Portable film processor

A film processor, a portable technology, applied in optics, instruments, liquid processing equipment, etc., can solve the problem that the semi-automatic film processor does not have the film drying function, the semi-automatic film processor, the incomplete function of washing film, and the automatic film processor. It has the function of film viewing and other problems, so as to increase the practicality, shorten the processing time, and facilitate the field transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

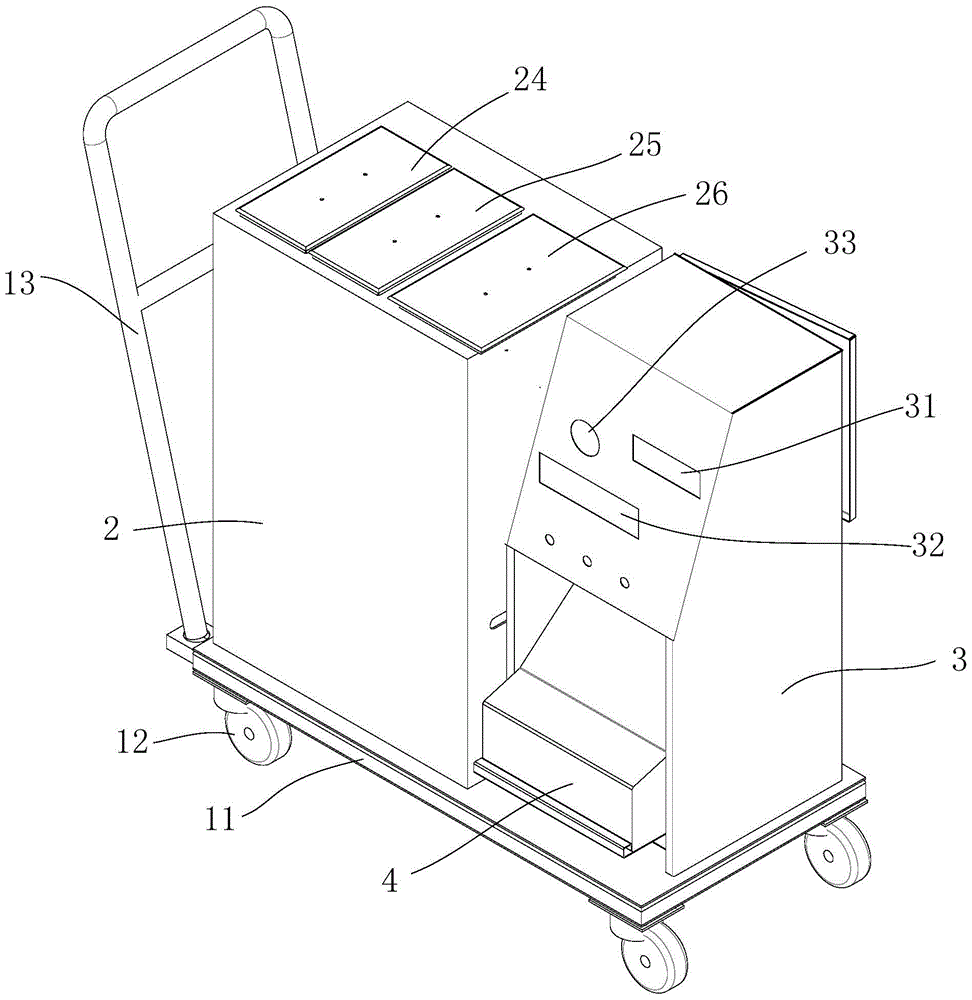

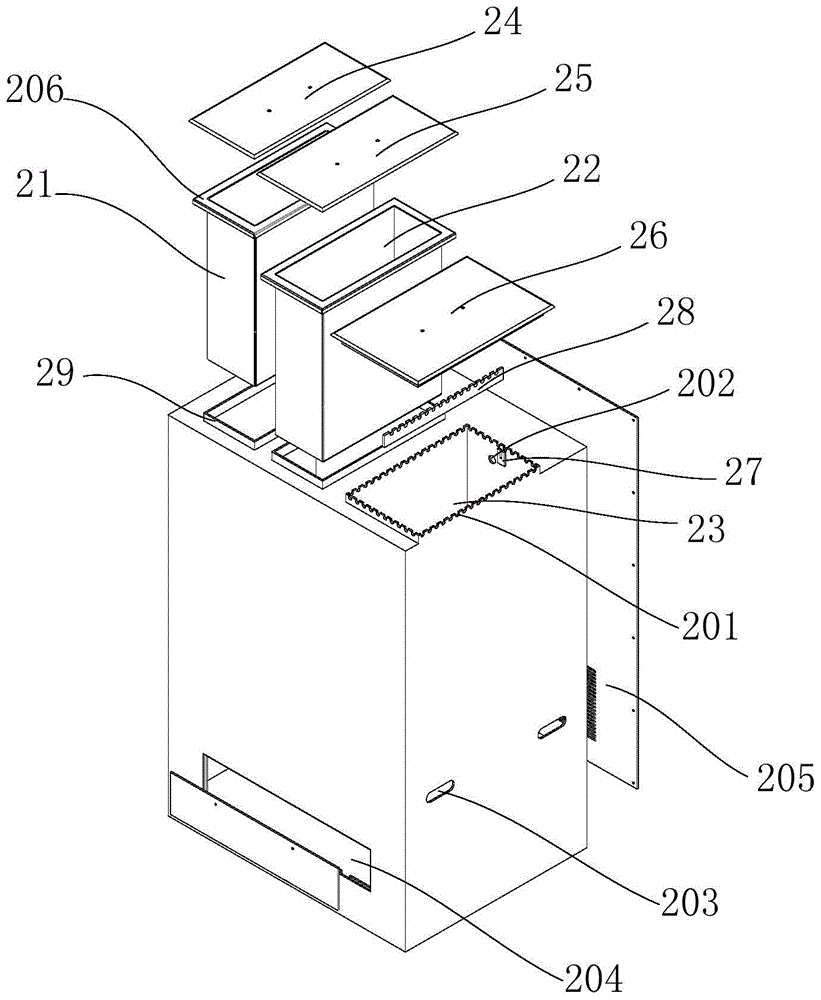

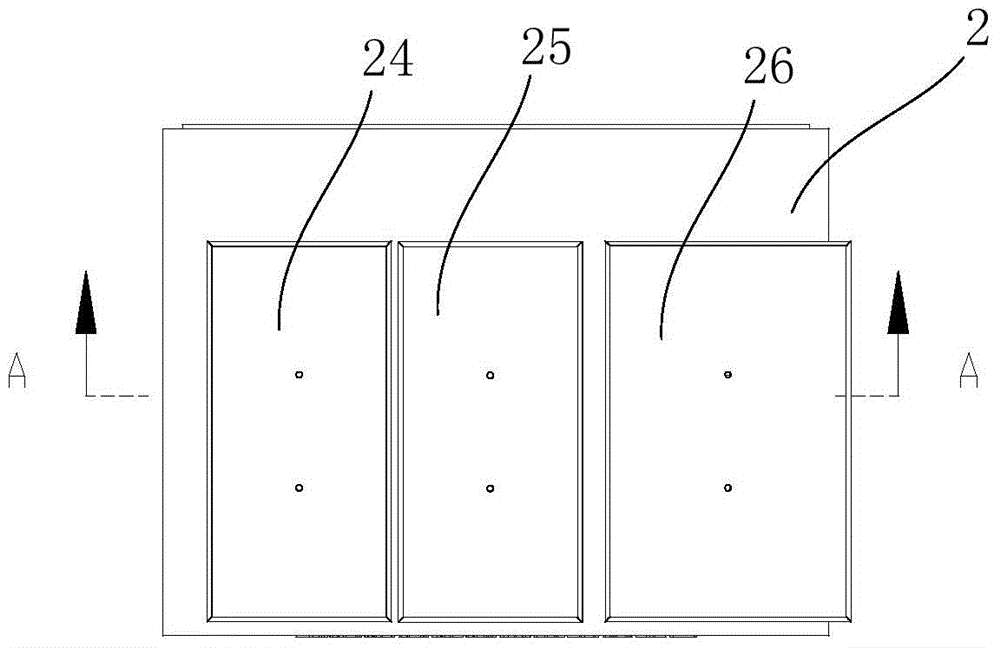

[0056] Such as Figure 1 to Figure 4As shown, the present invention provides a portable film processor, comprising a film processor 2, a film dryer 4, a control cabinet 3 and a carrying trolley, and the film processor 2, the film dryer 4, and the control cabinet 3 are detachably installed on the carrier On the trolley, the carrying trolley includes a base 11, a hand push rod 13 installed on the base 11, and a roller 12 installed below the base 11. The base 11 is provided with a film developing host installation groove and a control cabinet installation groove, and the film developing host 2 is installed. In the installation groove of the film developing host, the control cabinet 3 is installed in the control cabinet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com