Full-automatic feeding machine for marten breeding and control system thereof

A fully automatic feeding machine technology, applied in the field of feeding machines, can solve the problems of low feeding efficiency, environmental and noise pollution, and insufficient automation, and achieve the effects of high automation, improved accuracy, and improved breeding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

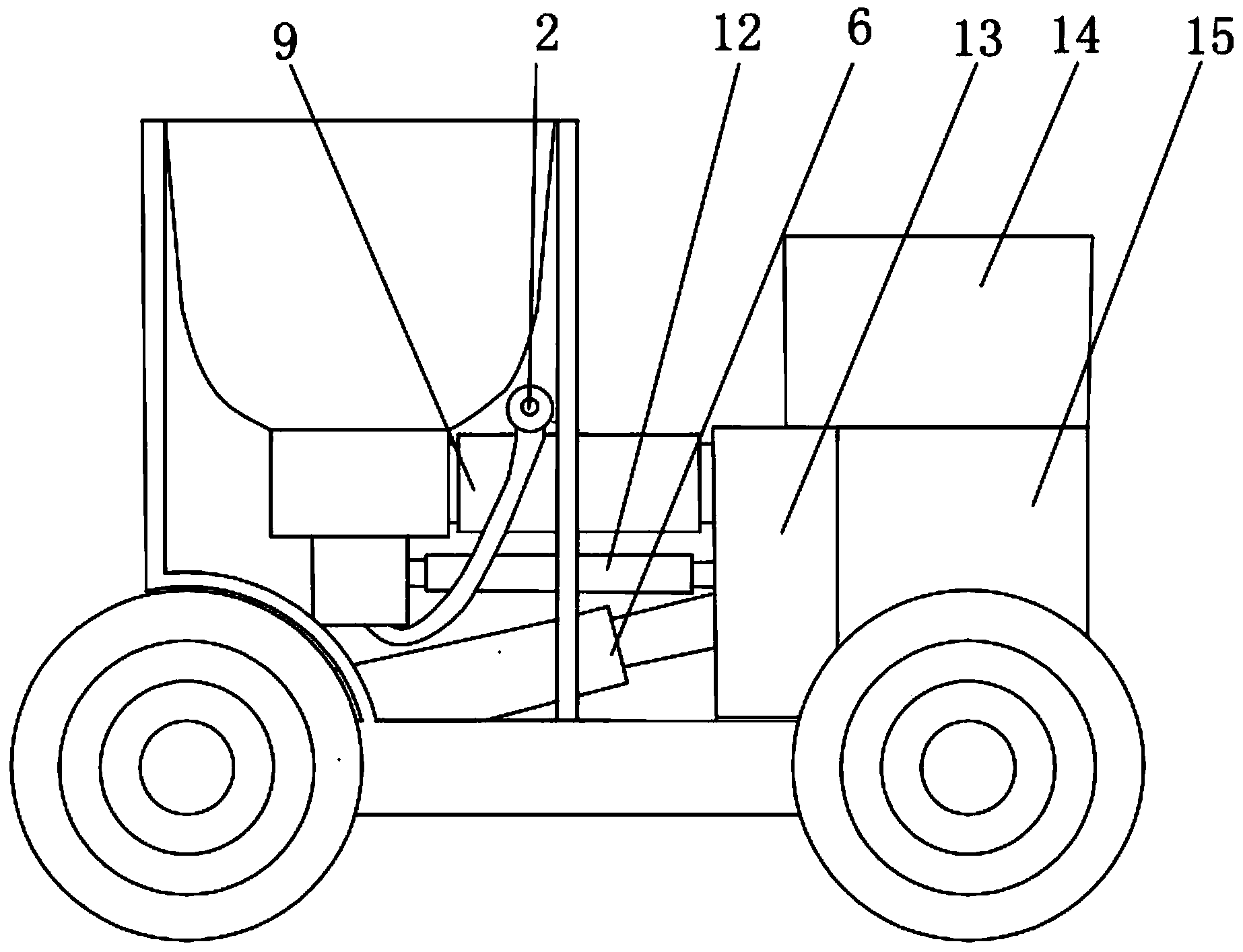

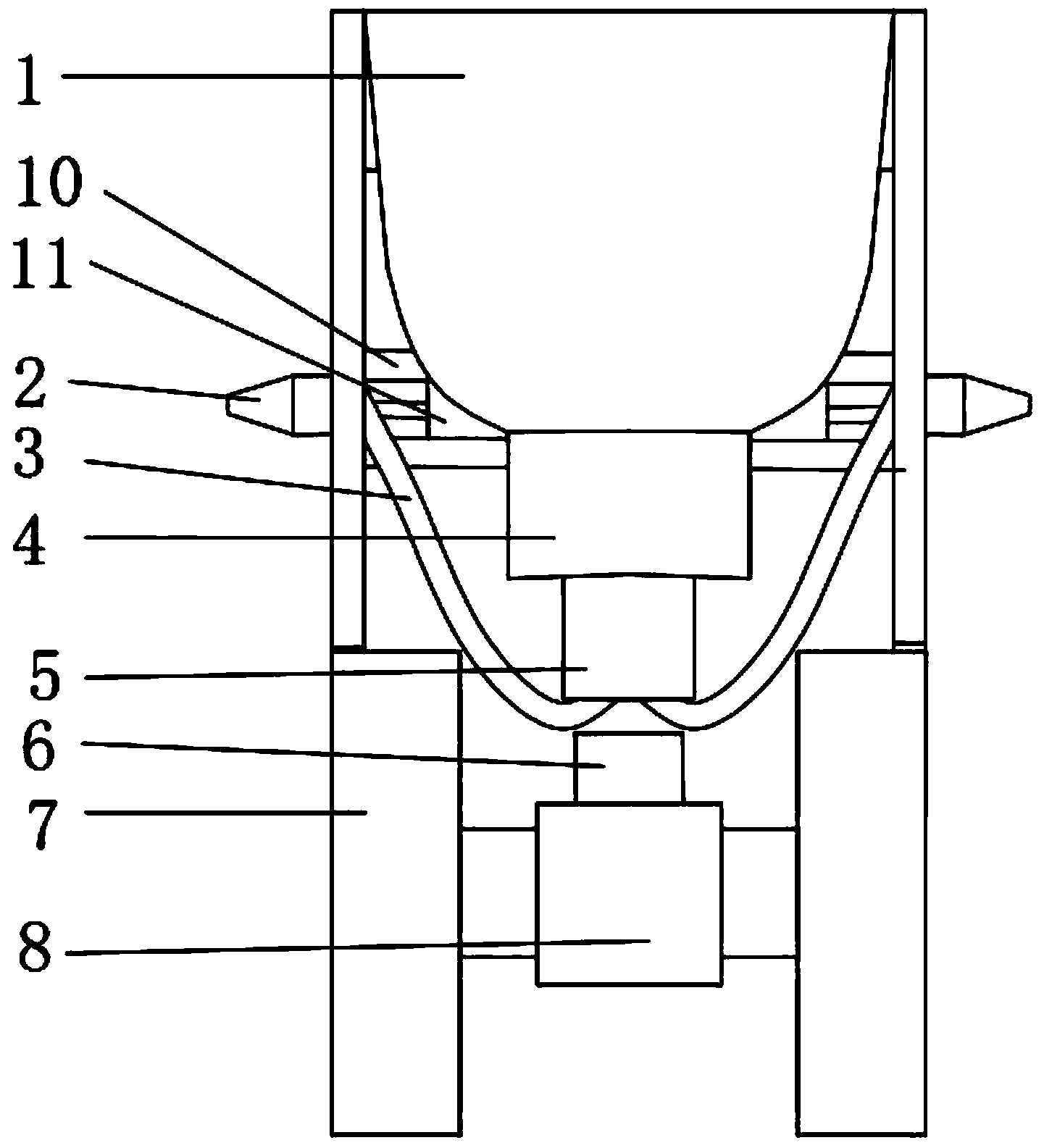

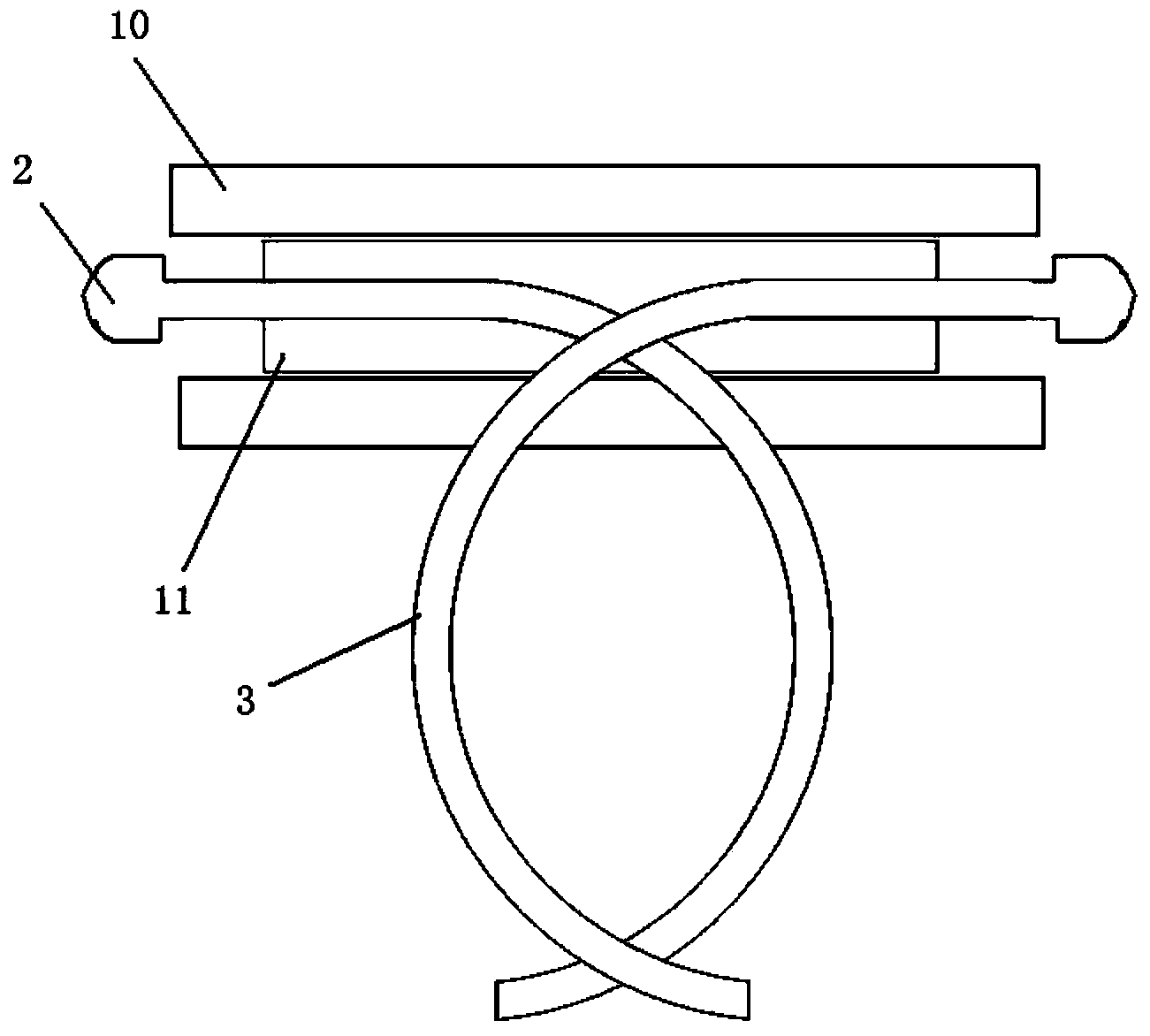

[0037] Embodiment one: if figure 1 , figure 2 , image 3 In the described embodiment, a kind of full-automatic mink feeding machine comprises feeding mechanism, vehicle frame 7, guide rail 10, pneumatic mechanism and control mechanism 14, and vehicle frame 7 is provided with driver 8, and feeding mechanism is installed on One end of the vehicle frame 7, the guide rail 10 is installed in the middle part of the vehicle frame 7, the pneumatic mechanism is installed on the other end of the vehicle frame 7, the feed mechanism is connected with the guide rail 10, and the driver 8 of the pneumatic mechanism and the feed mechanism and the vehicle frame 7 Connected, the control mechanism 14 is connected with the feeding mechanism and the pneumatic mechanism respectively.

[0038] The feeding mechanism includes a feed hopper 1, a distribution hopper 4, a feed hopper 5, a feed pipe 3 and several feed guns 2, the distribution hopper 4 is installed under the feed hopper 1, and the feed ...

Embodiment 2

[0053] Embodiment two: if figure 1 , figure 2 , image 3 In the described embodiment, a kind of full-automatic mink feeding machine comprises feeding mechanism, vehicle frame 7, guide rail 10, pneumatic mechanism and control mechanism 14, and vehicle frame 7 is provided with driver 8, and feeding mechanism is installed on One end of the vehicle frame 7, the guide rail 10 is installed in the middle part of the vehicle frame 7, the pneumatic mechanism is installed on the other end of the vehicle frame 7, the feed mechanism is connected with the guide rail 10, and the driver 8 of the pneumatic mechanism and the feed mechanism and the vehicle frame 7 Connected, the control mechanism 14 is connected with the feeding mechanism and the pneumatic mechanism respectively.

[0054] The feeding mechanism includes a feed hopper 1, a distribution hopper 4, a feed hopper 5, a feed pipe 3 and several feed guns 2, the distribution hopper 4 is installed under the feed hopper 1, and the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com