Vibrating burnisher

A finishing machine and vibrating shaft technology, which is applied to surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc. It can solve the problems of affecting the amplitude of the container, high maintenance costs, and heavy vibration motors. , to save equipment cost, facilitate maintenance and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

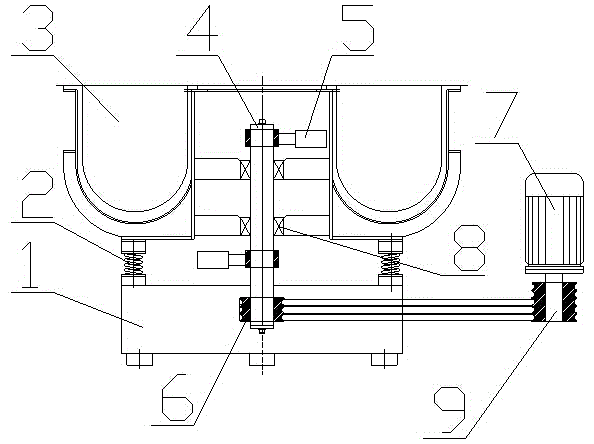

[0010] Embodiments of the present invention: the structure of the vibration finishing machine is as figure 1 As shown, during production, a base 1 is first welded with angle iron and thin steel plate, a spring 2 is installed on the base 1, and the other end of the spring 2 is correspondingly connected to the spring fixing point of the container 3; The bearing 8 is installed, the inner ring of the bearing 8 cooperates with the vibrating shaft 4, and two eccentric blocks 5 are connected to the vibrating shaft 4, and the two eccentric blocks 5 are respectively located on the symmetrical sides of the bearing 8, and at the same time, the bottom end of the vibrating shaft 4 is also Belt pulley 6 is installed, and motor 7 is set outside vibration finishing machine base 1, and belt pulley 9 is installed on the output shaft of motor 7, and belt pulley 6 is connected with the belt pulley 9 on the output shaft of motor 7 by belt.

[0011] When in use, the motor 7 arranged outside the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com