Liquid injector

A liquid ejector and ejection port technology, which is applied to liquid ejection devices, ejection devices and other directions, can solve the problems of difficult control of range and ejection concentration, single function, inconvenient life, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

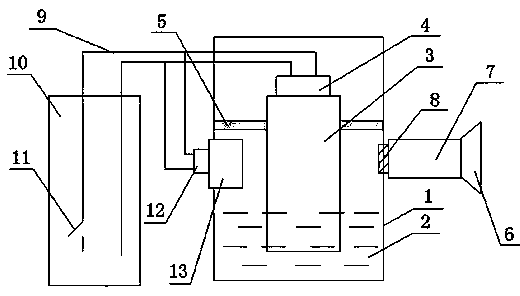

[0015] Accompanying drawing is the specific embodiment of the present invention.

[0016] Such as figure 1 The shown liquid injector of the present invention comprises a casing 1 and a liquid storage tank 2, an impeller 3 is arranged inside the casing 1, a motor A4 is installed on the upper end of the impeller 3, a protective layer 5 is arranged inside the casing 1, and an injection port 6 is arranged on one side of the casing 1. Port 6 is connected to liquid storage tank 2 through hose 7, gauze 8 is set at the joint between hose 7 and liquid storage tank 2, and described motor A4 is connected to main control room 10 through wire 9, and main control room 10 is provided with a regulator Speed switch 11.

[0017] The other side of the casing 1 is provided with a motor B12 and an accelerating fan 13, and the motor B12 is connected to the main control room 10 through a wire 9. Under the action of the accelerating fan 13, the ejected liquid has greater energy, a longer range, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com