An instant weighing high-speed forklift

A high-speed, forklift technology, applied in the direction of lifting devices, etc., can solve the problems of forklifts without load-bearing function, high maintenance cost, slow down work efficiency, etc., achieve the effect of simple structure, low maintenance cost, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

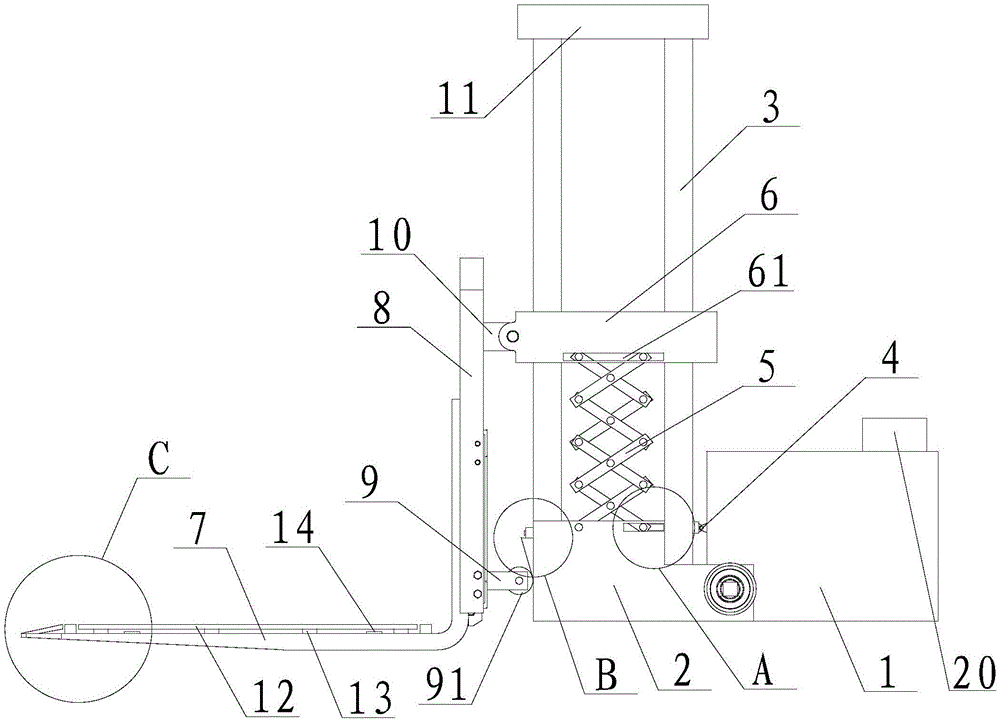

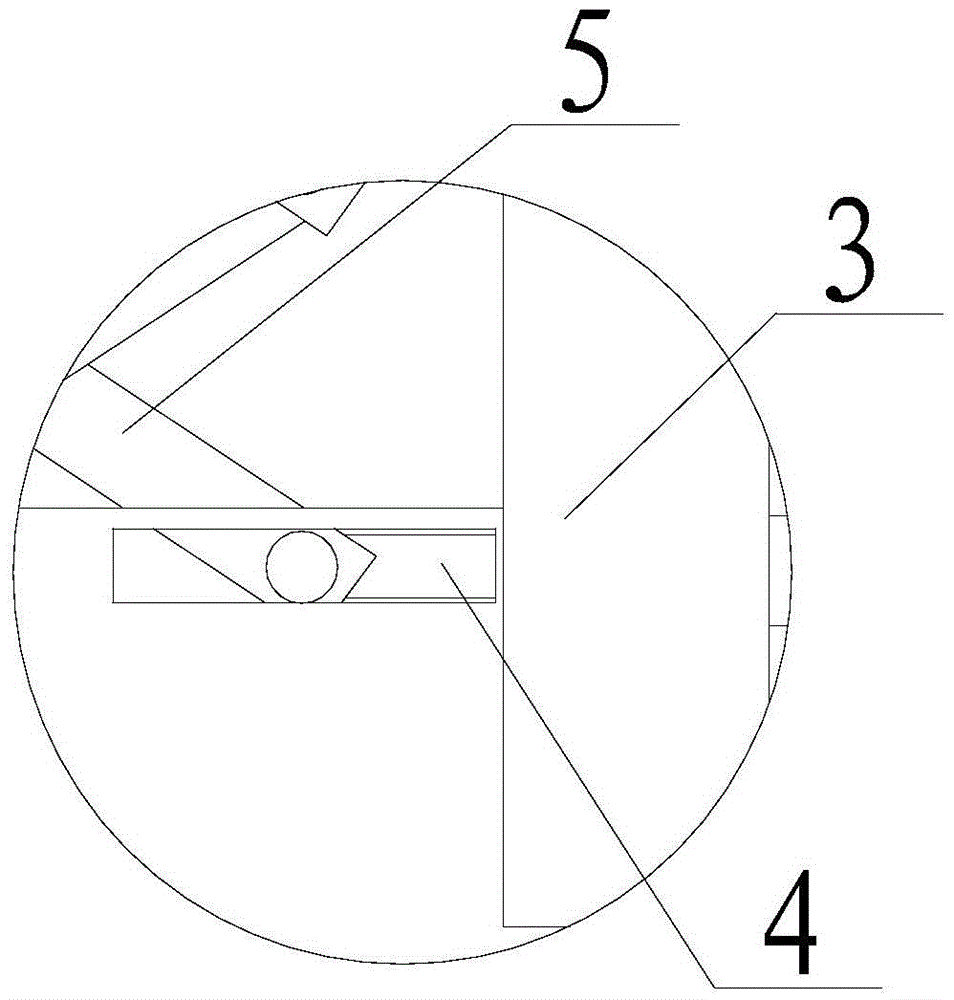

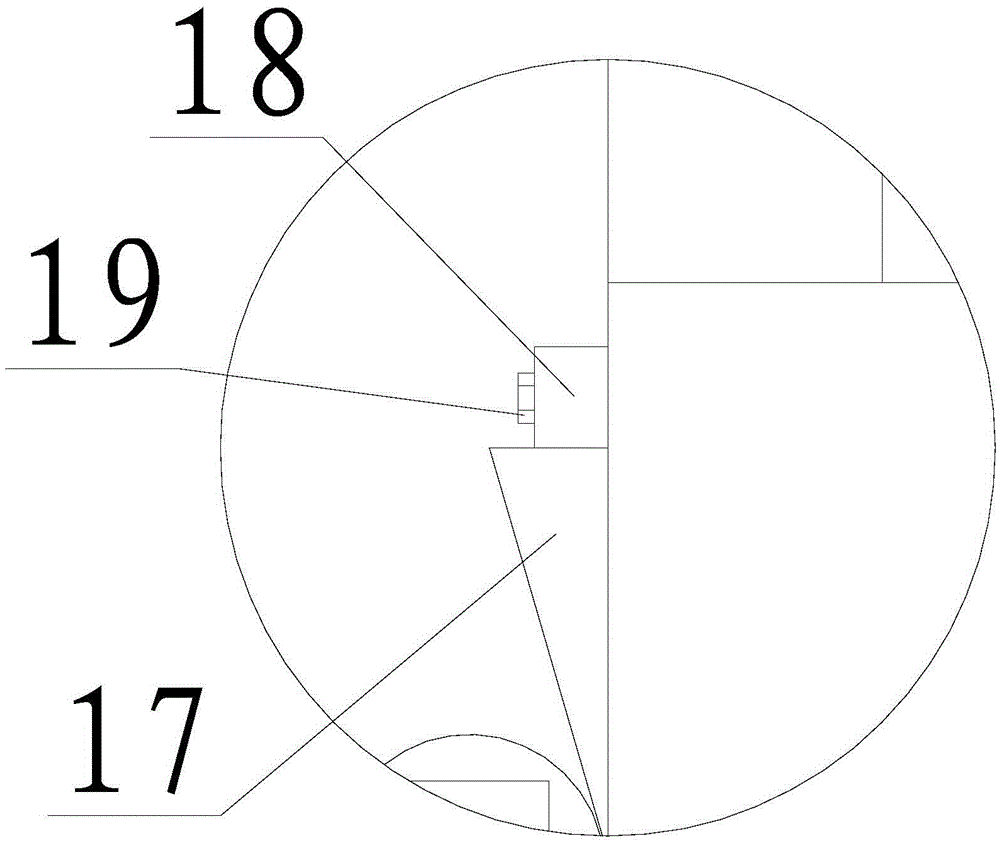

[0020] refer to figure 1 , figure 2 , image 3 with Figure 4 , the present invention is an instant weighing high-speed forklift, including guide rod 3, lifting hydraulic cylinder 4, folding lifting platform 5, lifting platform 6, vehicle body 1, weighing plate 12, fork base 2, pressure sensor 13, control 20, level sensor 14, level adjustment block 17, fork foot 7 and fork foot seat 8, the vehicle body 1 is fixedly connected with the fork seat 2, and several guide rods 3 are arranged on the fork seat 2, and the guide rod 3 A folding lifting platform 5 is arranged between them, and a lifting hydraulic cylinder 4 is hingedly installed on the vehicle body 1. , the lifting table 6 is connected with the fork foot seat 8, the fork foot 7 is installed on the fork foot seat 8, a plurality of pressure sensors 13 are arranged on the fork foot 7, and a weighing plate is arranged on the pressure sensor 13 12. A level sensor 14 is installed on the lower part of the weighing plate 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com