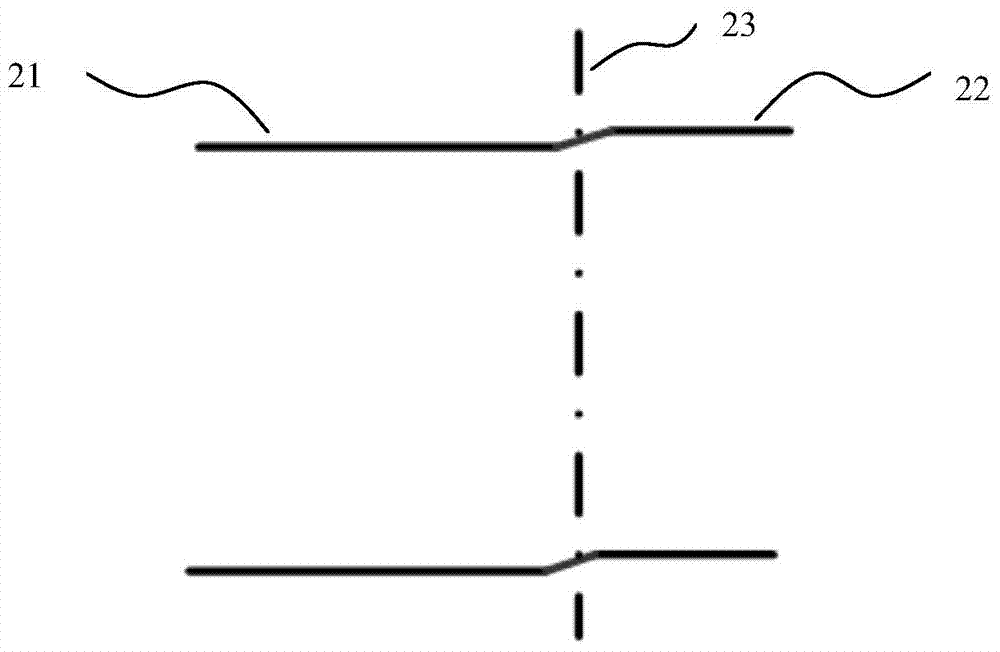

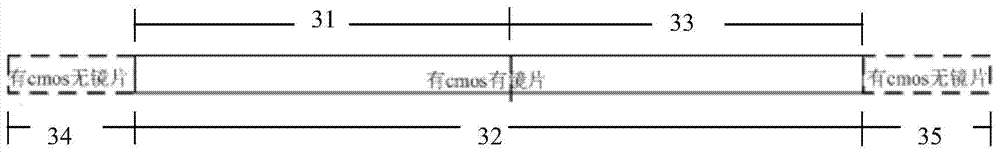

[0037] The present invention proposes a method for improving splicing effect under oblique scanning in a direct writing photolithography system. The number of DMD lines used in the present invention is M=512, and the oblique factor N=8. Since the width of a large picture is much larger than that of DMD, it is necessary to expose multiple strips and splicing the strips together to form a complete graphic, so that the graphic quality between the strips is particularly important. important.

[0038] In the tilt scan, the tilt factor is 8, so every 8 rows of lenses in the lower computer, the data is shifted one bit to the right, and the current bit is filled with 0, then 64 times of misplacement and zero filling are required to fill 512 rows of lenses. That is to say, 0 0s are added at the beginning of the first 8 lines, 1 0 is added to the second 8 lines, 2 0s are added to the third 8 lines, and so on, 63 zeros are added to the 64th 8 lines, Such as Figure 5 As shown, (the dot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com