Trailer plate and work method thereof

A working method and the technology of the trailer board, which are applied in the direction of motor vehicles, goods transport vehicles, vehicles used for freight transportation, etc., can solve the problems of high difficulty, large size of wrecker trailers, and long time for dispatching trailers, etc., and achieve a compact overall , The effect of balancing local pressure and facilitating storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

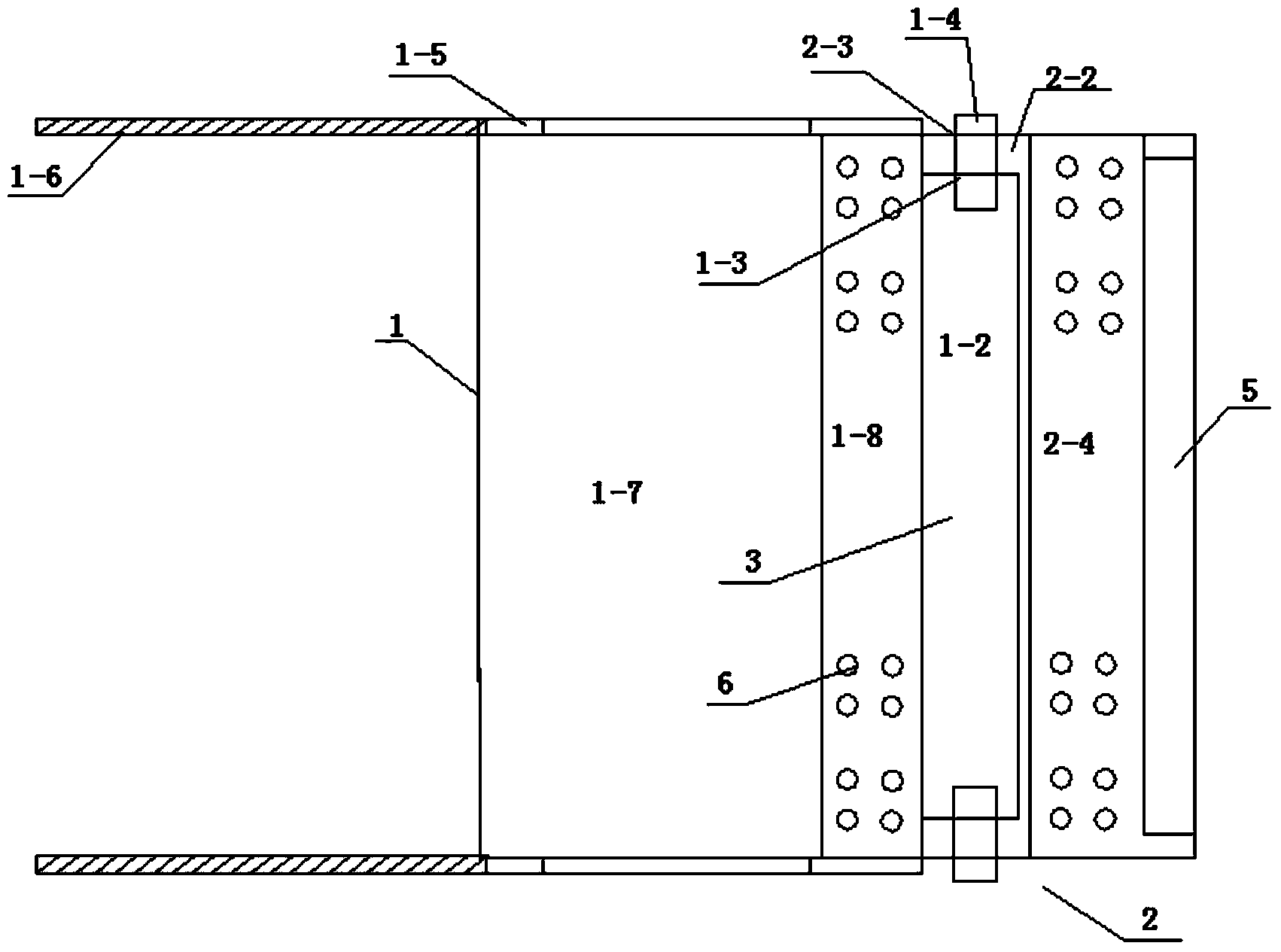

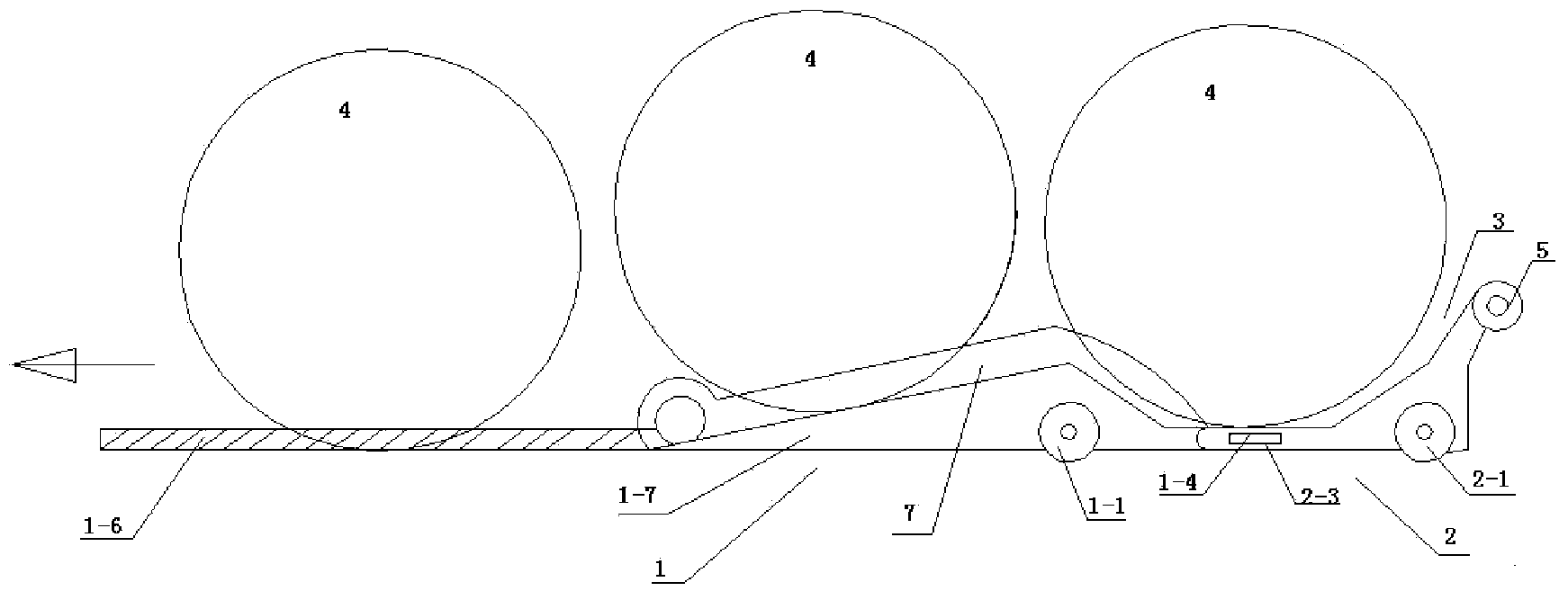

[0040] A trailer board, comprising a wheel guide plate 1, a wheel stop plate 2 connected to the rear of the wheel guide plate 1, a front small wheel 1-1 is arranged at the bottom of the wheel guide plate 1, and a small front wheel 1-1 is arranged at the rear of the wheel guide plate 1 The bottom of the plate 2 is provided with a rear small wheel 2-1; the rear part of the wheel guide plate 1 is provided with a first connecting piece 1-2, and the front part of the wheel stop plate 2 is provided with a second connecting piece 2- 2. A first rectangular connecting hole 1-3 is hollowed out on the first connecting piece 1-2, and a second rectangular connecting hole 2-3 is hollowed out on the second connecting piece 2-2. The first rectangular connecting hole 1-3 and the second rectangular connecting hole 2-3 are provided with a rectangular pin 1-4 adapted to the shape of the rectangular connecting hole; the first rectangular connecting hole 1-3 and the second rectangular connecting hol...

Embodiment 2

[0045] According to the trailer board described in Embodiment 1, the difference lies in that a horizontal handle 5 is provided at the rear end of the wheel stop board 2 .

Embodiment 3

[0047] A kind of working method that utilizes trailer board as described in embodiment 1, comprises trailer working method:

[0048] 1) The wheel guide plate 1 and the wheel stop plate 2 of the trailer plate are fixedly connected by rectangular pins 1-4;

[0049] 2) Select the braked front wheel or the braked rear wheel of the vehicle to be towed, and place the front end of the trailer plate behind the braked front wheel or the braked rear wheel;

[0050] 3) The front end of the wheel guide plate 1 is opposite to the junction of the wheel 4 and the ground, a staff member pulls the traction rope 1-6 in front of the trailer board, and another staff member pulls the traction rope 1-6 by holding the lying handle 5 to ensure that the braked front wheel or the braked rear wheel rolls into the concave arc wheel groove 3 along the wheel guide plate;

[0051] 4) Realize the movement of the vehicle by pulling the traction rope 1-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com