Side frame assembling positioning mechanism of automatic laundry rack assembling system

An automatic assembly and positioning mechanism technology, applied in the direction of assembly machines, workpiece clamping devices, metal processing equipment, etc., can solve the problems of difficult positioning and fixing of side frames, poor practicability, unreasonable design, etc., and achieve mechanical automation control, Easy to locate and fix, and improve the effect of mechanical automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

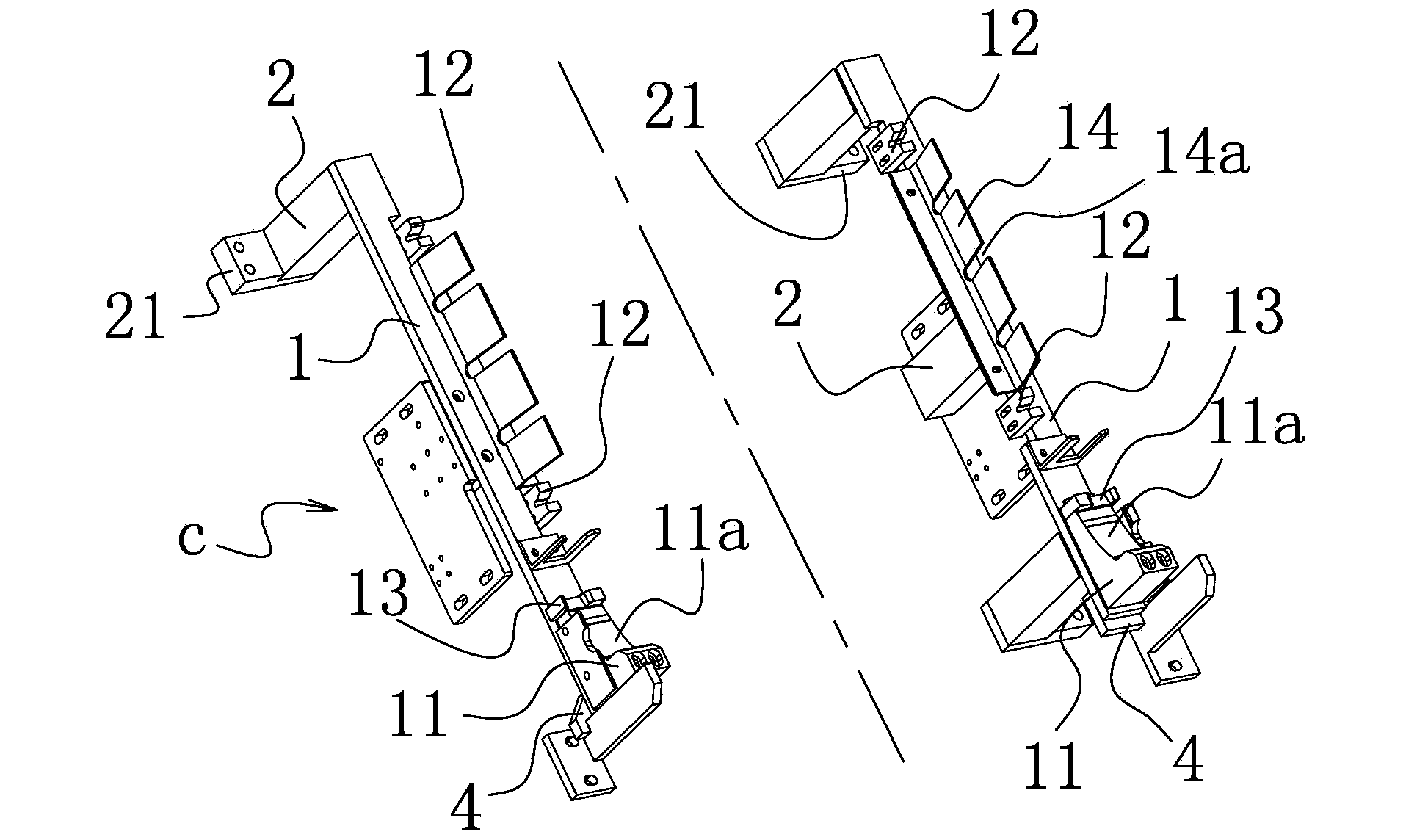

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

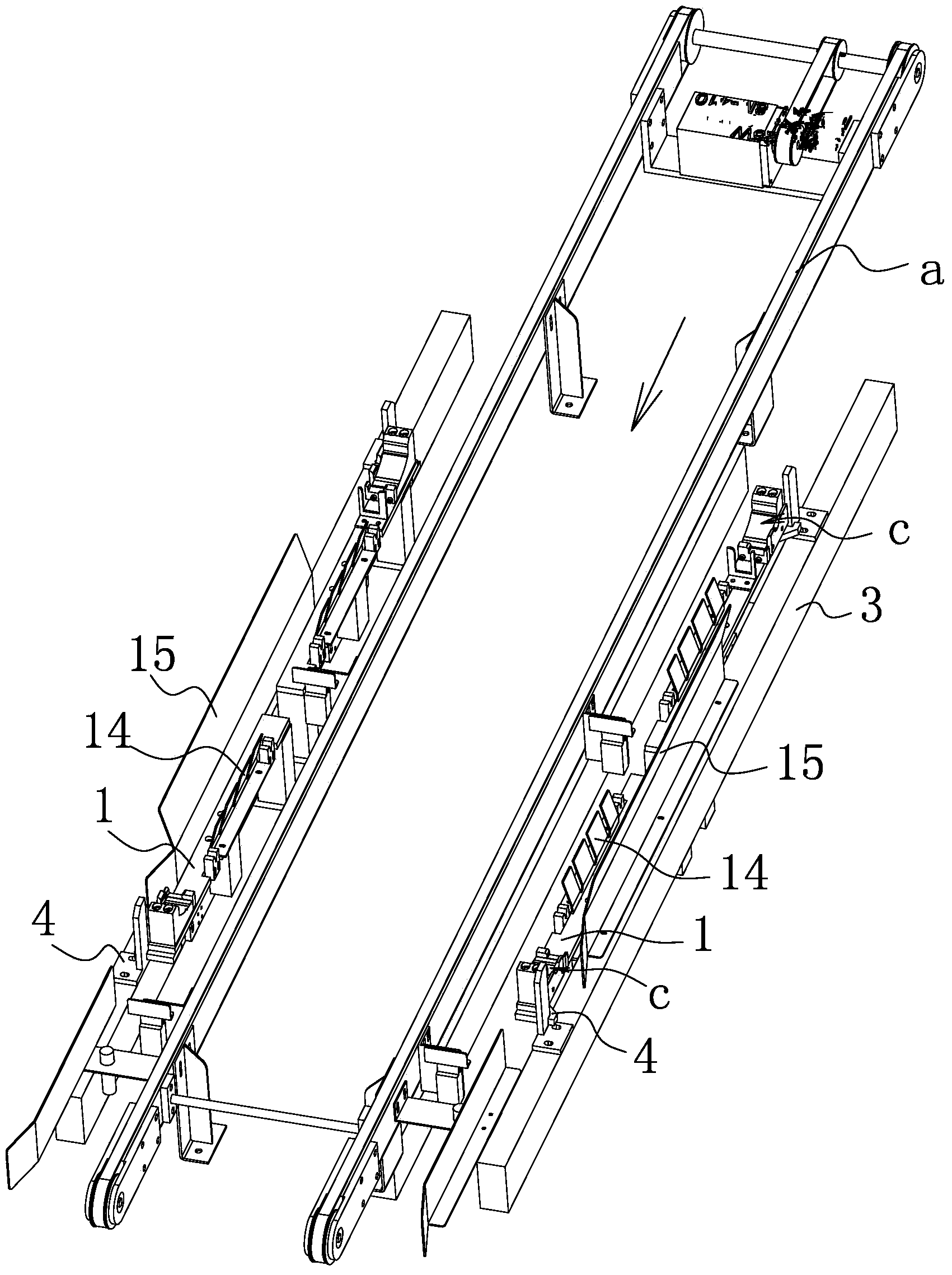

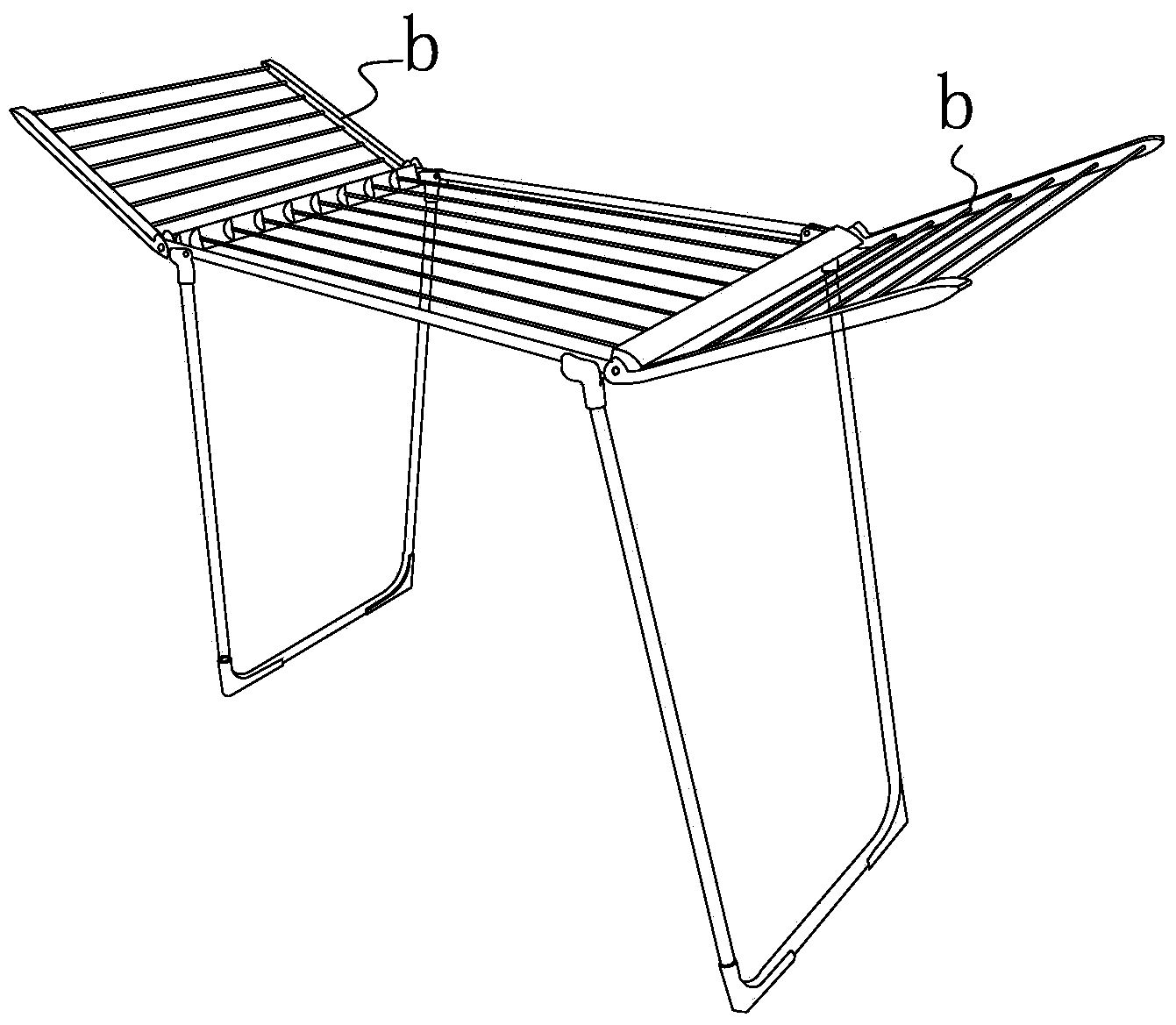

[0023] Such as Figure 1-3 As shown, the side frame assembly positioning mechanism of the clothes rack automatic assembly system, the clothes hanger automatic assembly system includes a frame 3, the frame 3 includes two corresponding installation arms 31, and the frame 3 is provided with a transmission belt c, The side frame assembly and positioning mechanism includes side frame positioning tooling c which are respectively arranged on the frame 3 and can be lifted in the vertical direction.

[0024] The installation of two side frame positioning fixtures can improve production efficiency, and at the same time, combined with the liftable structure, the degree of mechanical automation can be further improved. At the same time, it is also convenient for the positioning and fixing of the side frames. , and then fix the side frames b to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap