Method and equipment for manufacturing electrode sheet

A technology of manufacturing device and manufacturing method, which is applied in the field of electrode sheet manufacturing and manufacturing device, can solve the problems of difficult penetration of active substances, large size of the device, etc., and achieve the effect of easy penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0043] (1) Overall structure

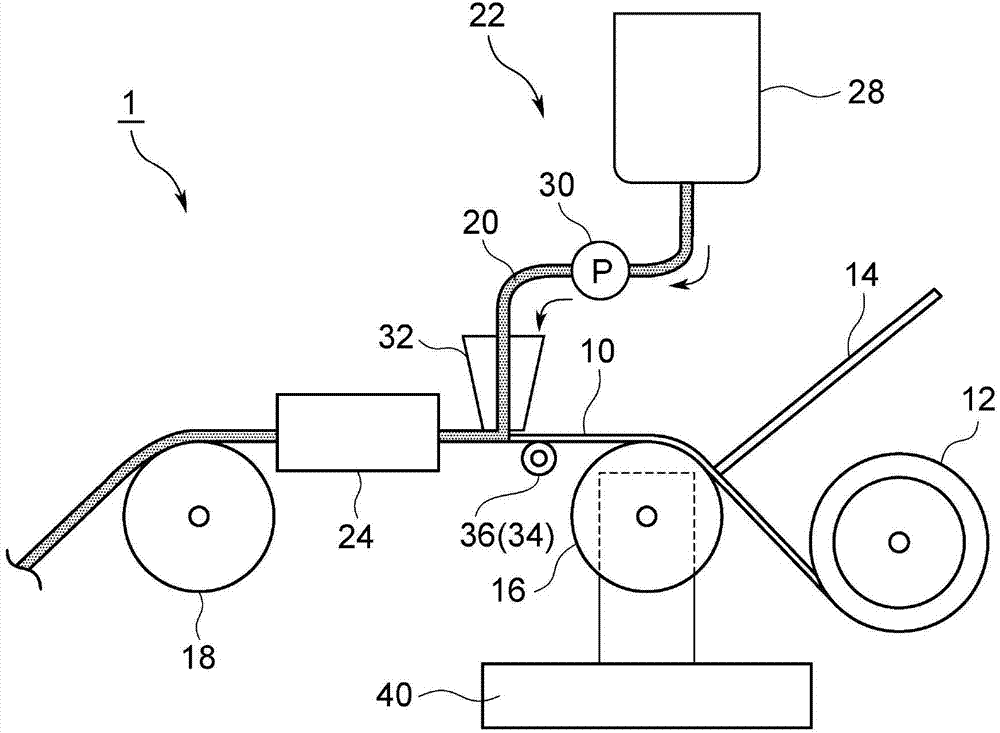

[0044] figure 1 The electrode sheet manufacturing apparatus 1 according to the first embodiment shown includes: a supply roll 12 around which a strip-shaped porous body 10 is wound; a press plate 14 for pressing the porous body 10 against the supply roll 12; The rear roller 16 and the stretching roller 18 of the moving roller that the porous body 10 supplied by the supply roller 12 moves, and the coating part 22 that applies the filler 20 to one surface of the porous body 10 (hereinafter referred to as the surface) , and a drying furnace 24 for drying the porous body 10 coated with the filler 20 . In addition, although the electrode sheet manufacturing apparatus 1 of this embodiment is an apparatus which manufactures the electrode sheet used for a lithium ion secondary battery, it is not limited to use in a lithium ion secondary battery in particular.

[0045] The porous body 10 has a three-dimensional network structure constituting a current c...

no. 2 approach

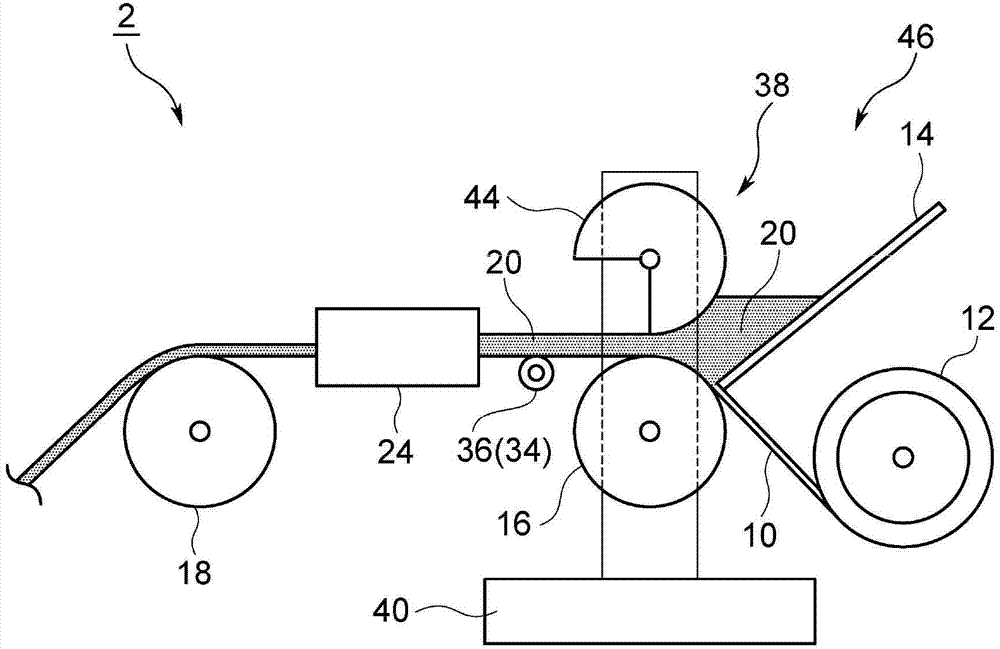

[0063] next, yes figure 2 The electrode sheet manufacturing apparatus 2 according to the second embodiment of the present invention shown will be described. In addition, in this embodiment, the same code|symbol is attached|subjected to the same structure as 1st Embodiment, and description is abbreviate|omitted.

[0064] (1) Overall structure

[0065] The electrode sheet manufacturing apparatus 2 of the present embodiment is mainly different from the above-mentioned first embodiment in that the coating unit is configured to apply the filler 20 using the comma coating method (comma coater method). That is, in this embodiment, the supply roll 12, the platen 14, the back roll 16, the stretching roll 18, the coating part 38, the drying oven 24, and the vibration application part 34 are provided.

[0066] The coating section 38 applies the filler 20 by a comma coating method. The coating unit 38 has a knife roll 44 formed on an upper portion of the rear roll 16 provided on the b...

no. 3 approach

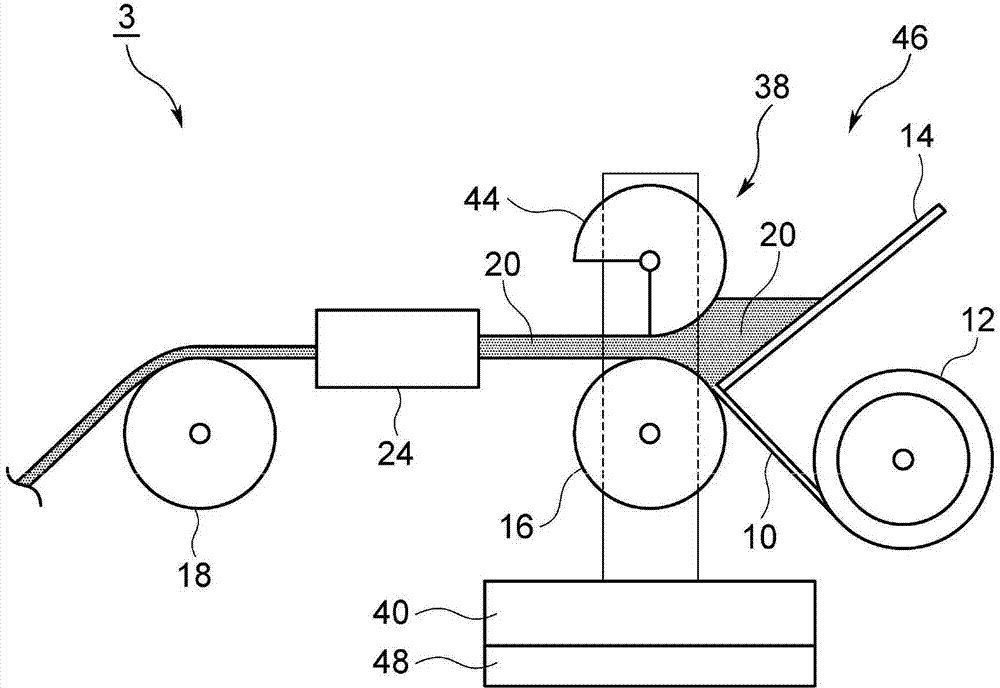

[0074] next, yes image 3 The electrode sheet manufacturing apparatus 3 according to the third embodiment of the present invention shown will be described. In addition, in this embodiment, the same code|symbol is attached|subjected to the same structure as 2nd Embodiment, and description is abbreviate|omitted.

[0075] (1) Overall structure

[0076] The electrode sheet manufacturing apparatus 3 of the present embodiment differs from the above-described second embodiment in that the vibration imparting unit 48 is attached to the base 40 that rotatably supports the rear roller 16 and the knife roller 44 .

[0077] The vibration imparting unit 48 of the present embodiment imparts vibration of a desired frequency to the base 40 . Specifically, the vibration imparting unit 48 is provided between the base 40 and a floor (not shown), and imparts vibration to the base 40 itself. Thereby, the rear roller 16 and the knife roller 44 supported by the base 40 vibrate. The vibration imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com