Improved environment-friendly and energy-saving stove

An environmentally friendly, energy-saving, combustion board technology, which is applied to household stoves/stoves, household heating, lighting and heating equipment, etc., can solve problems such as concentrated firepower, inaccurate dimensions, tempering, flame loss and fire failure, and achieve effective energy The effect of improved conversion, reasonable size design and precise ignition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

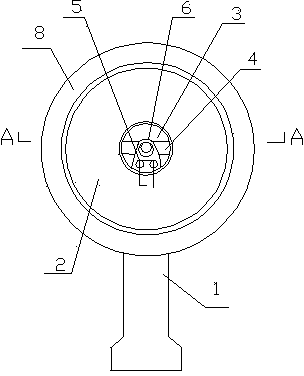

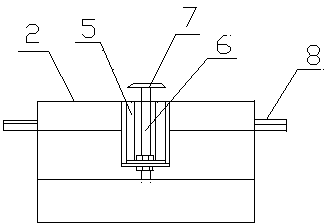

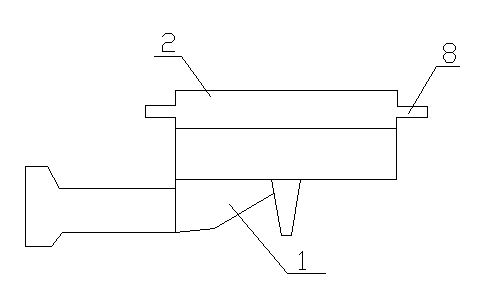

[0024] like figure 1 , 2 , 3, the environment-friendly and energy-saving stove includes a combustion plate 2 with a base located on the base 1, and an ignition hole 3 located at the center of the combustion plate 2, the base 1 is a hollow cast iron body, and the combustion plate 2 is a non-metal mesh hexagonal circle Hole type, the diameter of the combustion plate is 112mm, the diameter of the ignition hole 3 located in the center of the combustion plate 2 is 35mm, the depth of the ignition hole 3 is 13mm, a beam 4 is arranged at the bottom of the ignition hole 3, and a double magnetic ignition needle is fixed on the beam 4 Type ignition device 5, the ignition device 5 is fixed on the beam 4 in the ignition hole 3 through the screw rod 6, the double magnetic ignition needle protrudes from the ignition hole 3 and is located on the combustion plate surface, the upper end of the screw rod 6 protrudes from the plane of the combustion plate 2, and the screw rod 6 The upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com