A kind of nitrogen protection iron ditch and its nitrogen protection method

A nitrogen protection, iron groove technology, applied in furnaces, discharge devices, lighting and heating equipment, etc., can solve the problem of increasing the corrosion degree of iron grooves, and achieve the effect of delaying oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

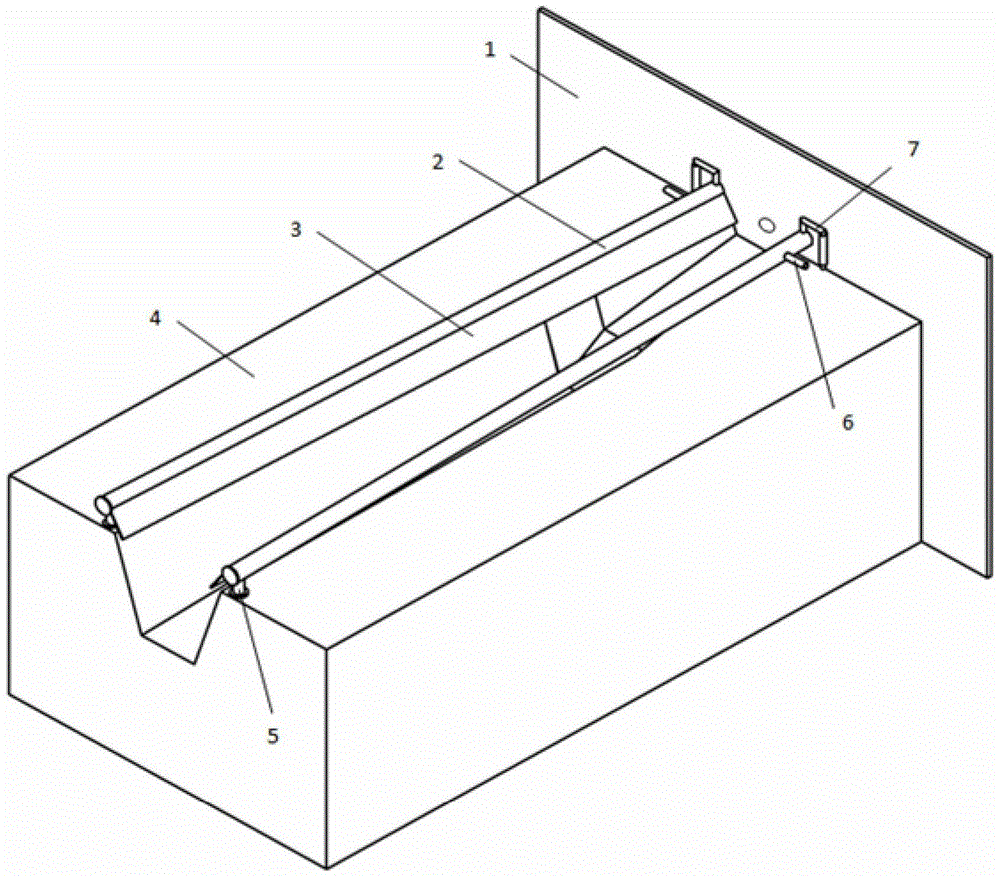

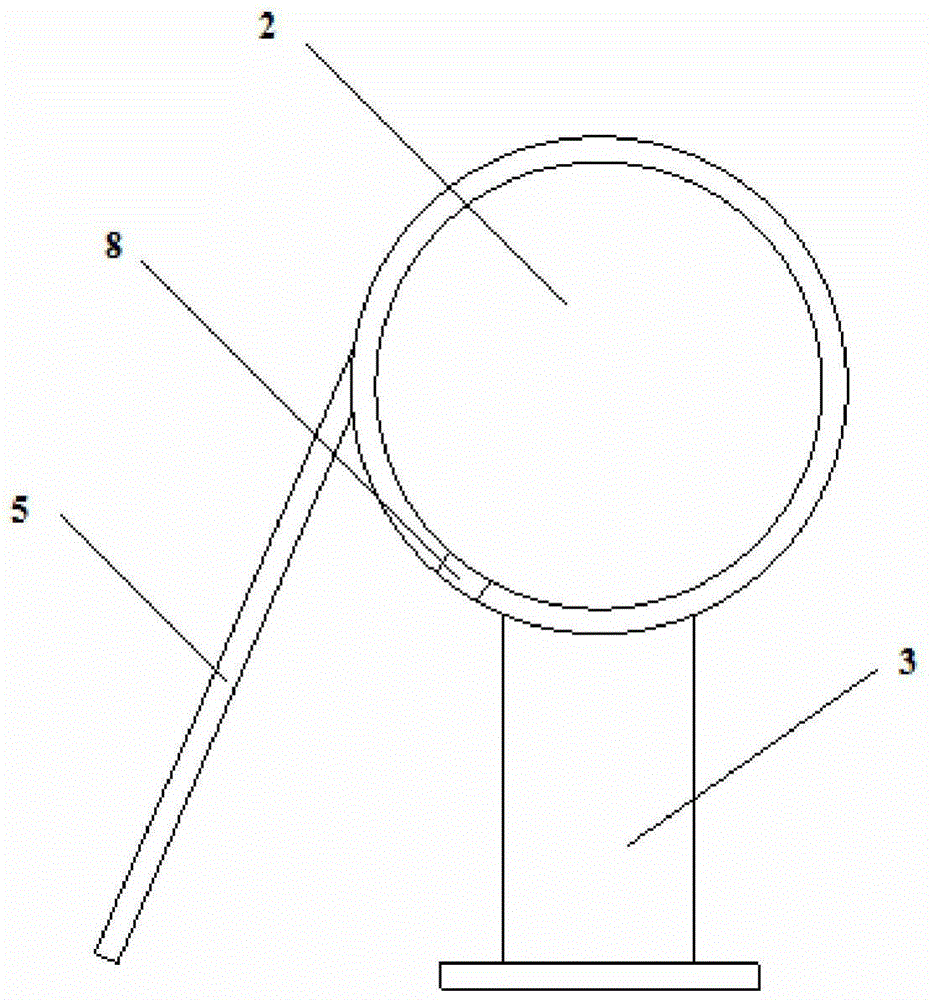

[0030] Such as figure 1 A nitrogen-protected iron trough is shown, including the main body of the iron trough and a pipeline gas injection device. The pipeline gas injection device includes a gas transmission pipeline 2, a gas transmission pipeline fixing mechanism, and a gas guiding mechanism; wherein: both sides of the trench wall of the iron trough main body Gas pipelines 2 are respectively arranged along the direction of the ditch; the outside of each gas pipeline is provided with an intake pipe 6, and the pipeline cross-sectional view (support end) of the nitrogen protection iron ditch is as follows: figure 2 As shown, each gas pipeline 2 is provided with an air curtain forming part near the bottom side; the air inlet end of the gas pipeline 2 is connected with the blast furnace shell 1 through a hinge 7, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com