Method and system for having intelligent control over granary ventilation system

A ventilation system and intelligent control technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of long time consumption, moldy grain, high labor intensity, etc., and achieve the effect of optimizing the grain storage environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

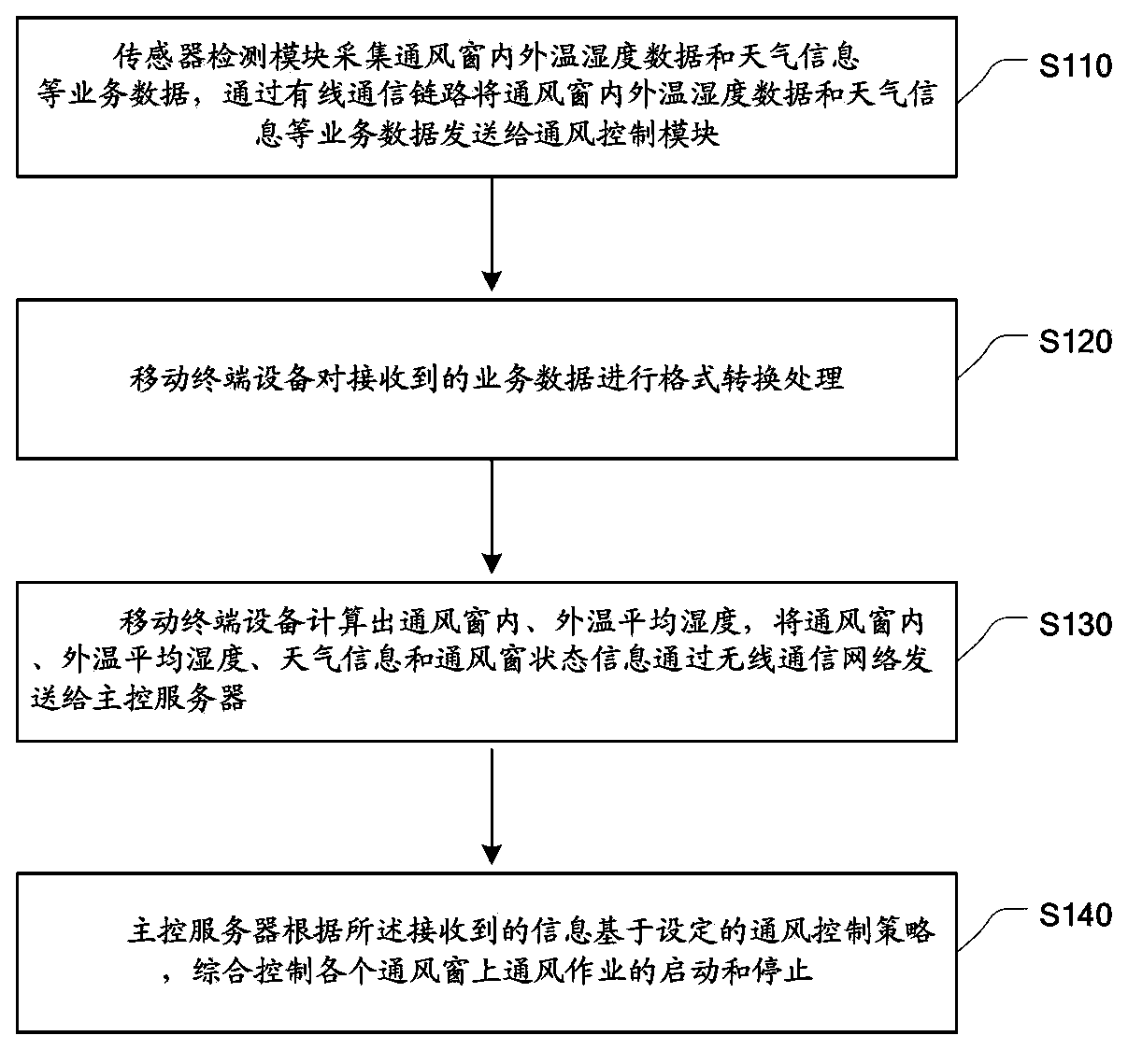

Method used

Image

Examples

Embodiment 2

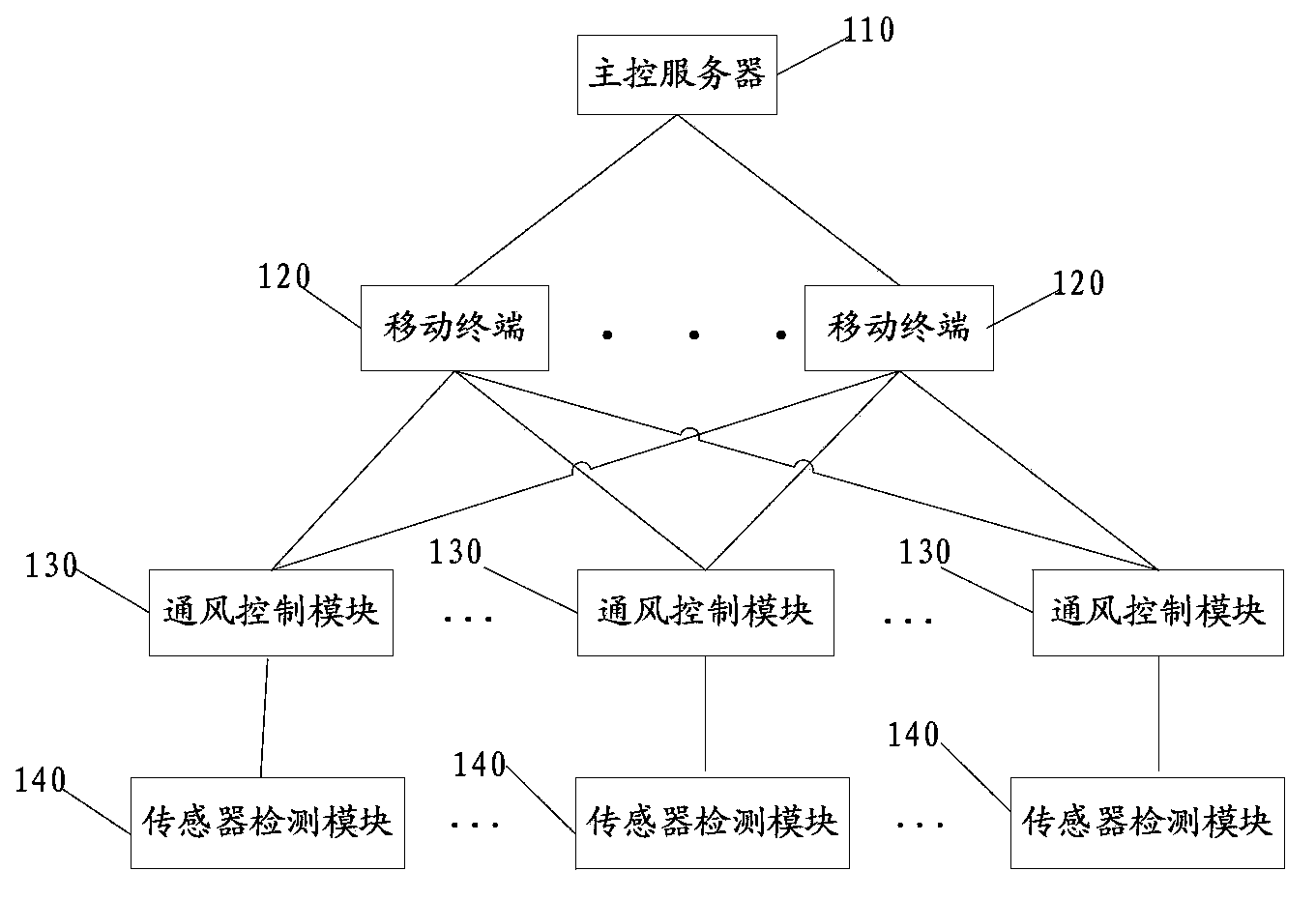

[0058] This embodiment provides a specific structural diagram of a system for intelligently controlling the ventilation system of the grain depot as shown in image 3 As shown, it includes: a ventilation control module, a mobile terminal, a main control server and a sensor detection module.

[0059] The ventilation control module, the mobile terminal and the main control server all include a wireless communication module, and they are connected and communicated through a wireless communication network.

[0060] The main control server monitors the entire grain depot system, can add or reduce the number of mobile terminals used to remotely control the ventilation control modules, and can specify the number of mobile terminals to control the corresponding ventilation control modules. The mobile terminal may be a portable mobile terminal such as a smart watch, a mobile phone, or a tablet computer.

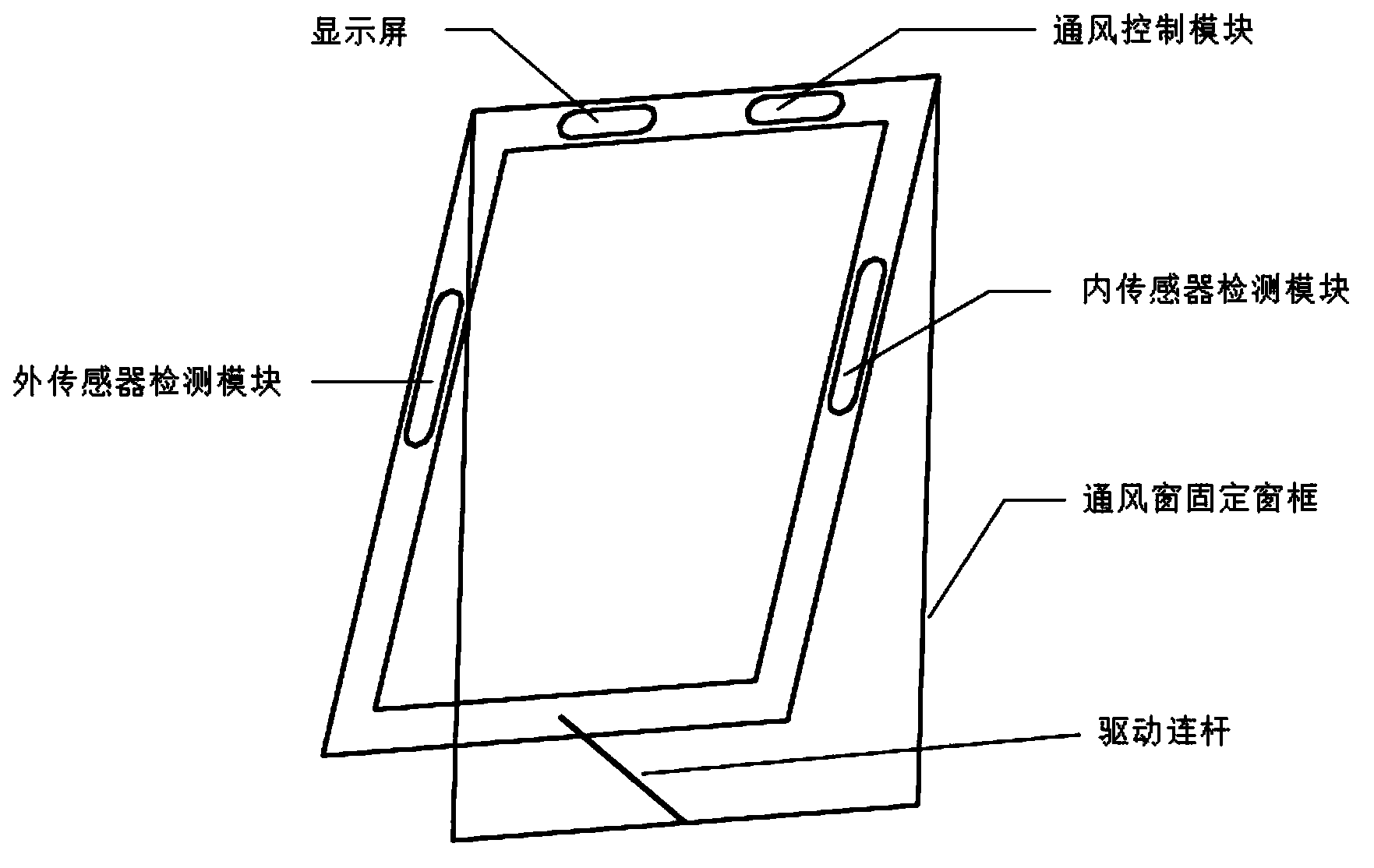

[0061] Specifically, the sensor detection module is configured to be installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com