A kind of preparation method of porous carbon sphere loaded m-sn alloy nano particle composite material

A technology of alloy nanoparticles and composite materials, which is applied in the field of preparation of porous carbon sphere-loaded M-Sn alloy nanoparticle composite materials, can solve problems such as unstable cycle performance, capacity decline, and limited development and application, and achieve stable product morphology , uniform heating, broad development prospects and the effect of application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Preparation of porous carbon balls by high temperature spray pyrolysis

[0043] In the first step, weigh 17.4g of sodium chloroacetate, dissolve it in 100mL of deionized water, and add it to the humidifier to produce mist;

[0044] In the second step, 1.2L / min of argon is continuously introduced into the humidifier, and the mist is introduced into the quartz tube of the tube furnace operating at 700°C;

[0045] The third step is to use absolute ethanol to collect the gas discharged from the quartz tube;

[0046] In the fourth step, the product was centrifuged at 5000 rpm and the precipitate was collected, and dried in a vacuum drying oven at 60° C. for 5 hours. The resultant product was a porous carbon ball.

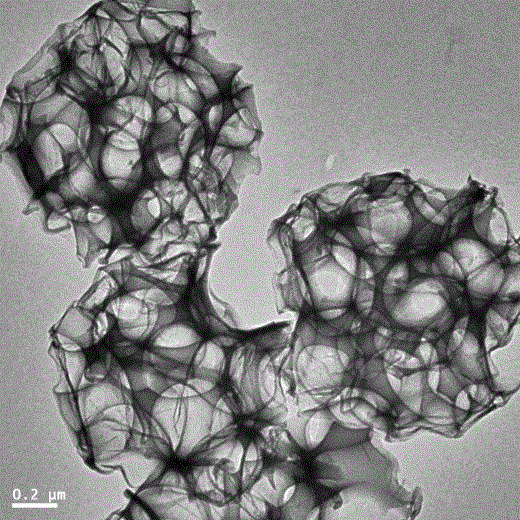

[0047] 2) Synthesis of porous carbon ball supported SnFe alloy nanoparticle composite

[0048] The first step is to accurately weigh 0.025g porous carbon balls dispersed in 50mL triethylene glycol, and then add 0.0564g SnCl 2 ·2H 2 After O ultrasonic mixing, transfer it t...

Embodiment 2

[0053] 1) Preparation of porous carbon balls by high temperature spray pyrolysis

[0054] In the first step, weigh 11.6g of sodium chloroacetate, dissolve it in 100mL of deionized water, and add it to the humidifier to produce mist;

[0055] In the second step, 1.0L / min of argon is continuously introduced into the humidifier, and the droplets are introduced into the quartz tube of the tube furnace operating at 700°C;

[0056] The third step is to use absolute ethanol to collect the gas discharged from the quartz tube;

[0057] In the fourth step, the product was centrifuged at 5000 rpm and the precipitate was collected, and dried in a vacuum drying oven at 60° C. for 10 hours. The resultant product was a porous carbon ball.

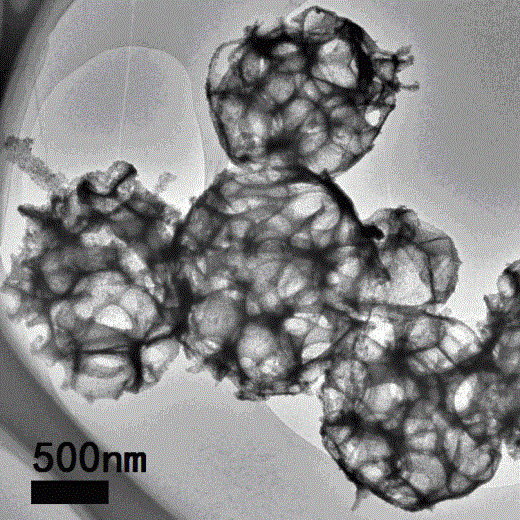

[0058] 2) Synthesis of porous carbon ball supported SnCo nanoparticle composite

[0059] The first step is to accurately weigh 0.030g porous carbon balls dispersed in 50mL triethylene glycol, and then add 0.0564g SnCl 2 ·2H 2 After O ultrasonically mixing, transfer ...

Embodiment 3

[0064] 1) Preparation of porous carbon balls by high temperature spray pyrolysis

[0065] In the first step, weigh 11.6g of sodium chloroacetate, dissolve it in 100mL of deionized water, and add it to the humidifier to produce mist;

[0066] In the second step, 1.0L / min of argon is continuously introduced into the humidifier, and the droplets are introduced into the quartz tube of the tube furnace operating at 650℃;

[0067] The third step is to use absolute ethanol to collect the gas discharged from the quartz tube;

[0068] In the fourth step, the product was centrifuged at 5000 rpm and the precipitate was collected, and dried in a vacuum drying oven at 60° C. for 5 hours. The resultant product was a porous carbon ball.

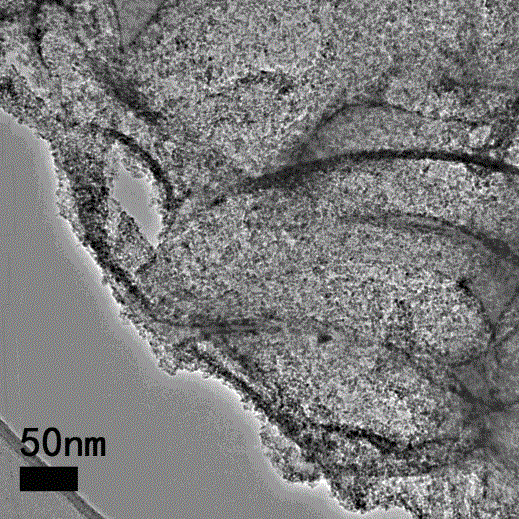

[0069] 2) Synthesis of porous carbon ball supported SnNi nanoparticle composite

[0070] The first step is to accurately weigh 0.025g porous carbon balls dispersed in 50mL triethylene glycol, and then add 0.0564g SnCl 2 ·2H 2 After mixing by ultrasound, transfer it to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com