Structure of LED, and fabricating method

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of affecting the pass rate of processing technology, the efficiency of light-emitting diodes, and the fragility of light-emitting diodes, so as to facilitate heat dissipation, increase brightness, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

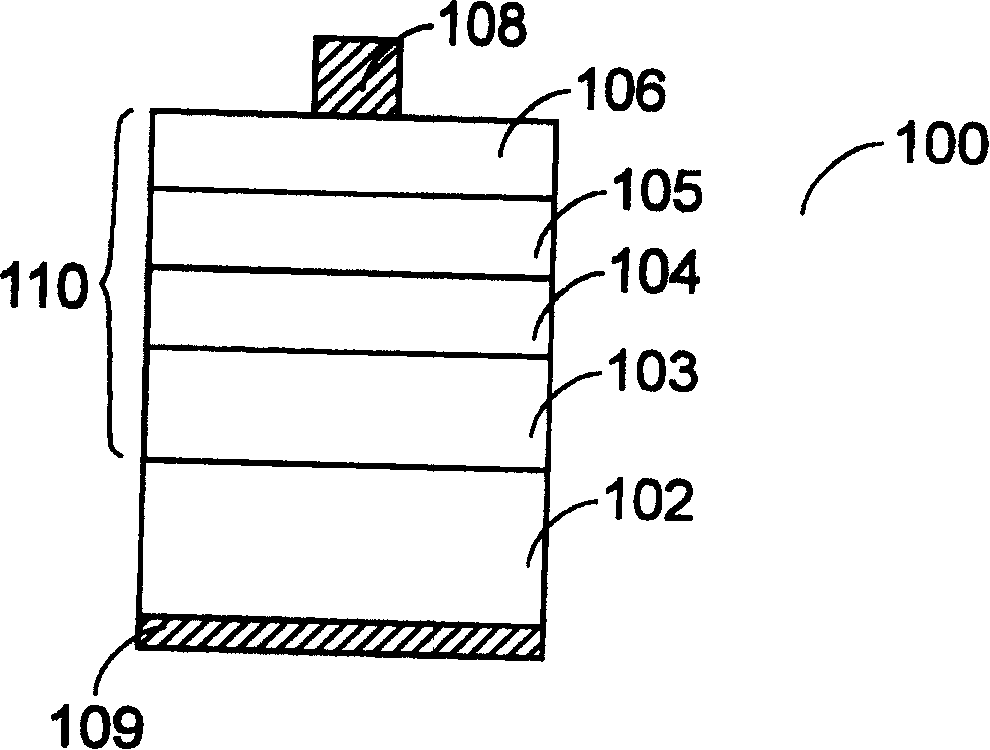

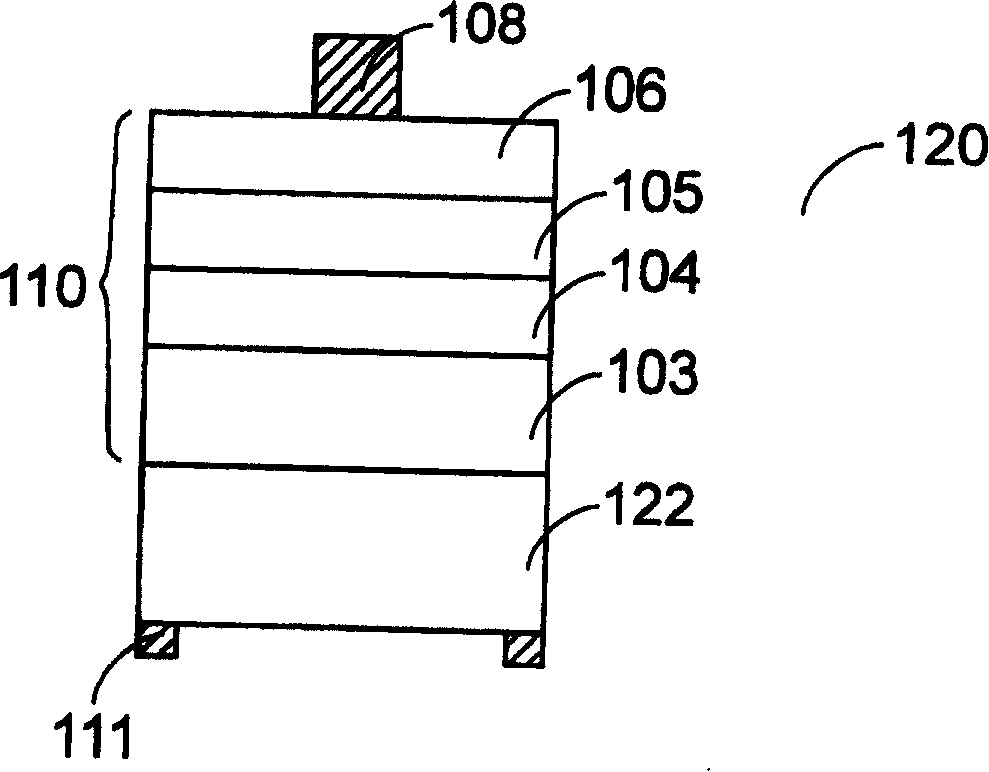

[0080] In view of the above shortcomings, the present invention proposes a chip bonding light emitting diode to solve the shortcomings of known light emitting diodes manufactured by chip bonding technology. Please refer to Figure 9 , which is a schematic diagram of the structure of the grain-bonded light-emitting diode of the present invention. The structure of the die-bonded light-emitting diode 500 includes a first electrode 508, a light-emitting region 510, an ohmic contact point (Ohmic Contact Dot) 520, a reflective layer 522, a barrier layer (Barrier Layer) 524, an adhesive layer (Eutectic Layer) 526, a visual It is the metal layer (Metal Layer) 528 of the second electrode, and the sub-adhesive substrate (Submount) 530 . Among them, the first electrode 508, the light emitting region 510, the Ohmic Contact Dot (Ohmic Contact Dot) 520, the reflective layer 522, the barrier layer (Barrier Layer) 524, and the paste layer 526 are regarded as a chip (Chip) 550, and the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com