Anticorona flange for extra-high voltage post insulator

A pillar insulator, anti-corona technology, applied in the direction of supporting insulators, insulators, circuits, etc., can solve the problems of stress on the porcelain body, poor sealing of the flange, and deterioration of the colloidal layer, and achieves excellent oxidation effect. The effect of ensuring safe use and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

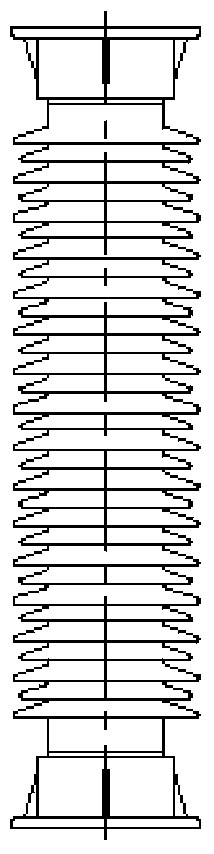

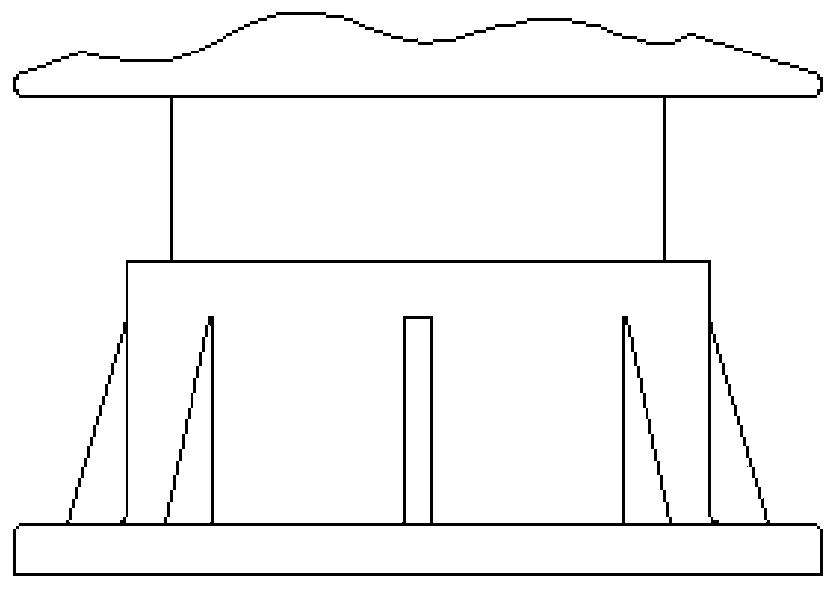

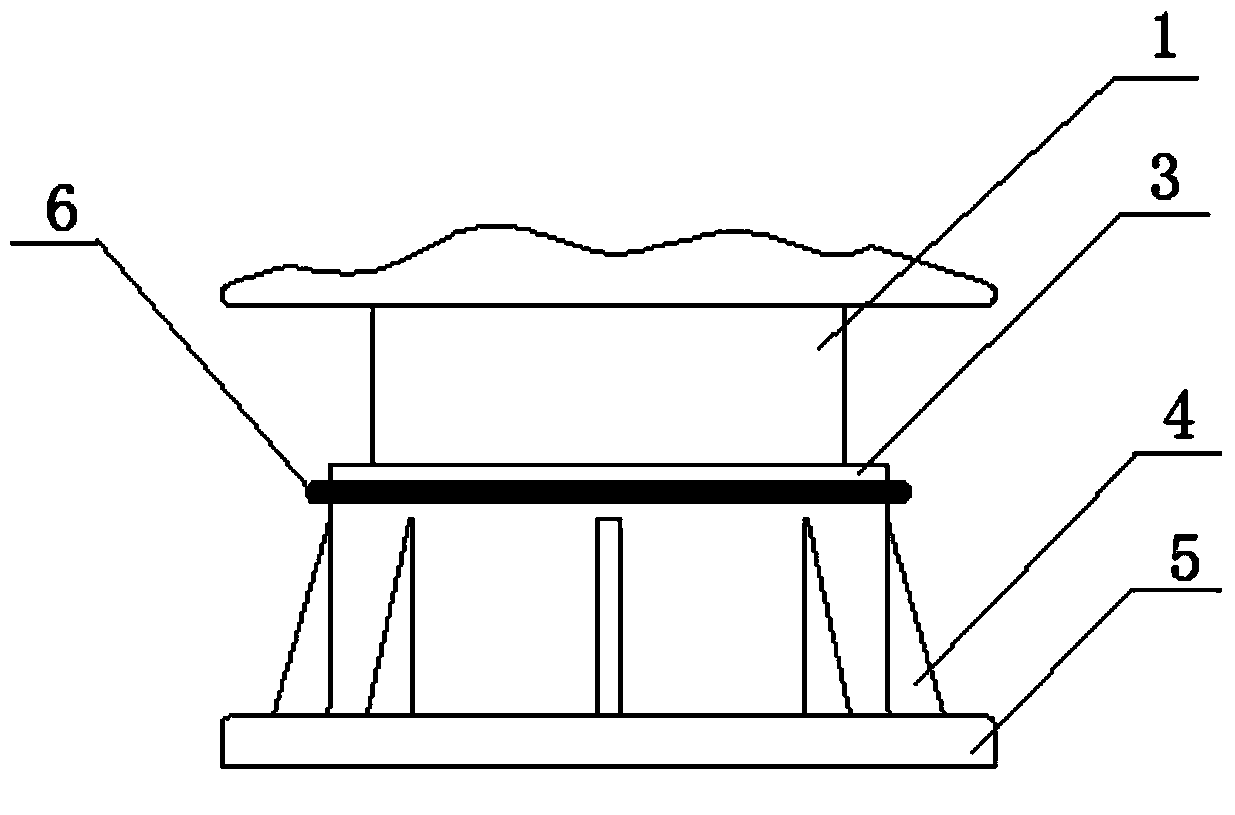

[0039] The casing 3 is installed vertically on the base 5, and the inner and outer walls of the end of the casing 3 are filled with a 90° fillet 7, and a reinforcing rib 4 is welded between the casing 3 and the base 5, and the outer wall of the casing 3 is close to its end Position-welded ring-shaped anti-corona member 6, anti-corona member 6 is made of aluminum alloy casting, aluminum alloy by mass percentage is Si: 0.57%, Fe: 0.55%, Cu: 0.36%, Mn: 0.10%, Mg : 0.85%, Cr: 0.12%, Zn: 0.19%, Ti: 0.11%, the balance is Al.

[0040] A bushing 3 is installed at both ends of the porcelain column 1 of the pillar insulator, and a colloidal layer 2 made of cement with the mark P.O52.5 is added between the bushing 3 and the porcelain column 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fillet | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com