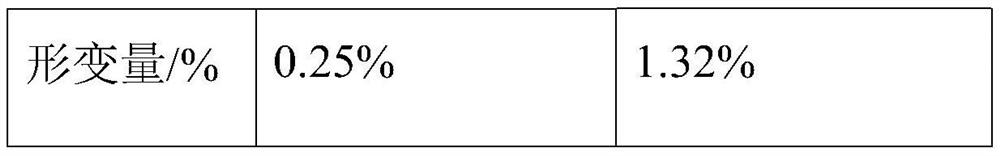

Zirconia powder cake, preparation method and application, and adjustment method for its shrinkage performance

A technology of zirconia powder and zirconia, which can be used in applications, pharmaceutical formulations, dental preparations, etc., can solve problems such as cracking, deformation, and inconsistent shrinkage behavior of zirconia powder, and achieve avoidance of shape distortion, high deformation stability, and shrinkage Effects of Behavioral Controllable Modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Provide the preparation of multiple groups of zirconia powders (A1, A2, A3) with different yttrium content, the yttrium content of zirconia powder A1 is 3mol%, the yttrium content of zirconia powder A2 is 4mol%, and the yttrium content of zirconia powder A3 is 5mol% , the preparation method comprises the following steps:

[0072] (1) Preparation of zirconia powder A1 specifically includes the following steps: (1a) mixing zirconium nitrate and yttrium nitrate in a molar ratio of 97:6 and dissolving in water, adjusting the pH to 8-10; (1b) raising the temperature of the reaction system to 160 ℃ for hydrothermal synthesis; (1c) after the hydrothermal synthesis product is washed and dried, the powder is calcined and heat-treated at 950 ℃, ground, dispersed, and granulated to obtain zirconia powder A1 (yttrium content 3mol%);

[0073] (2) preparing zirconia powder A2, specifically comprising the following steps: (2a) calculating the hydrothermal synthesis temperature accordi...

Embodiment 2

[0095] Provide the preparation of multiple groups of zirconia powders (B1, B2, B3) with different yttrium content, the yttrium content of zirconia powder B1 is 5mol%, the yttrium content of zirconia powder B2 is 4mol%, and the yttrium content of zirconia powder B3 is 3mol% , the preparation method comprises the following steps:

[0096] (1) Preparation of zirconia powder B1 specifically includes the following steps: (1a) mixing zirconium nitrate and yttrium nitrate in a molar ratio of 95:10 and dissolving in water, adjusting the pH to 8-10; (1b) heating the reaction system to 160 ℃ for hydrothermal synthesis; (1c) after the hydrothermal synthesis product is washed and dried, the powder is calcined and heat-treated at 950 ℃, ground, dispersed, and granulated to obtain zirconia powder B1 (yttrium content 5mol%);

[0097] (2) preparing zirconia powder B2, specifically comprising the following steps: (2a) calculating the hydrothermal synthesis temperature according to formula (I):...

Embodiment 3

[0118] Provide the preparation of multiple groups of zirconia powders (C1, C2, C3) with different yttrium content, the yttrium content of zirconia powder C1 is 4mol%, the yttrium content of zirconia powder C2 is 6mol%, and the yttrium content of zirconia powder C3 is 2mol% , the preparation method comprises the following steps:

[0119](1) Preparation of zirconia powder C1 specifically includes the following steps: (1a) mixing zirconium nitrate and yttrium nitrate in a molar ratio of 96:8 and dissolving in water, adjusting the pH to 8-10; (1b) heating the reaction system to 160 ℃ for hydrothermal synthesis; (1c) after the hydrothermally synthesized product is washed and dried, the powder is calcined and heat-treated at 950°C, ground, dispersed, and granulated to obtain zirconia powder C1;

[0120] (2) preparing zirconia powder C2, specifically comprising the following steps: (2a) calculating the hydrothermal synthesis temperature according to formula (I): ΔT 水热合成 =-8.5×2=-17°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com