Method for improving precision of pendulum gyroscope north seeker based on improvement of reference mirror process

A technology of process improvement and north finder, which is applied in the field of mechanical manufacturing technology, can solve the problems such as the easy change of the installation position, and achieve the effect of eliminating the glue assembly process, improving the installation stability, and improving the assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

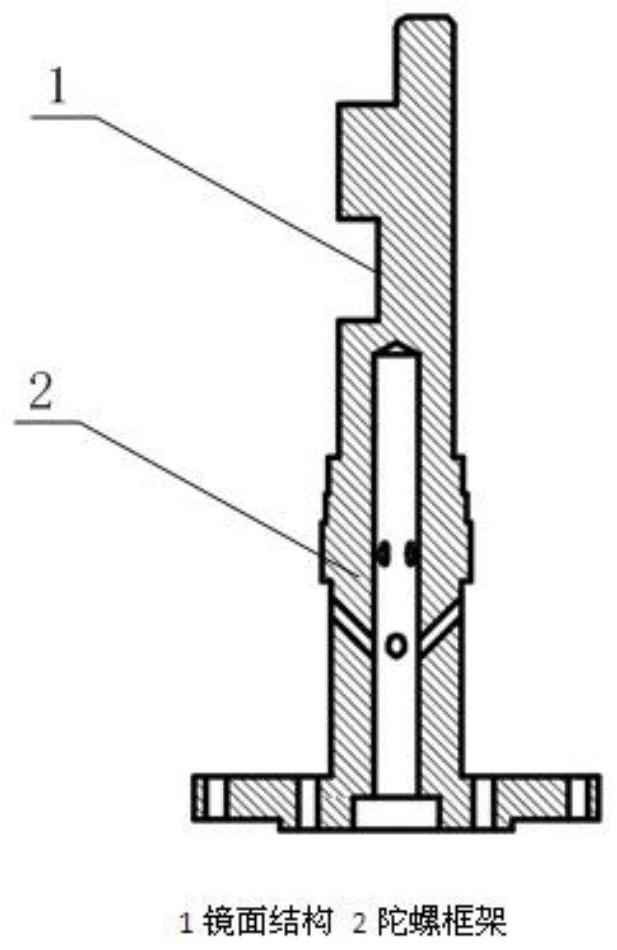

[0029] A method for improving the accuracy of a pendulum gyro north finder based on the improvement of the reference mirror process, the object of process improvement is the reference mirror on the gyro frame 2, such as figure 2 As shown, the improved reference mirror is a mirror structure 1 integrally formed on the gyroscope frame 2 and polished and coated.

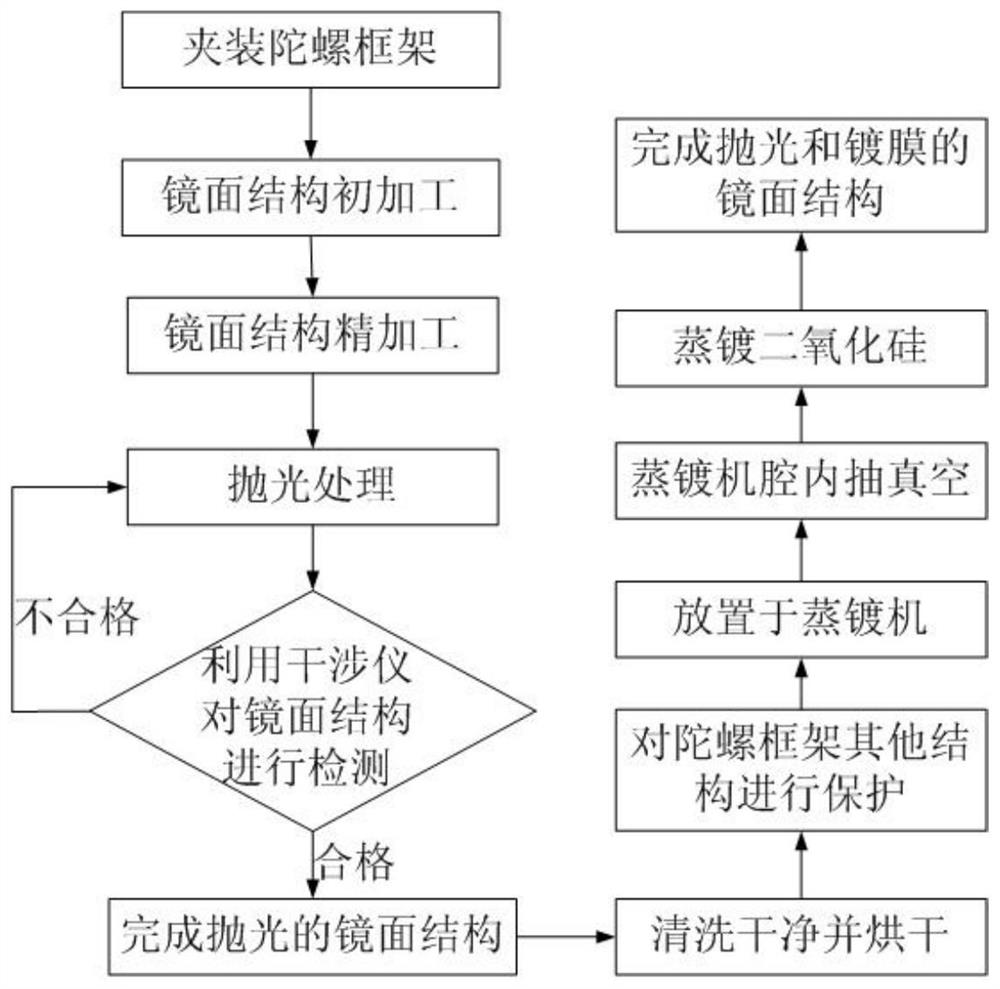

[0030] The specific steps are as figure 1 Shown include:

[0031] Step 1, making a mirror structure on the upper part of the gyro frame, and performing preliminary processing on the mirror structure integrally formed with the gyro frame;

[0032] The concrete steps of described step 1 include:

[0033] (3) Carry out turning processing to the mirror structure, and process each outer circle and each end face of the gyro frame;

[0034] (4) Milling the gyroscope frame, and after aligning wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com