Shaving clamp used for gear of synchronizer

A synchronizer and gear technology, which is applied to gear tooth manufacturing devices, components with teeth, belts/chains/gears, etc. Stable clamping gear, stable clamping, ensuring the effect of shaving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

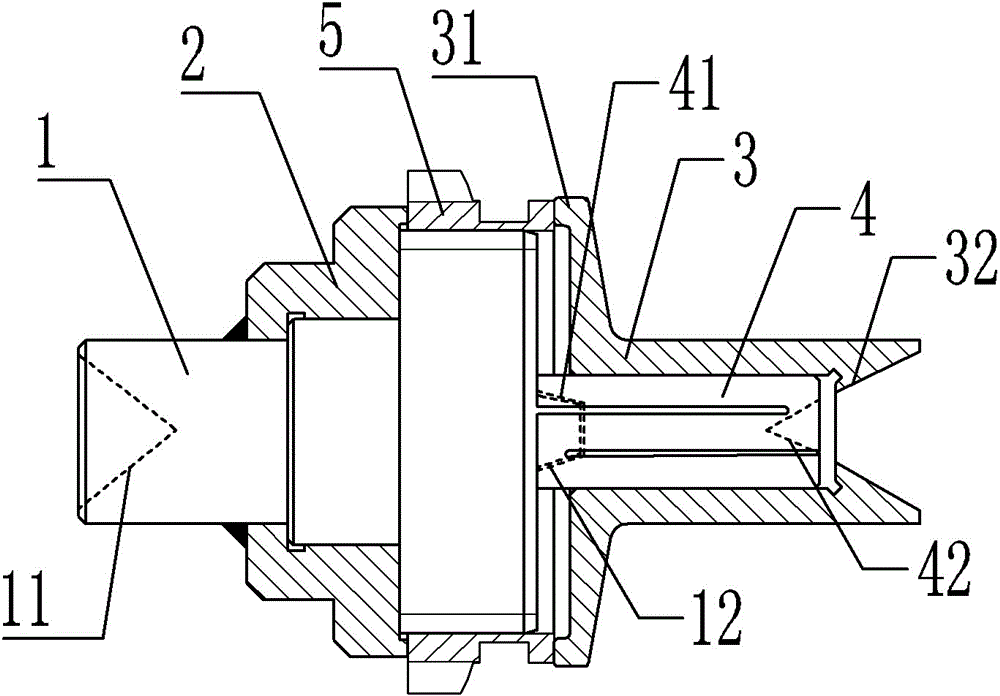

[0012] Such as figure 1 The shaving jig for synchronizer gear shown includes mandrel 1, first central positioning hole 11, cone truncated 12, positioning sleeve 2, ferrule 3, chuck 31, second central positioning hole 321, expansion sleeve 4, frustum of cone hole 41, expansion sleeve conical hole 42 and gear 5.

[0013] In this embodiment, the mandrel 1 is a two-step mandrel with a small-diameter shaft section, a middle-diameter shaft section, and a large-diameter shaft section. The first central positioning hole 11 is a conical hole, and the first central positioning hole 11 is arranged along the axial direction of the mandrel. On the small-diameter shaft section of the mandrel 1, when the gear is clamped, it is tightened by the top of the top column of the machine tool. The inner circle of the positioning sleeve 2 matches the shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com