Anti-slip anti-shaking constant pressure type cable meter counting device

A meter counting device and cable technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of different tension measurement results, the pressure wheel can not perform the pressing effect, and affects the measurement accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

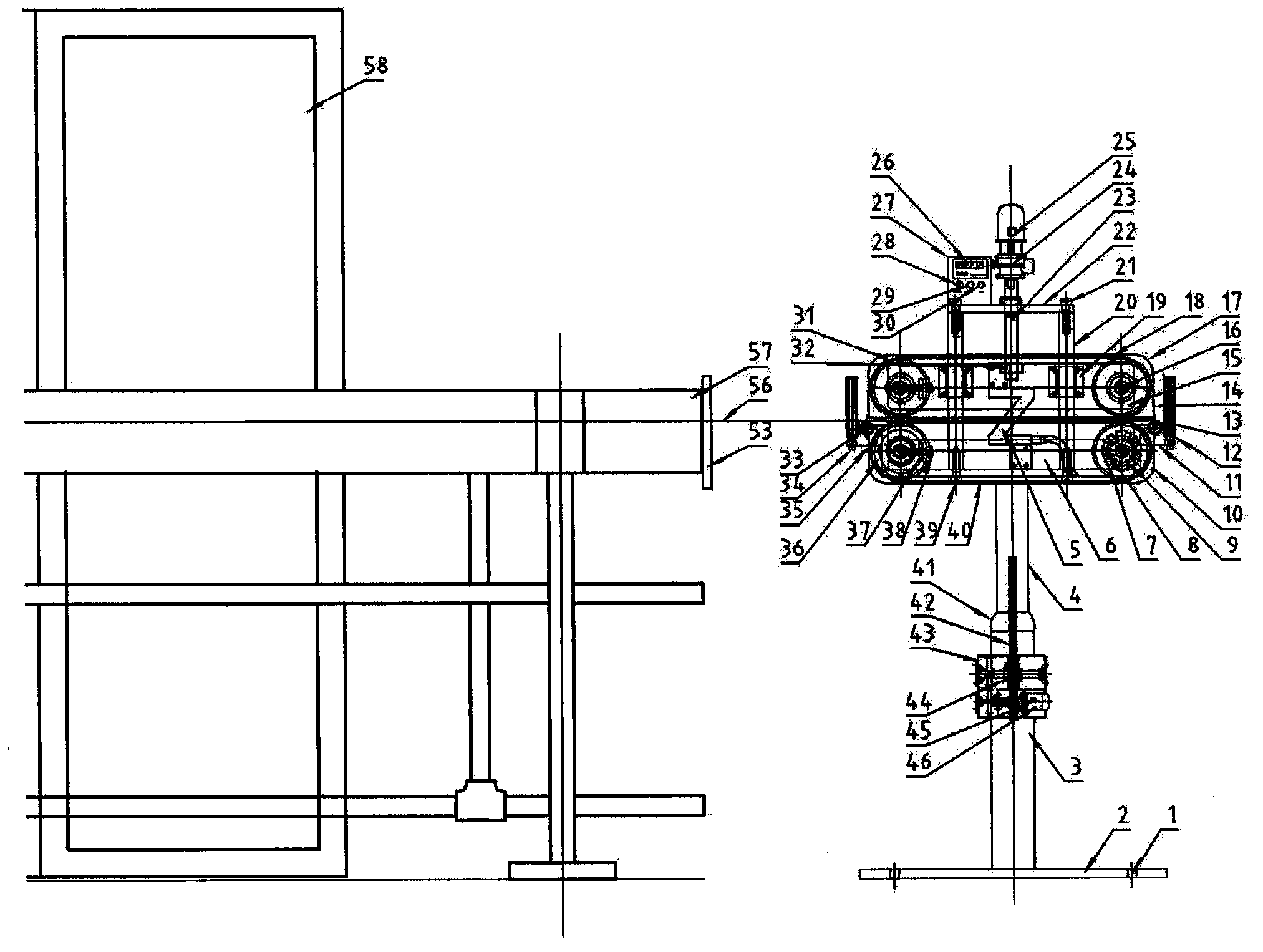

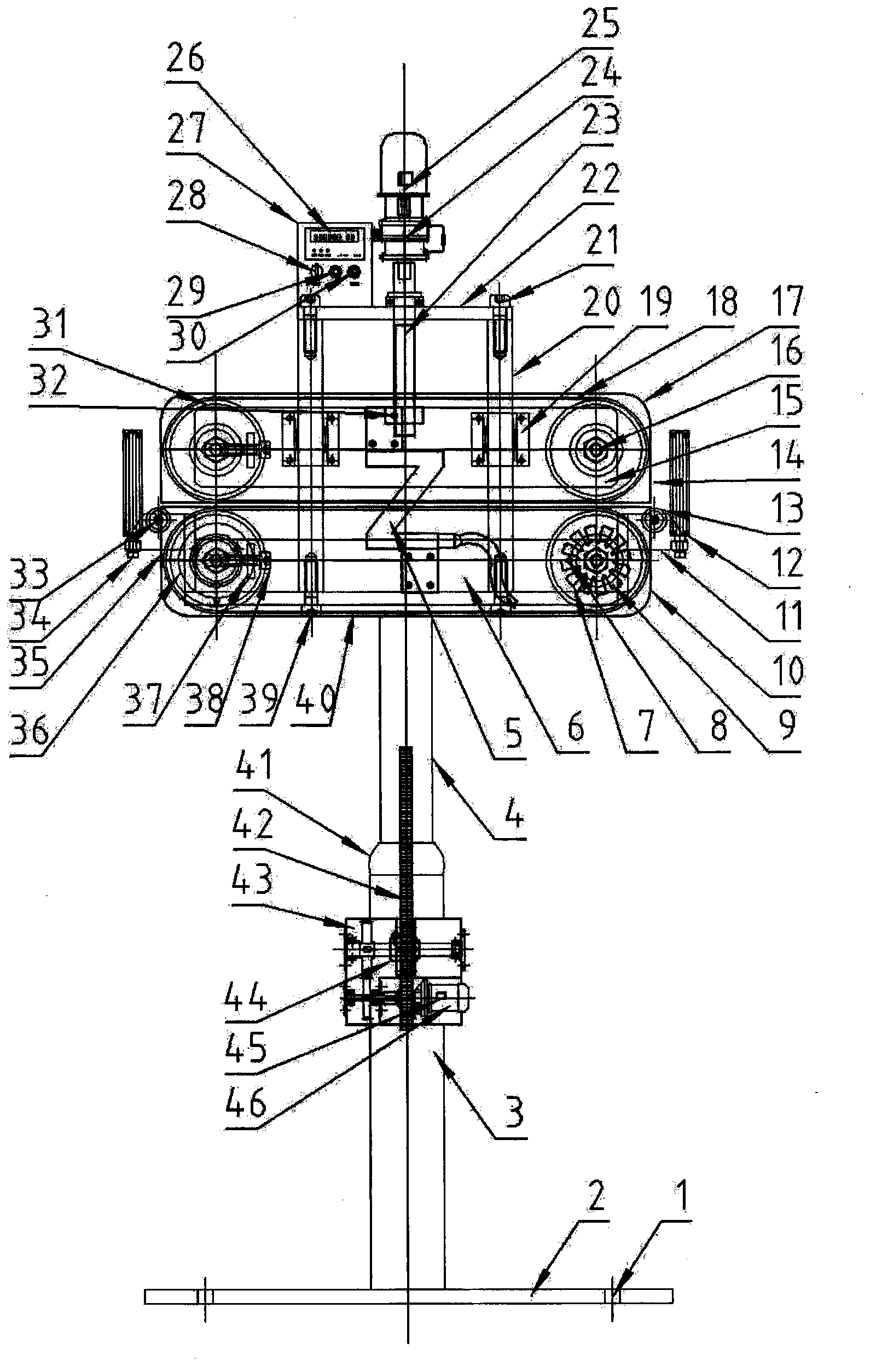

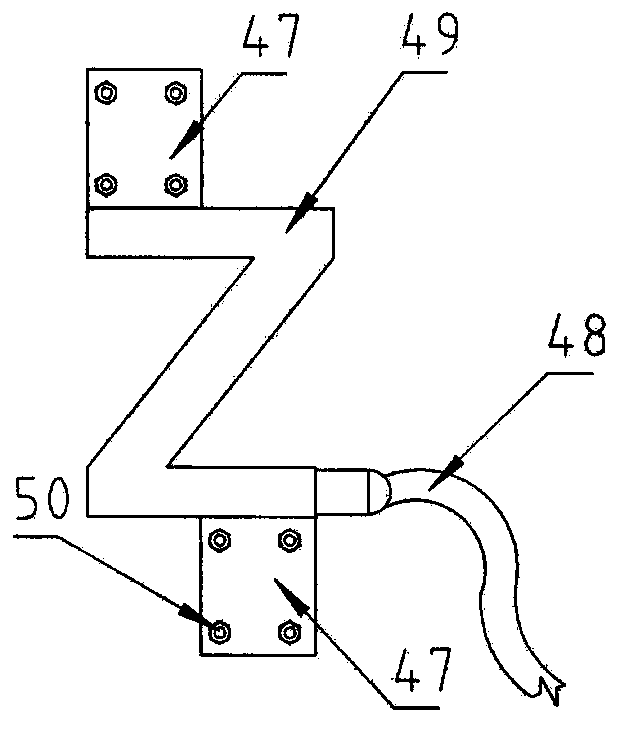

[0017] see figure 1 and figure 2 , an anti-skid and anti-shake constant pressure cable meter meter device, which includes a host 57, a power distribution cabinet 58 is installed on the host 57, and the host 57 is also equipped with the center of the height from the ground when the cable 56 passes automatically. A point detection photoelectric sensor 53, a base 2 is arranged next to the host machine 57, a column 3 is fixed on the base 2, a movable column 4 is installed on the column 3, a fixed support 6 at the lower end is fixed on the movable column 4, and the center point detection photoelectric sensor 53 drives the center height by command Gearbox 43, the center height gearbox 43 rotates the center height adjustment servo motor 46, the center height adjustment servo motor 46 drives the rack 42, the rack 42 moves the movable column 4 up and down, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com