Rivet structure for spacer sleeve on cross-section-variable nozzle ring of turbocharger

A turbocharger and riveting structure technology, applied in the direction of stator, machine/engine, engine components, etc., can solve the problems of insufficient strength of riveting points, cracking of riveting parts, low strength of riveting points, etc., to improve mechanical properties And the reliability of use, increase the stress area, and the effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

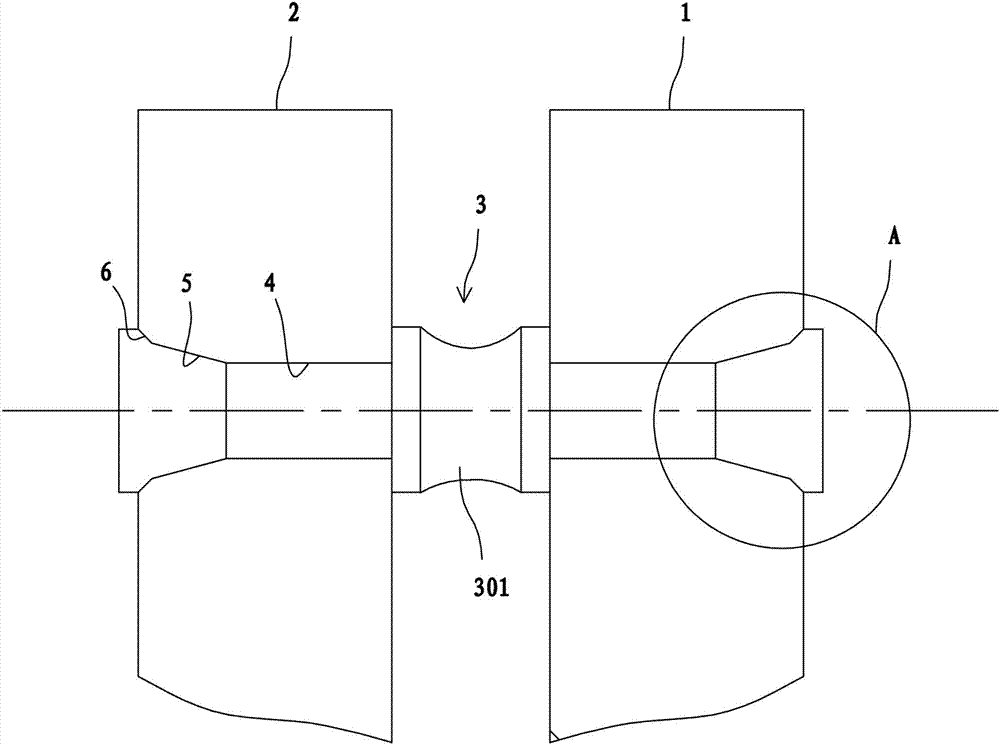

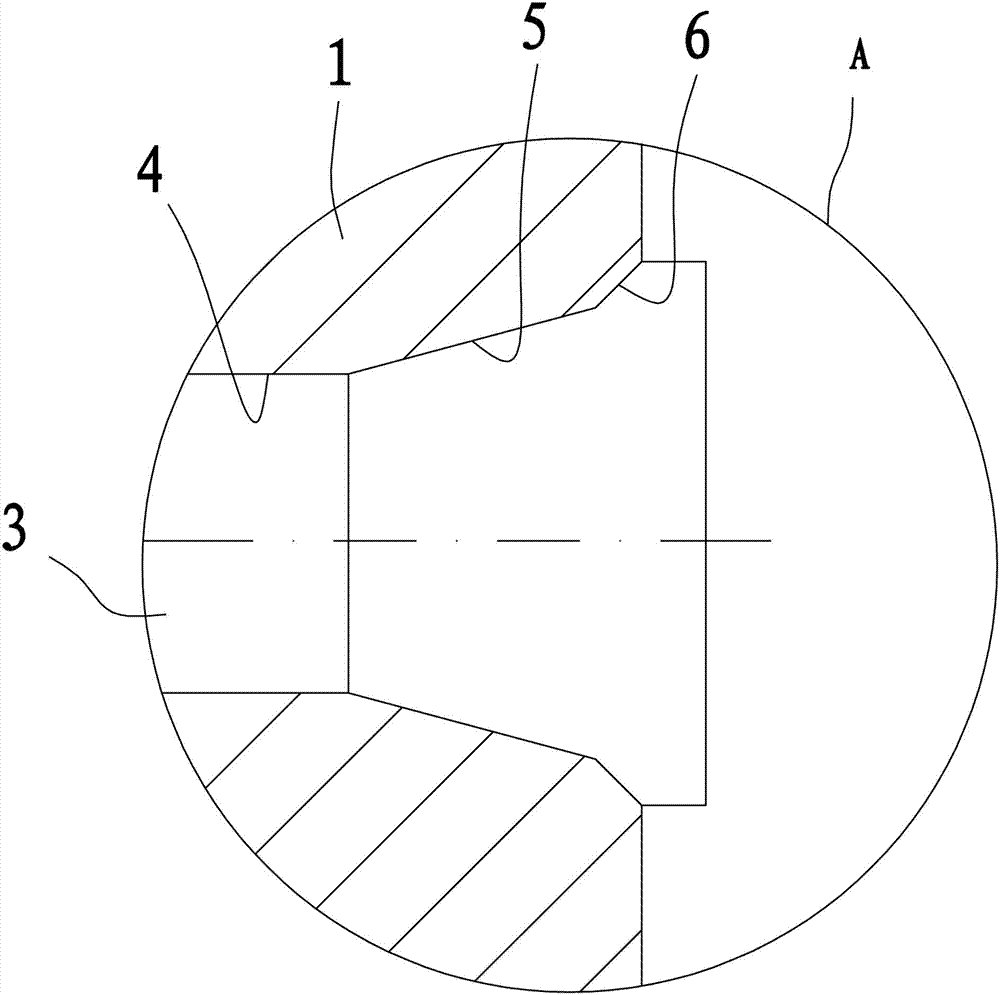

[0019] Depend on figure 1 , figure 2 As shown, the present invention is used for the riveting structure of the spacer sleeve on the variable section nozzle ring of the turbocharger, which includes a first workpiece 1, a second workpiece 2 and a riveting part 3.

[0020] The first workpiece 1 is provided with a first through hole.

[0021] The second workpiece 2 is provided with a second through hole coaxial with the first through hole.

[0022] The riveting part 3 is pierced and riveted and fixed in the first through hole and the second through hole. The riveting part 3 is sleeved and fixed with a distance sleeve 301, and the distance sleeve 301 is arranged on the first workpiece 1. Between the distance sleeve 301 and the second workpiece 2 , the two ends of the distance sleeve 301 abut against the two adjacent surfaces of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com