A pneumatic motor with screw drive

A pneumatic engine and screw rod technology, applied in the direction of machines/engines, intermeshing engines, mechanisms for generating mechanical power, etc., can solve problems such as low energy utilization rate, low output power, and temperature drop, and improve energy utilization efficiency , Improve the effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

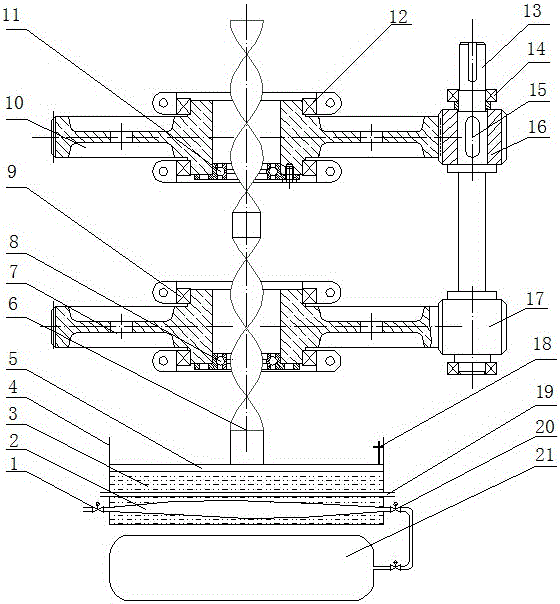

[0030] Such as Figure 1~3 as shown,

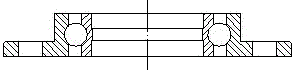

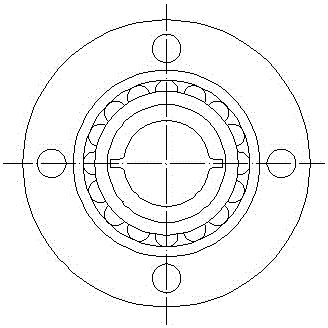

[0031] A pneumatic engine adopting screw rod transmission, including an air storage tank 21, an expansion air bag 2, a cylinder 4, a piston 5, a heat exchange fluid 3, a bearing, a gear, a screw rod 6, and an output shaft 13; the inside of the cylinder 4 is provided with The expansion air bag 2 and the cylinder 4 are equipped with heat exchange fluid 3, the expansion air bag 2 is located between the heat exchange liquid 3, the piston 5 is arranged above the heat exchange liquid 3, the center of the piston 5 is connected to the screw rod 6, and the two ends of the screw rod 6 The spiral direction is opposite, the lower end of the screw rod 6 is provided with a first one-way bearing 8, the upper end of the screw rod 6 is provided with a second one-way bearing 11, and the left end of the first one-way bearing 8 is connected to the first gear 7, and the first gear 7 is connected to the first gear 7. A pair of ball bearings 9 are positioned i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com