Inverted LED (light emitting diode) chip and manufacturing method thereof

A LED chip and flip-chip technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor current diffusion effect of P-type gallium nitride layer, decreased light efficiency of flip-chip, and rise of chip turn-on voltage. Achieve low resistance ohmic contact, reliable performance, and prevent light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

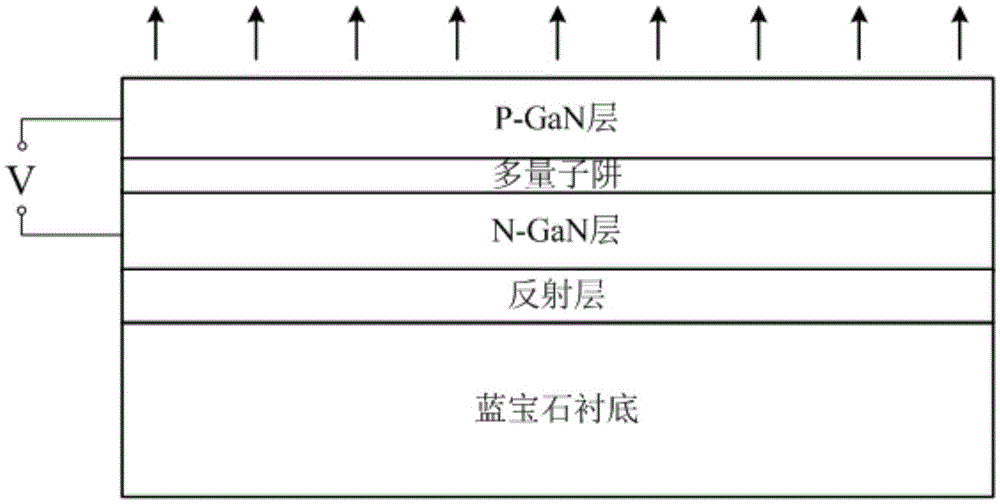

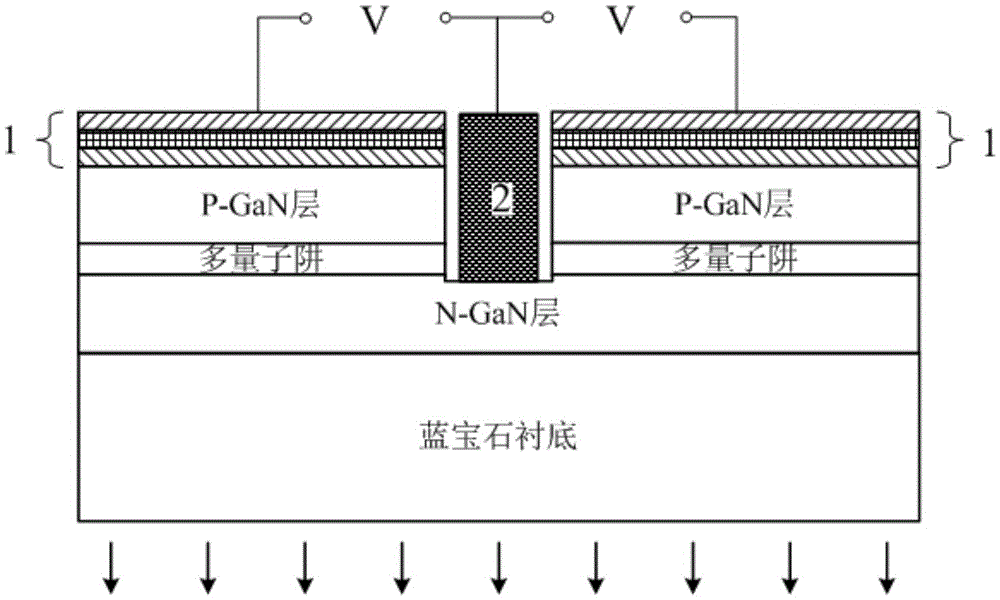

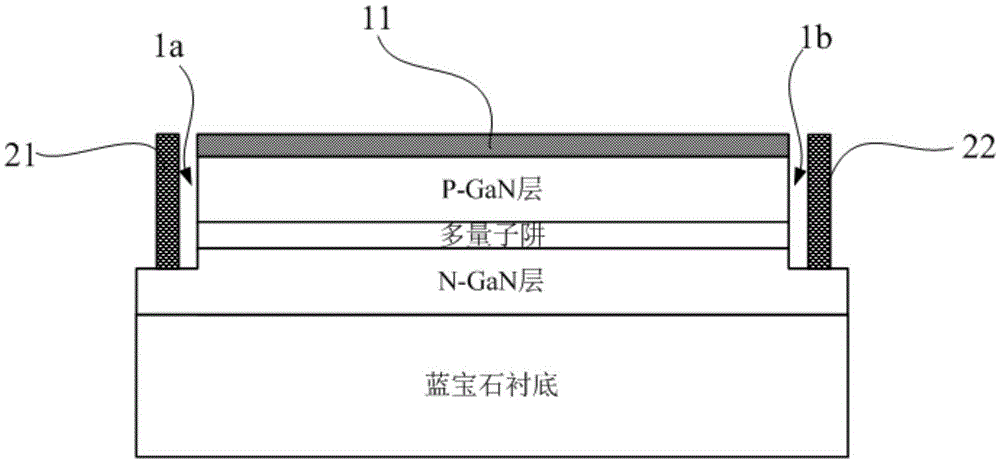

[0041] Such as image 3 , 4 As shown, in a preferred embodiment of the present invention, a flip-chip LED chip is provided. The flip-chip LED chip includes a sapphire substrate and an N-type gallium nitride layer, a multi-quantum well structure layer and a P-type gallium nitride layer distributed upwards from the upper surface of the sapphire substrate, which is a mirror symmetrical structure. The N-type gallium nitride layer, the multi-quantum well structure layer and the P-type gallium nitride layer constitute an epitaxial structure, and the epitaxial structure is perpendicular to the longitudinal section of the symmetry plane of the flip-chip LED chip (in this application, gallium nitride-based flip-chip LED The longitudinal section of the chip and the epitaxial structure refers to the section perpendicular to the symmetry plane) into a convex shape.

[0042] The flip-chip LED chip of this structure can form N-type gallium nitride layer, multi-quantum well structure layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com