Real-time height compensating knife stone device

A technology of real-time compensation and high compensation, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of high manufacturing cost, tool sharpness, service life loss, skill level of sharpeners, and large consumption of sharpening stones and other problems, to achieve the effect of low manufacturing cost and use cost, reducing the number of hidden fault points, and low manufacturing and use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

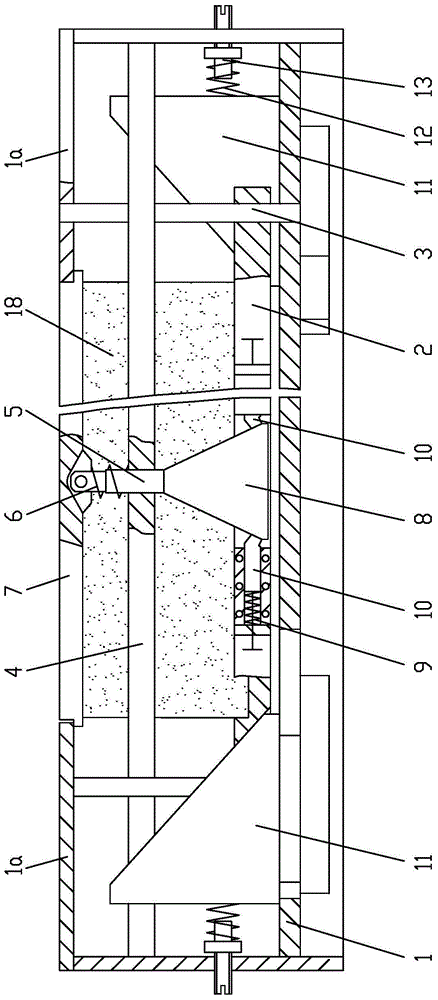

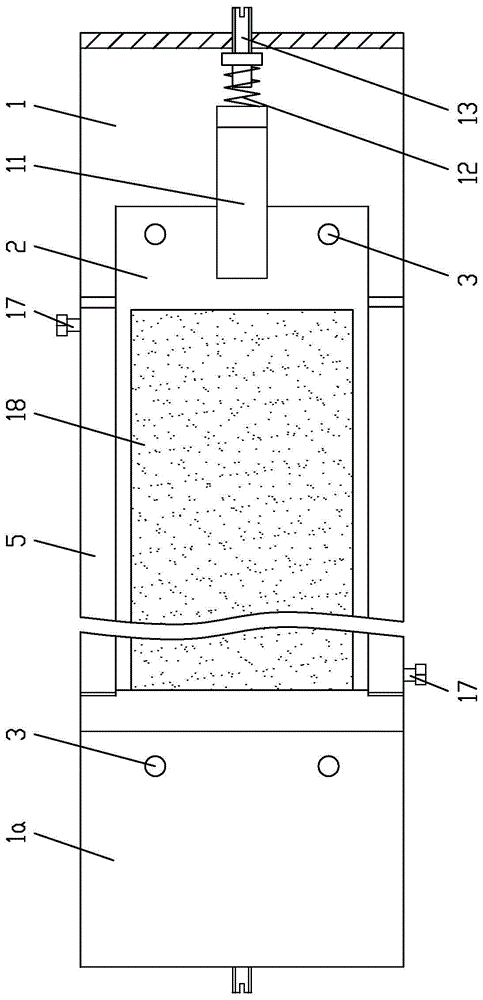

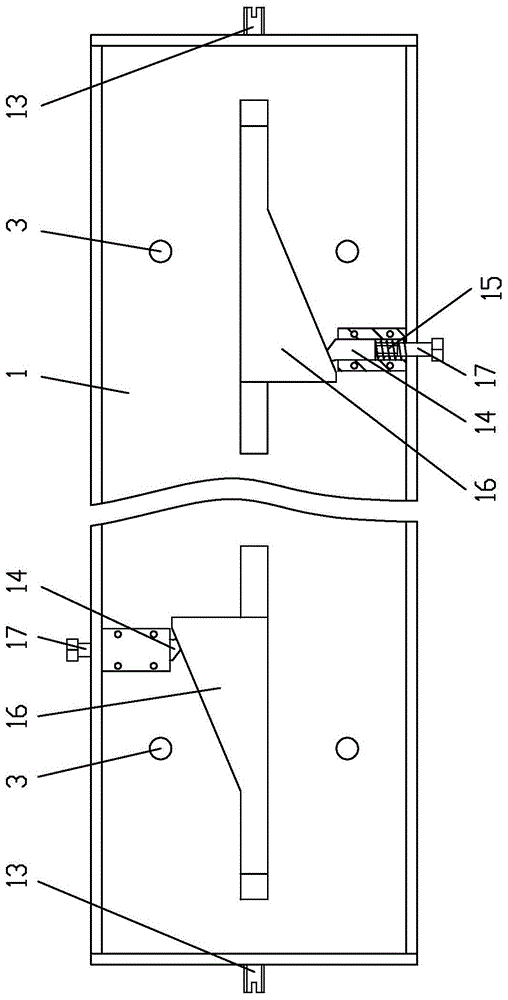

[0017] see figure 1 , figure 2 , image 3 , Figure 4 , a height real-time compensation whetstone device, including a machine base 1 and a whetstone mounting seat 2 located thereon, a height compensation device and a mounting seat support device, and the machine base 1 is provided with a whetstone mounting seat 2. The guide column 3 for vertical lifting and guiding, the top end of the wall at both ends of the machine base 1 is provided with a guide plate 1a, and the whetstone mounting seat 2 is fixed by a strip whetstone 18, the top surface of the strip whetstone 18 is connected to the top surface of the whetstone. The top surface of the guide plate 1a is located in the same plane; the height compensation device is provided with two sets distributed on both sides of the whetstone mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com