High-voltage static protection structure

A technology for protecting structures and high-voltage static electricity, which is applied to circuits, electrical components, and electric solid devices. The effect of capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

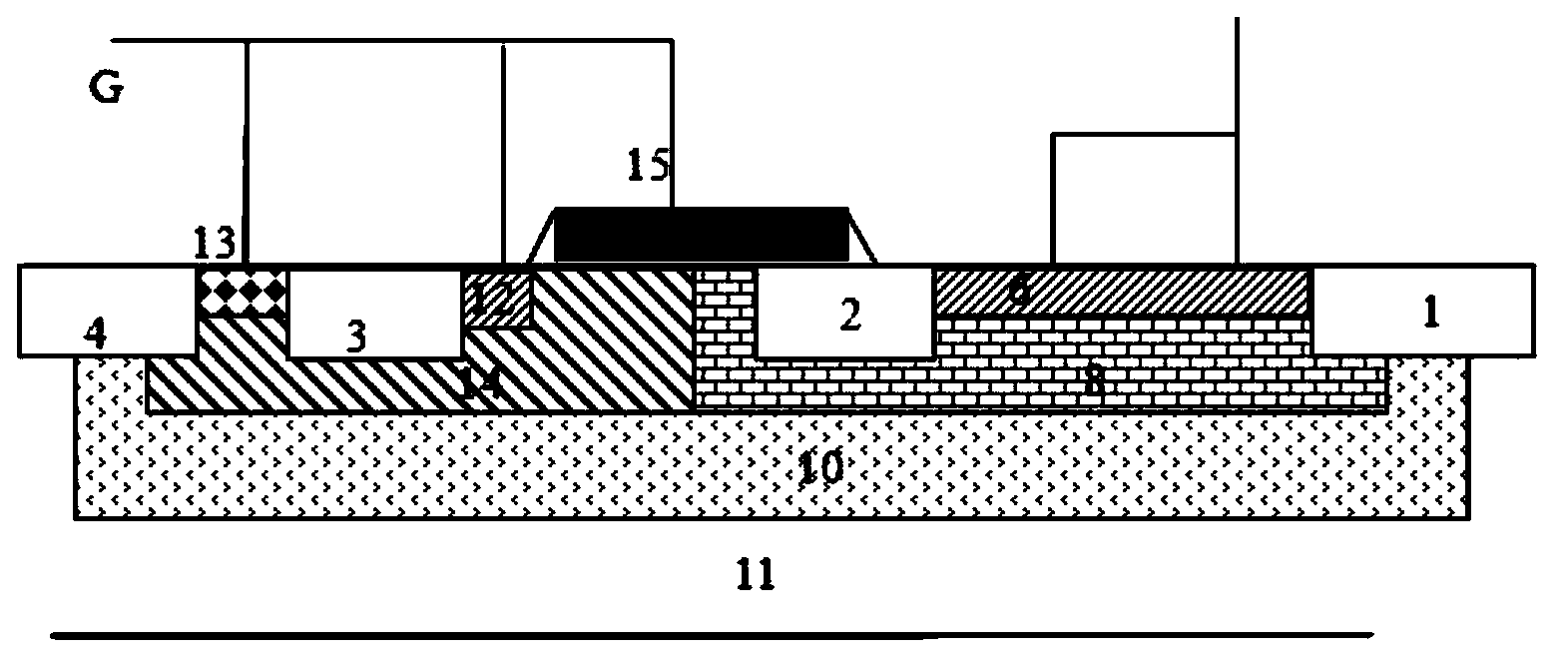

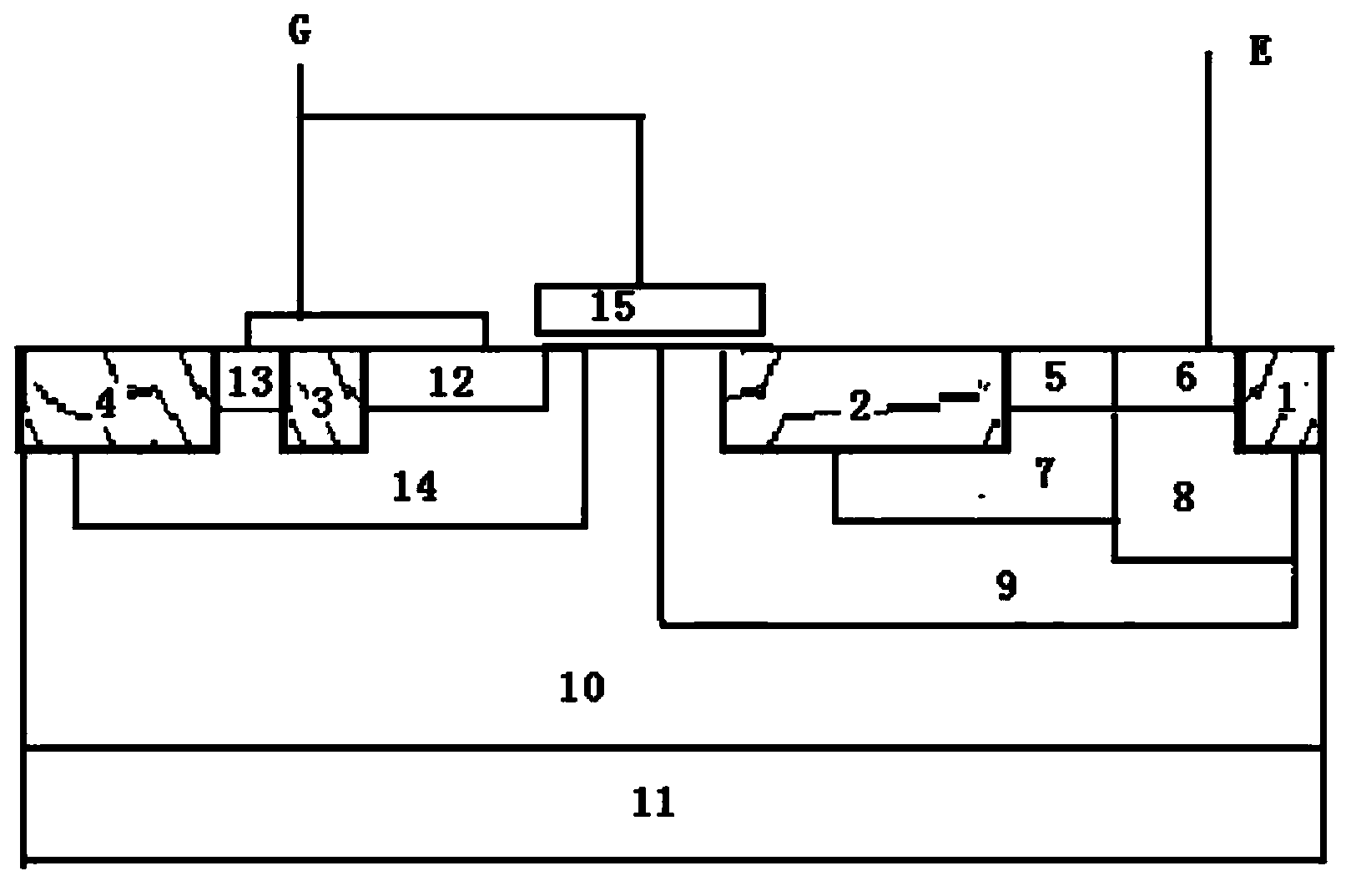

[0031] An embodiment of the present invention includes: an N-type LDMOS is placed entirely in the N-type buried layer 10 above a silicon substrate 11; the active region on the right side of the polysilicon gate 15 is the drain region of the LDMOS, and the drain region Including the first P+ diffusion region 5 and the P- implantation region 7 below it, the first N+ diffusion region 6 and the N- implantation region 8 below it, the first P+ diffusion region 5 and the first N+ diffusion region 6 are adjacent , the P-implantation region 7 is adjacent to the N-implantation region 8; the first N+ diffusion region 6 has a first field oxygen region 1 on the side away from the polysilicon gate 15, and the first P+ diffusion region 5 is close to a side of the polysilicon gate 15 The side has a second field oxygen region 2;

[0032] The active region on the left side of the polysilicon gate 15 is the source region of the N-type LDMOS, and the source region includes the second N+ diffusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com