Electricity generation energy dissipation braking type automobile retarder

A technology of power generation energy consumption and retarder, which is applied in the field of retarder and automobile auxiliary brake, which can solve the problems of rotor thermal deformation and performance degradation, and achieve the effect of prolonging service life, improving service conditions and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

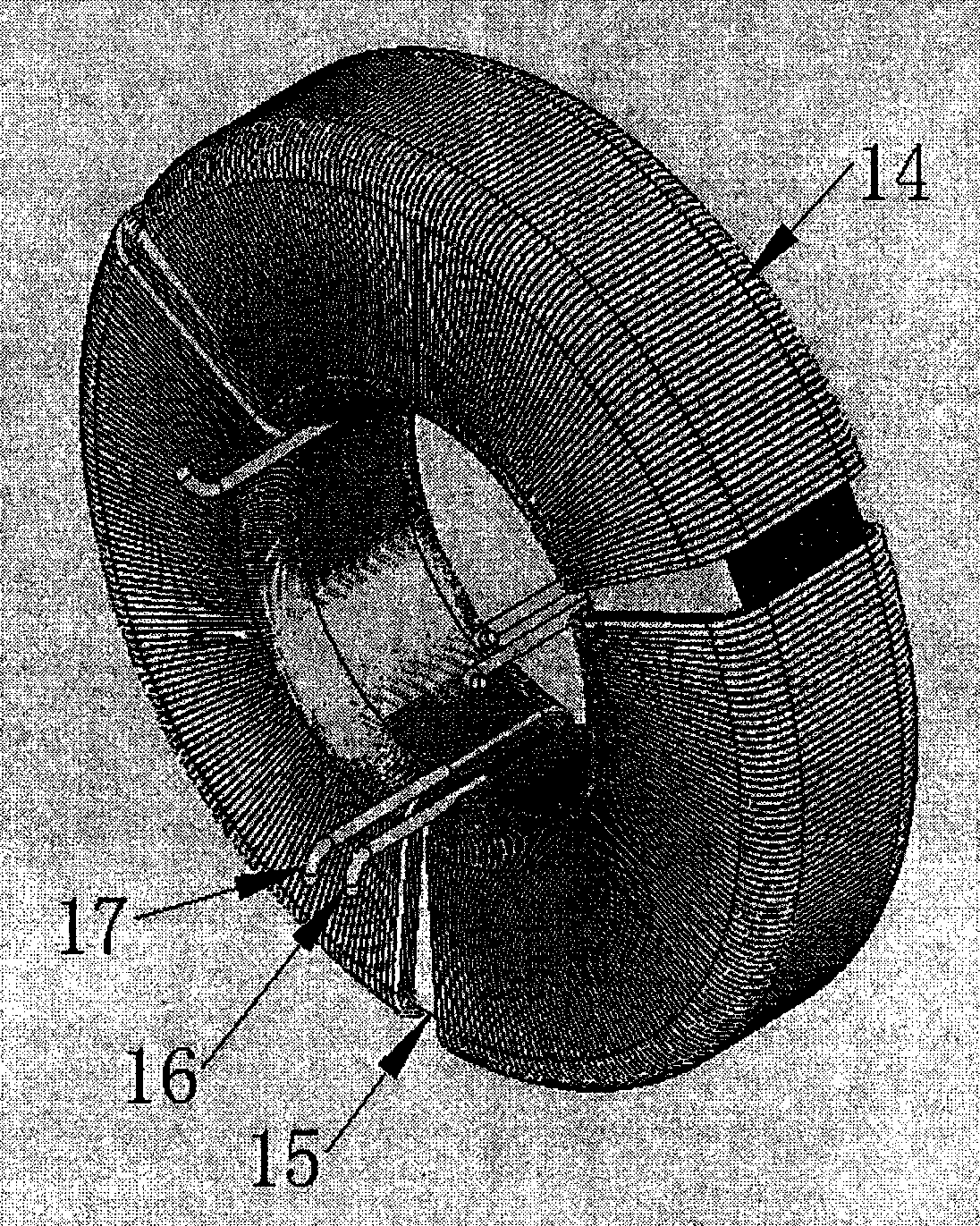

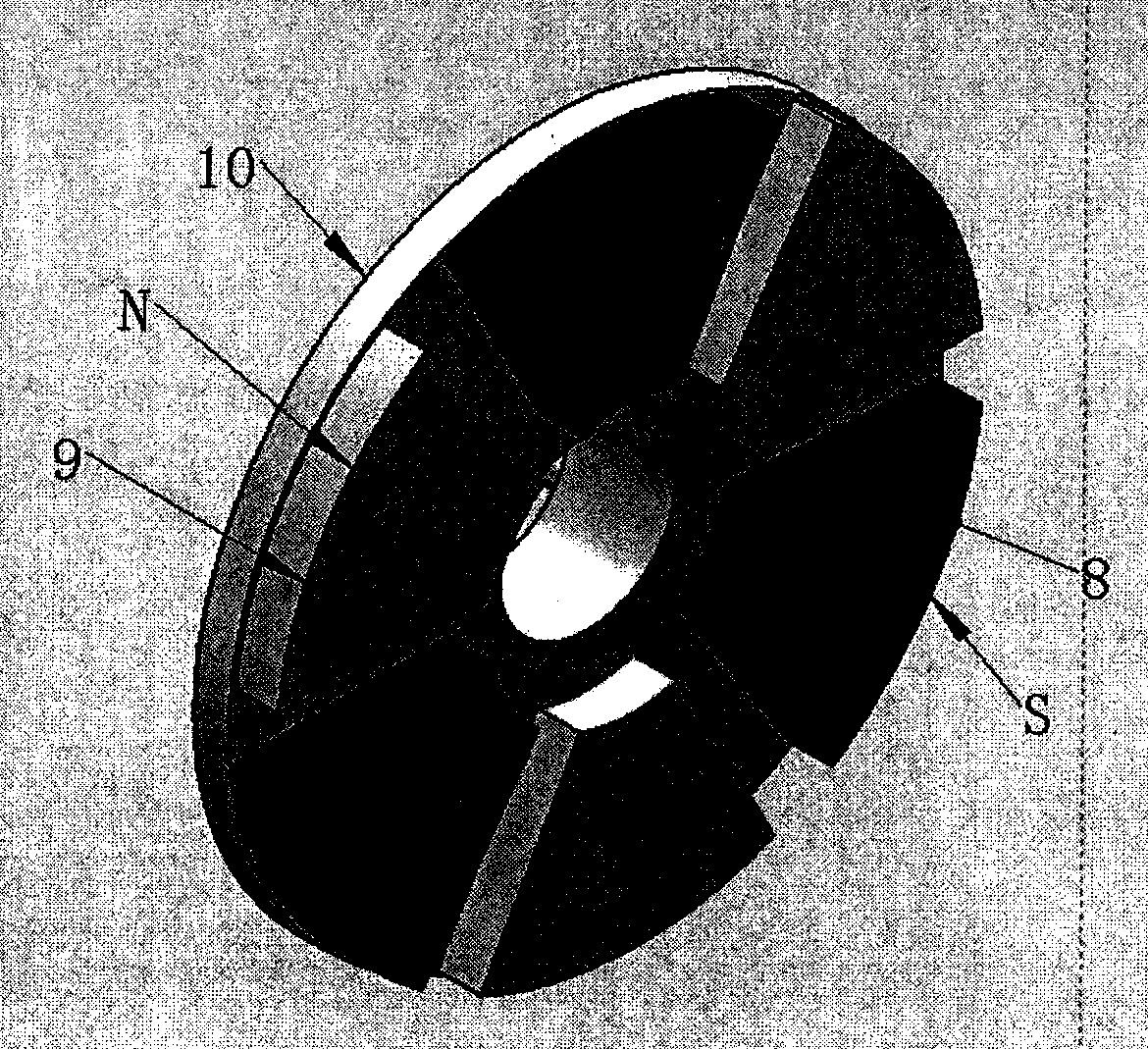

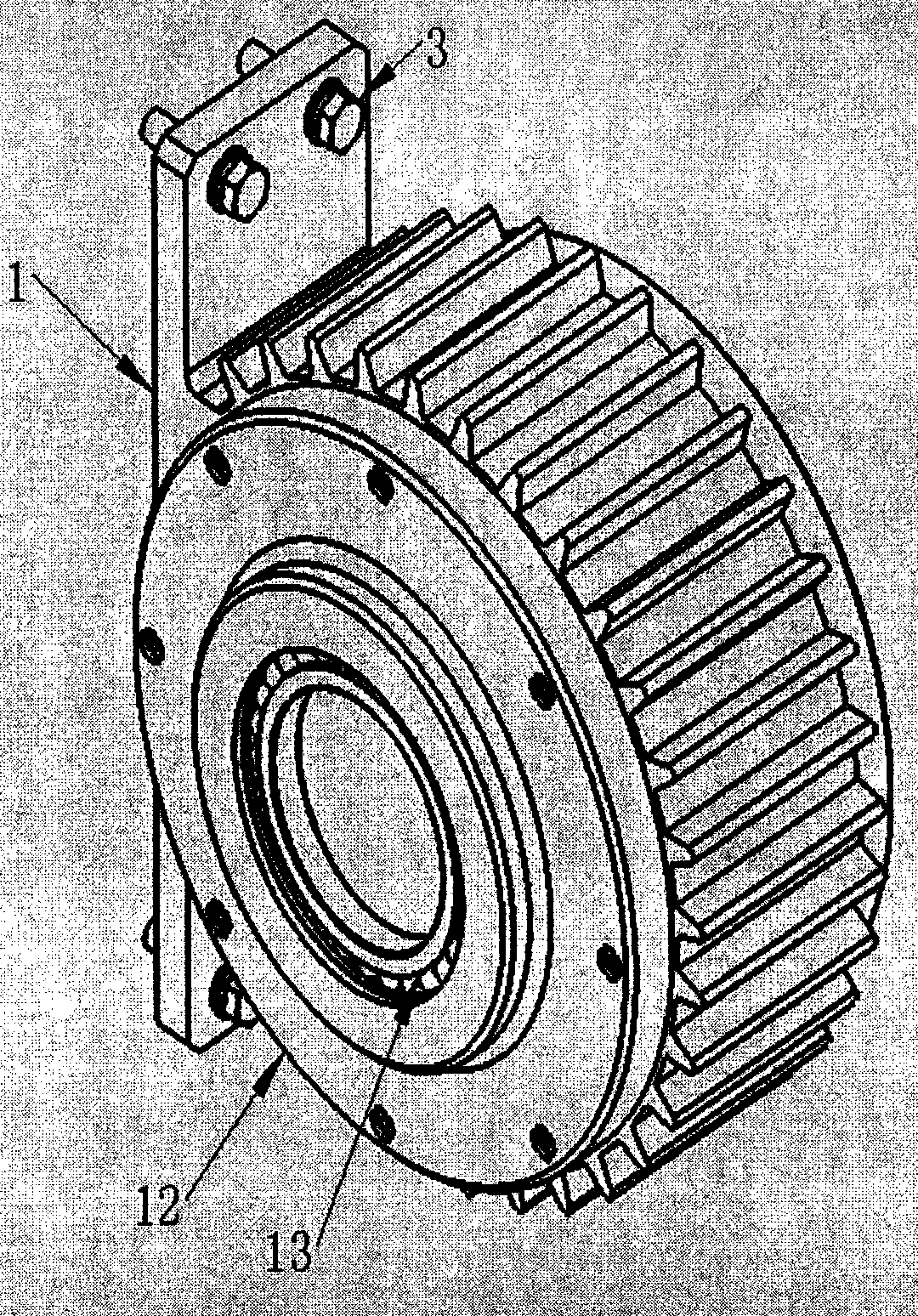

[0021] The retarder core of the present invention consists of a stator assembly ( figure 1 ), rotor assembly ( figure 2 ) and the stator body ( image 3 )composition. The main structure is a stator assembly clamped by two rotor assemblies.

[0022] In order to make the retarder of the present invention popularize quickly and be easy to install, the external structure of the retarder of the present invention is as consistent as possible with the existing retarder, see image 3 . Among the figure, 1 is a stator body, 3 is a retarder fixing screw, 12 is a stator body bearing cover, and 13 is a rolling bearing.

[0023] The rotor assembly of the core part of the retarder of the present invention is not a monolithic rotor disk, but a rotor disk inlaid with many permanent magnets; the rotor end disk of the retarder of the present invention is equipped with permanent magnets. figure 2 It is a structural schematic diagram of the left rotor assembly of the retarder of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com