Lug piece breakage detection method for high-speed rail overhead line system supporting device based on HOG features and two-dimensional Gabor wavelet transformation

A wavelet transform and ear piece fracture technology, which is applied in instruments, calculations, character and pattern recognition, etc., can solve problems such as low degree of automation and inability to detect component faults, and achieves reduced workload, objective and high detection results. Smart level effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

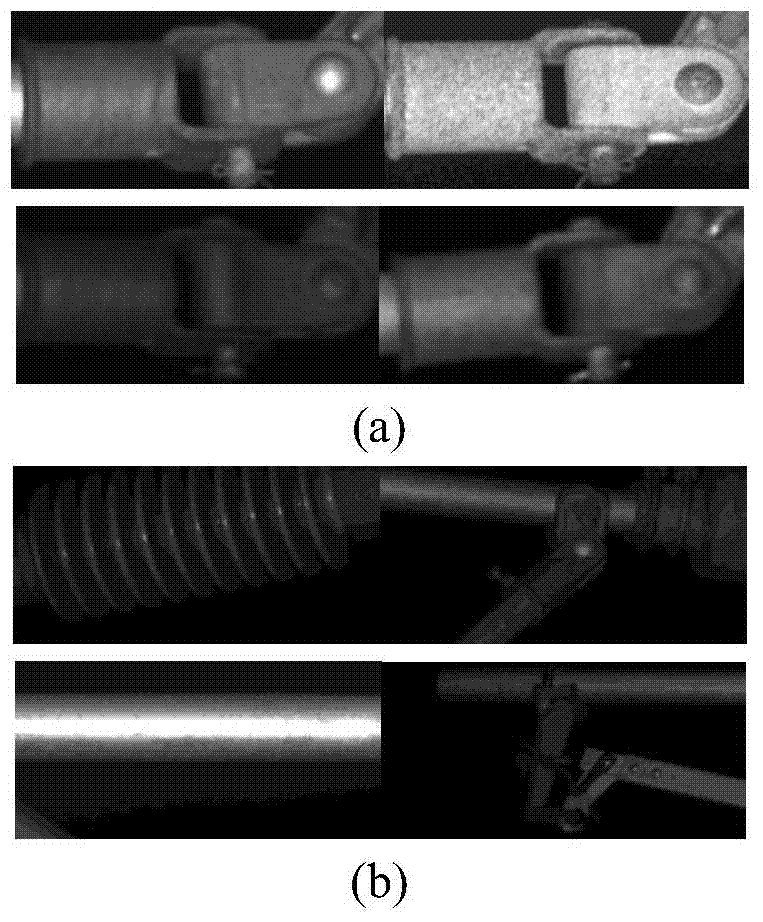

[0051] Training samples are manually intercepted from the catenary support and suspension device images collected earlier. Among them, the positive sample contains the rotated ears, and the rotated ears occupy the main body position in the middle of the image, figure 1 (a) shown. Negative samples randomly contain other catenary components unrelated to the rotating binaural, figure 1 (b) shown. In order to reduce the difference in HOG features caused by "alignment problems", the aspect ratio of positive and negative samples is fixed at 2:1 when intercepting, and the size is normalized to 128×64 pixels (the size of the detection window).

[0052] Extract HOG features for positive and negative samples: first divide the image into several square cells of the same size. Then merge every four adjacent cells into a square block, and the blocks can overlap each other. Use (1)-(4) to calculate the gradient magnitude (m(x,y)) and direction (θ(x,y)) of each pixel, and calculate the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com