Vertical microwave photo-oxidative catalytic waste gas purifier

An exhaust gas purifier and microwave light technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of low humidity tolerance of exhaust gas, cumbersome replacement of lamps and other accessories, and high maintenance costs. The effect of reducing management difficulty and maintenance cost, continuously stabilizing exhaust gas purification effect, and simplifying maintenance management procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

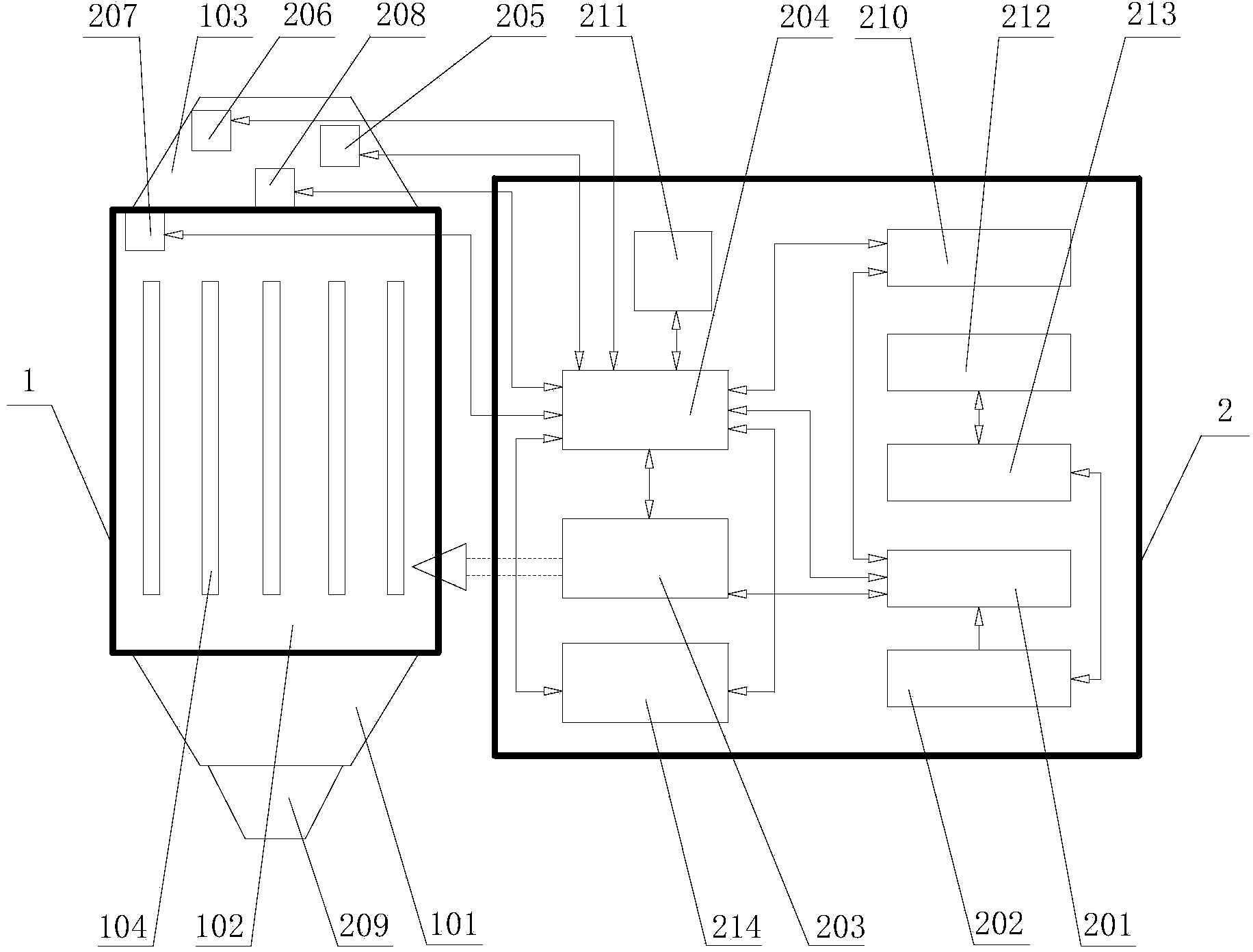

[0021] Example: see figure 1 , a vertical microwave photo-oxygen catalytic exhaust gas purifier, including a reaction unit 1 and a control unit 2, the control unit 2 includes an automatic control unit 2 of PLC204, a microwave generation unit 203, a waste water collection and discharge unit, an ozone detection unit, a VOC The detection unit and the fault self-inspection unit 211 also include a power supply module that provides energy for the purifier, and the reaction unit 1 includes an air inlet 101, a reaction chamber 102 and an exhaust port 103; the reaction chamber 102 is a built-in There is a vertical cavity with a lamp tube 104, its lower part is an air inlet 101, and the upper part is an air outlet 103, and the air inlet 101, the air outlet 103 and the reaction chamber 102 are on the same central axis; the ozone monitoring The unit 205 , the probe of the VOC monitoring unit 206 , and the waste water collection unit 209 are all set in the reaction unit 1 and connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com