Storing and mixing devices

A technology of mixing equipment and equipment, applied in the directions of mixers, transportation and packaging, chemical instruments and methods, etc., can solve the problems of distance, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

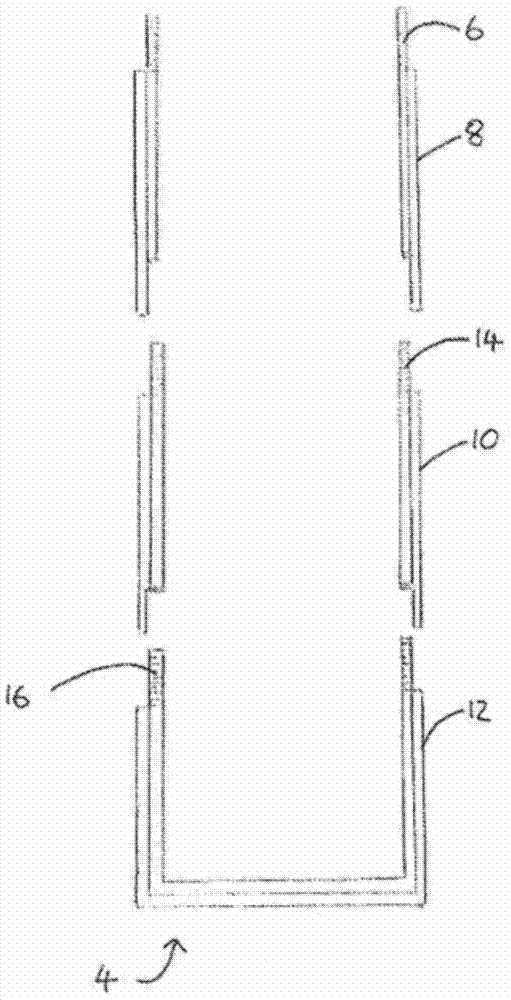

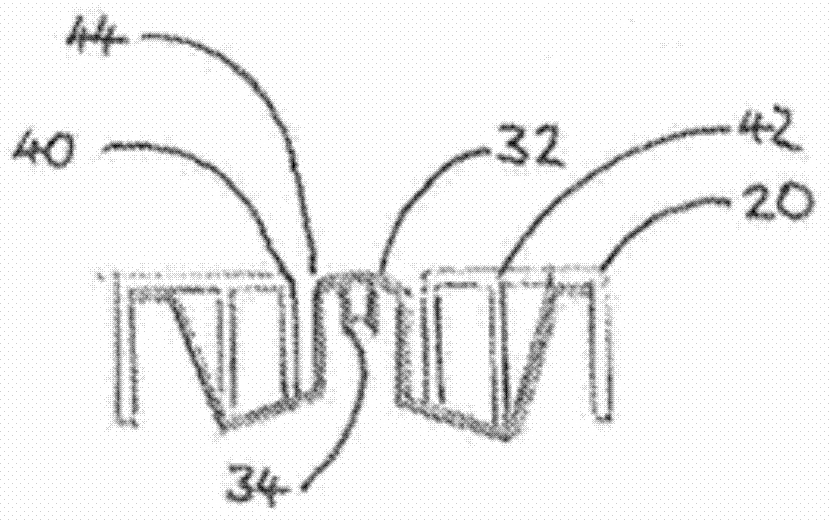

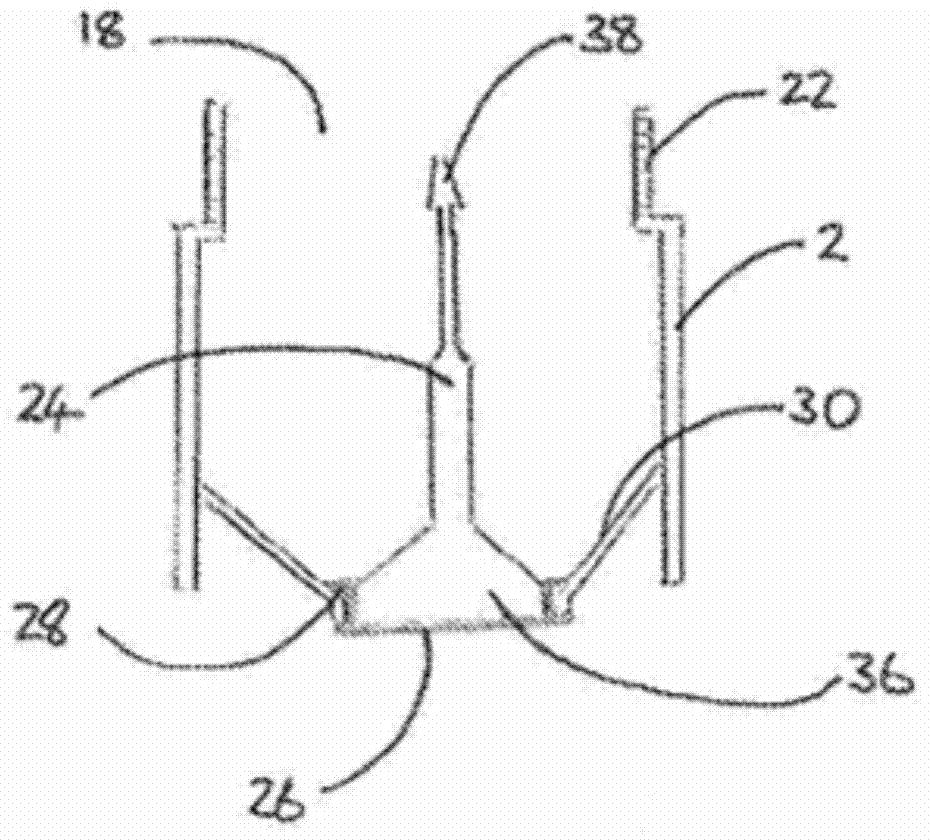

[0033] Referring to the accompanying drawings below, figure 1 , 2 and 3 show components of the apparatus comprising the storage and mixing device 1, as described in more detail below. Figure 4 The components of the storage and mixing device 1 are shown connected together prior to use.

[0034] The storage and mixing device 1 comprises a first chamber 2 and a second chamber 4 removably connected to each other by threaded connection means 6 . available from figure 1 As seen in FIG. 2 , the second chamber 4 comprises three removable modules 8 , 10 , 12 each having screw-type connection means 6 , 14 , 16 . The shape and dimensions of the modules 8, 10, 12 are chosen to fit them together. In an embodiment of the invention, threaded connection means 6 are used to connect the first chamber 2 to the second chamber 4 .

[0035] Said first chamber 2 and the detachable modules 8, 10, 12 forming the second chamber 4 are made of thermoplastic material. image 3 The first chamber 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com